Introduction

Teeth are the best measure of individuality of a person. Teeth used in the fabrication of dentures should demonstrate optimum physical and mechanical properties to withstand rigorous demands of masticatory functions such as chewing, biting, shearing of food and simultaneously superior esthetics particularly in the anterior region of the mouth. Acrylic resin (PMMA) and porcelain teeth are the most commonly used ones. But the fracture of acrylic resin teeth from a maxillary denture, is not uncommon especially the teeth in the anterior region[1],[2].Over the years, many researchers have attempted to improve the bond strength of denture teeth to an acrylic resin denture base, either by chemical treatment or by mechanical modification of the ridge lap portion of the denture tooth. However, the results have been mixed and conflicting. This study was carried out to determine whether certain modifications to the ridge lap surface of the teeth would improve the bond strength between the artificial cross linked acrylic resin teeth and denture bases.

Materials and method

The method used in the study was divided into the following steps -

I. Fabrication of triangular wax blocks for arranging acrylic resin teeth

A triangular wax block having each side 3.5 cm and length of 4.5 cm with 60o angulation was fabricated using modelling wax (Rolex Modelling Wax No. 2, Ashoo Sons, Delhi) and checked using graph paper (Fig. 1). Its impression was made in polyvinyl siloxane putty material (3M ESPE AG, Seefeld Germany) to standardize the size of wax blocks and similar blocks were fabricated by pouring molten wax in the polyvinyl siloxane mould.

| Fig. 1 Wax Block

|

II. Preparation of ridge lap surfaces of hundred central incisors

100 cross-linked acrylic resin central incisors (Acryrock, Ruthinium Dental Products Pvt. Ltd., Gujarat) of same mould were taken and divided into 5 groups, 20 in each group

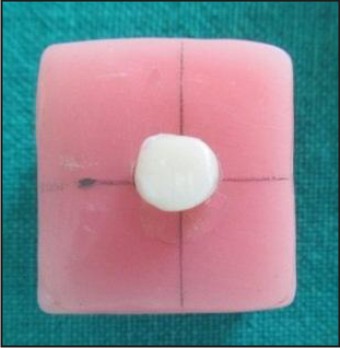

Group A: Teeth without any modification to the ridge lap surface (control group) (Fig. 2).

| Fig. 2 Unmodified Surface

|

Group B: The glazed ridge lap surfaces of teeth were roughened using sandpaper (No. 120 – John Oakey and Mohan Ltd., Ghaziabad) (Fig. 3). 23 cm long and 2cm wide strips of sandpaper were cut and ten strokes along the entire length of strip were given on the ridge lap surface of each tooth. A single strip of sandpaper was used for each tooth.

| Fig. 3 Ridge Lap Surface Roughened By Sandpapering

|

Group C: Teeth modified by preparing two vertical grooves labiopalatally on the ridge lap surfaces. The grooves were prepared using straight fissure bur no. 557 (S.S. White, Inc., New Jersey),which were 1mm in depth and 1mm in width (Fig. 4).

| Fig. 4 Ridge Lap Surface Modified By Vertical Grooves

|

Group D: Teeth modified by preparing a diatoric recess on the ridge lap surfaces with a round bur no. 6 (S.S. White, Inc., New Jersey),2 mm in diameter (Fig. 5).

| Fig. 5 Ridge Lap Surface Modified By Diatoric Recess

|

Group E:Teeth were kept as such and monomer application (Trevalon Heat Cure Polymethyl methacrylate resin, Dentsply India Pvt. Ltd., Gurgaon)was done with a brush just before packing the resin (Fig. 6).

| Fig. 6 Ridge Lap Surface Modified By Monomer Application

|

The position of vertical grooves and diatoric recess was standardized using an acrylic mould on which the teeth could be mounted. The teeth were also stabilized in the same mould while modifying the ridge lap surfaces.

III. Arrangement of teeth on triangular wax blocks

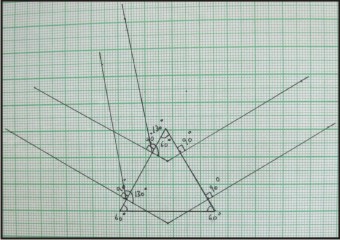

On a graph paper, an equilateral triangle of dimensions 3.5 cm was drawn and lines were drawn on both sides of the triangle at an angle of 130o (Fig. 7). This was done to standardize the position and angulation of the teeth on the wax blocks.

