Introduction

A detailed and dimensionally accurate impression is essential for the indirect fabrication of a fixed prosthesis[1]. An accurate impression results in precisely fitting cast restoration that determines the restoration’s longevity. Knowledge of impression materials and techniques to which each is best suited is required to achieve consistent good impression[2].

When using conventional impression techniques, the dentist makes two separate impressions in two trays- one of the prepared tooth and adjacent teeth and one of the opposing teeth. An occlusal registration is also needed. Moreover, if the dentist records the occlusal registration in a closed-mouth position and the impressions of the maxillary and mandibular arches in an open-mouth position, distortion and inaccuracy may result when the master casts are inserted into the occlusal registration. These three separate procedures require considerable chair time and materials and they introduce more opportunity for error[3].

Several impression techniques have been reported to improve the accuracy of impressions used in making fixed partial dentures. One such advancement is the introduction of dual-arch impression technique which was first reported by Getz in 1951, who used a water cooled tray with a reversible hydrocolloid. The credit for the introduction of this technique goes to Wilson and Werrin. Since then, the dual-arch impression technique has been in use in clinical practice[1].

Dual arch impression technique has many advantages over conventional impression procedure. In this technique, the impression of tooth preparations, adjacent teeth, opposing antagonistic teeth, all in their maximum intercuspation position and bite registration of relative opposing dentition can be captured simultaneously within a single impression tray[4].

Dual arch impression technique is time saving for both dentist and patient, reduces the chance of patient gagging, increases patient comfort and saves impression material. Castings produced by dual arch impression technique are highly accurate and require minimal adjustment at the time of delivery and makes mounting of casts similar to patient’s occlusion[4].

The present study is carried out to evaluate and compare the accuracy of metal and plastic dual arch impression trays.

Materials And Methods

For the present study, two metal dies of right mandibular first premolar and right mandibular first molar each was machined simulating the tooth preparation.

The first premolar metal die (Fig.1) had a chamfer margin and flat occlusal surface 3.35mm in diameter and 4.00mm in height from the chamfer margin to occlusal surfac. Crossgrooves were made on the occlusal surface for the measurement of buccolingual and mesiodistal dimensions.

| Fig. 1 – Premolar Metal Die

|

A groove was marked on the buccal surface of metal die for the measurement of occlusogingival dimension.

The first molar metal die (Fig.2) had a chamfer margin and flat occlusal surface 7.00mm in diameter and 3.86mm in height. On centre of the occlusal surface, a dot was made for the measurement of interabutment distance. The interabument distances from centre of right mandibular premolar to dot of right mandibular molar was 16.53 mm.

| Fig. 2 – Molar Metal Die

|

A metal base was attached to the base of the typhodont for stabilization and a metal block weighing 1.5 Kg was attached to the upper member of the typhodont so as to apply a uniform pressure while making impressions.

Right mandibular first premolar tooth was removed from the typhodont and right mandibular first premolar metal die was screwed in place to simulate a single die (Fig.3).

| Fig. 3 – Premolar Metal Die On Typhodont

|

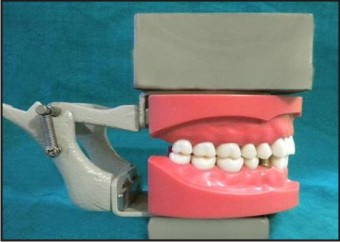

Group 1 - Fifty impressions were made using metal dual arch impression trays with polyvinylsiloxane impression material. A disposable interocclusal insert was used for this tray. Two step putty reline technique was used for making impression with putty and light body of polyvinylsiloxane impression material. The tray was seated onto the mandibular right quadrant and the articulator was closed until the unprepared teeth come in contact and there wasmaximum intercuspation on the left side (Fig. 4). Impression was poured by using improved dental stone and cast was allowed to set for 24 hours at room temperature.

| Fig. 4 – Impression Making With Metal Dual Arch Tray

|

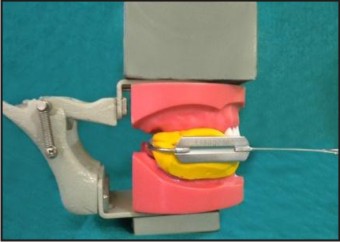

Group 2 - Fifty impressions were made with plastic dual arch impression trays by using the same technique and the materials (Fig. 5). as in group 1.

| Fig. 5 – Impression Making With Plastic Dual Arch Tray

|

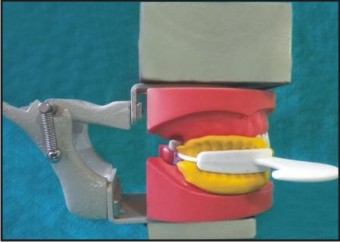

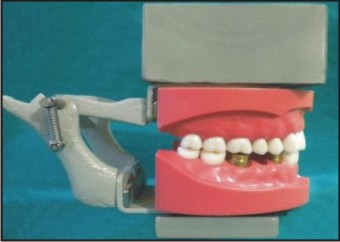

The typhodont was so modified to simulate a case for three unit fixed partial denture with right mandibular second premolar missing and right mandibular first premolar and right mandibular first molar as abutments. Then the right mandibular second premolar and right mandibular first molar teeth were removed from the typhodont and right mandibular first molar metal die was screwed in place on the typhodont (Fig.6).

| Fig. 6 - Premolar And Molar Metal Dies On Typhodont

|

Group 3 - Fifty impressions were made with metal dual arch impression trays by using the same technique and the materials as in Group 1.

Group 4 - Fifty impressions were made with plastic dual arch impression trays by using the same technique and the materials as in Group 1.