| Fig. 7 Triangle With Angulations On Graph Paper

|

Ten teeth were arranged on each block (5 on each side) at an angle of 130o with the help of graph paper (Fig. 8). This angulation was chosen to simulate the average angle of contact between maxillary and mandibular teeth in Class I occlusion. Teeth of different groups were placed on different wax blocks.

| Fig. 8 Wax Block With Mounted Teeth

|

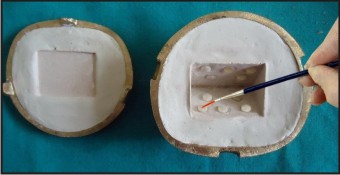

IV. Processing of wax blocks

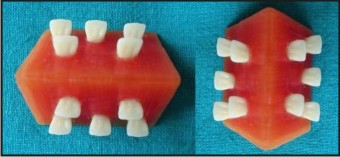

Triangular wax blocks with teeth were processed in varsity pattern dental flask, following standard procedure according to manufacturer’s instructions about ratio and manipulation of Trevalon Heat Cure Polymethyl methacrylate resin (Dentsply India Pvt. Ltd., Gurgaon). Acrylic blocks with mounted teeth were then finished, rechecked on graph paper and stored in water (Fig. 9).

| Fig. 9 Finished Acrylic Block After Deflasking

|

V. Measurement of bond strength

The acrylic wax blocks were stabilized in a fixture so that no movement occurred during load application and subjected to Instron Universal Testing Machine (Fig. 10). Force was applied by a 1.5 mm diameter stainless steel pin at a crosshead speed of 5 mm/min until detachment of teeth occurred.

| Fig. 10 Testing In Universal Testing Machine

|

Results

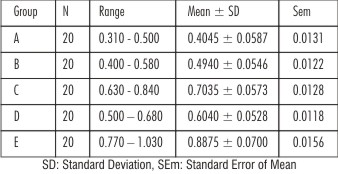

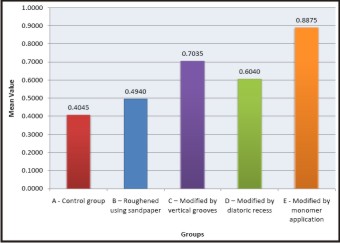

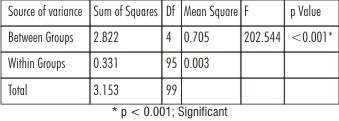

The readings were subjected to statistical analysis by applying Analysis of Variance and Post Hoc Tukey HSD tests (for multiple comparisons) and graphs were plotted. The samples modified by monomer application showed the highest mean debonding force of 0.8875 KN followed by vertical grooves (0.7035 KN), diatoric recess (0.6040 KN) and sandpapered group (0.4940 KN). All the mechanical modifications as well as monomer application showed an improvement in bond strength over the control group (0.4045 KN) (Table 1 and Graph 1). On applying one way Analysis of Variance, a statistically significant difference was seen between the strength with different ridge lap modifications of the samples within groups and between groups i.e. p < 0.001 (Table 2).

| Table 1 : Bond Strength (Mean ± Sd) Values

|

| Graph 1 : Mean Shear Compressive Load In Different Groups

|

| Table 2 : One Way Anova (Analysis Of Variance)

|

Discussion

Harold Vernon first introduced the use of methyl methacrylate in the form of a powder and liquid to be used as a denture base in the 1930’s[3].Debonding of denture teeth from a denture base has remained a major problem in prosthodontic practice. Studies that have evaluated the frequency of various denture repairs have found tooth debonding/fracture to be the most frequentin both complete and partial dentures followed by the midline fracture of complete dentures[4], [5]. The lack of adequate bonding is believed to be the result incompatible surface conditions at the tooth/base interface. This incompatibility is brought about by two factors - contamination of the surfaces particularly by wax and possibly by sodium alginate as separating medium and the difference in the structure of the two components due to their different processing[6].

Sandpapered group showed higher bond strength values as compared to the control group. The improvement in bond strength on grinding was also reported by various authors[7],[8],[9],[10],[11],[12]. Contradictory results were obtained by some authors[13],[14].

Vertical grooves showed higher values than control group, surface roughened group and with diatoric recess. Similar results were obtained by some others[15]. No improvement in bond strength on grooving was obtained in some studies[16].

Group with diatoric on the ridge lap surface showed higher bond strength values as compared to the control group and surface roughened group. A diatoric significantly decreased the failure load in one type of resin but actually decreased it in another resin. The improvement in bond strength by placement of diatorics was also reported by some others[17],[18].

Monomer modified group showed highest bond strength as compared to control group as well as other modified groups. Similar results were also obtained by some authors[19], [20], [21], [22].

Conclusion And Summary

Modification of the ridge lap surface of maxillary anterior teeth by monomer application or mechanical modification is hence recommended to enhance their bond strength to the denture bases. Monomer application is the easiest method and also provides the highest bond strength values without any extra cost and time.Further in vivo studies on various methods to increase the bond strength of teeth and denture bases should be carried out.

References

1. Cardash HS, Liberman R, Helft M. The effect of retention grooves in acrylic resin teeth on tooth denture-base bond. J Prosthet Dent 1986;55:526-28.

2. Cardash HS, Applebaum B, Baharav H, Liberman R. Effect of retention grooves on tooth-denture base bond. J Prosthet Dent 1990;64:492-6.

3. Kelly EB. Has the advent of plastics in dentistry proved of great scientific value? J Prosthet Dent 1951;1:168-76.

4. Barpal D, Curtis DA, Finzen F, Perry J, Gansky SA. Failure load of acrylic resin denture teeth bonded to high impact acrylic resins. J Prosthet Dent 1998;80:666-71.

5. Darbar UR, Huggett R, Harrison A. Denture fracture – a survey. Br Dent J 1994;74: 591-4.

6. Cunningham JL, Benington IC. A survey of the pre-bonding preparation of denture teeth and the efficiency of dewaxing methods. J Dent 1997;2:125-8.

7. Civjan S, Huget EF, Simon LB. Modifications of the fluid resin technique. J Am Dent Assoc 1972;85:109-12.

8. Caswell CW, Norling BK. Comparative study of the bond strengths of three abrasion-resistant plastic denture teeth bonded to a cross-linked and a grafted, cross-linked denture base material. J Prosthet Dent 1986;55:701-708.

9. Amin WL. Improving bonding of acrylic teeth to self-polymerizing denture base resins. Saudi Dental Journal 2002;14:15-19.

10. Chung KH, Chung CY, Chung CY, Chan DCN. Effect of pre-processing surface treatments of acrylic teeth on bonding to the denture base. J Oral Rehabil 2008;35:268-275.

11. Bragaglia LE, Prates LHM, Calvo MCM. The role of surface treatments on the bond between acrylic denture base and teeth. Braz J Oral Sci 2009;20:156-61.

12. Amarnath GS, Indra Kumar HS, Muddugangadhar BC. Bond strength and tensile strength of surface treated resin teeth with microwave cured and heat cured acrylic resin denture base: An in-vitro study. International Journal of Clinical Dental Science 2011;2:27-31.

13. Cunningham JL, Benington IC. An investigation of the variables which may affect the bond between plastic teeth and denture base resin. J Dent 1999;27:129-35.

14. Spratley MH. An investigation of the adhesion of acrylic teeth to dentures. J Prosthet Dent 1987;58:389-92.

15. Azad AA, Siddiqui A, Jawad A, Jia M, Ali T. Effect of mechanical modification of acrylic resin denture teeth bonded to acrylic denture base. Pakistan Oral & Dental Journal 2012;32:149-153.

16. Saavedra G, Neisser MP, Sinhoreti MAC, Machado C. Evaluation of bond strength of denture teeth bonded to heat polymerized acrylic resin denture bases. Braz J Oral Sci 2004;3:458-64.

17. MengGK, Chung KH, Fletcher-Stark ML,Zhang H. Effect of surface treatments and cyclicloading on the bond strength of acrylic resin denture teeth with autopolymerized repair acrylic resin. J Prosthet Dent 2010;103:245-52.

18. Takahashi Y, Chai J, Takahashi T, Habu T. Bond strength of denture teeth to denture base resins. Int J Prosthodont 2000;13:59-65.

19. Geerts GAVM, Jooste CH. A comparison of the bond strengths of microwave- and water-bath cured denture material. J Prosthet Dent 1990;70:406-09.

20. Nishigawa G, Maruo Y, Okamoto M, Oki K, Kinuta Y, Minagi S, Irie M, Suzuki K. Effect of adhesive primer developed exclusively for heat-curing resin on adhesive strength between plastic artificial tooth and acrylic denture base resin. Dent Mater J 2006;25:75-80.

21. Beuer F, Erdelt KJ, Friedrich R, Bogai KK, Eichberger M. Retention and fracture resistance of acrylic denture teeth on the denture base. Deutsche Zahnarzliche Zeitschrift 2006;61:147-50.

22. GugwadRS, Nagaral S. Effect of conventional and microwave curve on bond strength between denture base resin and acrylic teeth with different surface treatments. International Journal of Dental Clinics 2010;2:41-45.

|