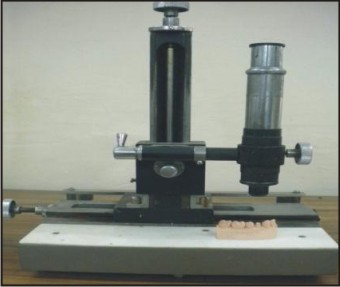

Buccolingual and mesiodistal dimensions of the first premolar metal die were measured from the grooves marked on the occlusal surface with a travelling microscope(Fig.7). Occlusogingival dimension was measured from the groove marked on the buccal surface with travelling microscope.

| Fig. 7 - Sample Testing Under Travelling Microscope

|

On the casts made with metal and plastic dual arch trays (Group 1 & 2), dimensions of premolar gypsum die were measured with travelling microscope from the same grooves as measured in metal die.

The interabutment distance of three unit fixed partial denture was measured from centre of the crossgrooves of premolar metal die to dot of molar metal die on typhodont with travelling microscope.

On the casts made with metal and plastic dual arch trays (Group 3 & 4), interabutment distance was measured with travelling microscope from the same points as measured on typhodont.

Results

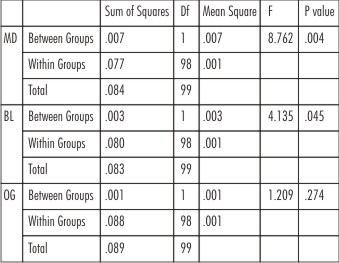

Results of one way ANOVA are presented in the Table 1 indicating that there was significant difference of mesiodistal and buccolingual dimensions between the metal and plastic tray (p<0.05). Difference of occlusogingival dimension between the metal and plastic tray was not significant (p>0.05).

| Table 1 : One-way Anova Results For Mesiodistal, Buccolingual And Occlusogingival Dimensions

|

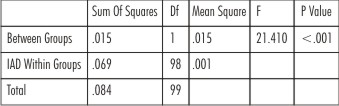

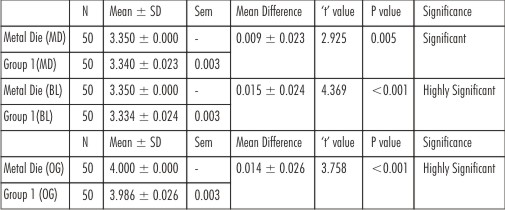

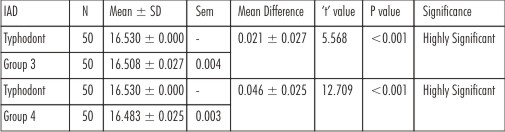

Results of one way ANOVA are presented in the Table 2 indicating that there was highly significant difference of interabutment distance between the metal and plastic tray (p<0.001). Table 3 shows that in group 1, there was significant difference of mesiodistal dimension (p < 0.05) and highly significant differences of buccolingual and dimension to that of the premolar metal die (p < 0.001).

| Table 2 : One-way Anova Results For Interabutment Distance

|

| Table 3

|

Table 4 shows that in Group 2, there was highly significant differences of mesiodistal, buccolingual and occlusogingival dimensions to that of the premolar metal die (p < 0.001).

| Table 4

|

Table 5 shows that There was highly significant difference between interabutment distance of group 3, group 4 and that on the typhodont (p < 0.001).

| Table 5

|

Discussion

The results of the present study showed that in group 1, mesiodistal dimension of gypsum dieis smaller than premolar metal die by 10µm, buccolingual dimension smaller by 16µm and occlusogingival dimension smaller by 14µm.

In group 2, mesiodistal dimension of gypsum dieis smaller than premolar metal die by 27µm, buccolingual dimension also smaller by 27 µm and occlusogingival dimension smaller by 21µm.

Results of the present study are in confirmity with the study done by Ceyhan JA et al[5]. Impressions were made of a circular stainless steel crown preparation using metal and plastic dual-arch impression trays and 3 dimensions (buccolingual, mesiodistal, and occlusogingival) of the dies were measured. Result concluded was same as in the present study that gypsum dies were smaller than stainless steel standard in all 3 dimensions.

Study done by Kang AH et al[6] is also in favour of the present study. Impressions were made of a removable stainless steel complete crown preparation using a dual-arch disposable plastic impression tray and same 3 dimensions (Buccolingual, mesiodistal, and occlusogingival) of the gypsum die were measured. The study concluded that single-step dual-arch impression technique produced working dies that were smaller than master die in all dimensions.

Results in the present study are not in confirmity of the study done by Breeding LC et al[7]. Impressions were made of a prepared tooth on a dentoform using plastic and metal dual-arch impression trays. The results indicated that plastic trays produced the dies larger than the tooth and metal trays produced dies smaller than tooth.

Interabutment distanceof Group 3 is smaller than that on typhodont by 22µm and of group 4 by 47µm.

Results in the present study are in confirmity with the study done by Reddy JM et al[1]. Impressions were made of prepared first premolar and first molar with second premolar removed to simulate a case for 3-unit fixed partial denture with full arch metal and plastic dual arch trays and full arch stock metal trays. The interabutment distance from the cast was measured and showed a decrease in interabutment distance with both metal and plastic dual arch impression trays.

The mean differences from mesiodistal dimension of premolar metal die are 10µm (Group 1) and 27µm (Group 2), from buccolingual dimension of premolar metal die are 16µm (Group 1) and 27µm (Group 2) and from occlusogingival dimension of premolar metal die are 14µm (Group 1) and 21µm (Group 2).

The mean differences from interabutment distance on the typhodont are 22µm (Group 3) and 47µm (Group 4).

Results of present study showed that metal dual arch trays are more superior regarding the dimensional accuracy than the plastic dual arch impression trays.

Results of the present study are in confirmity with the study done by Reddy JM et al[1]. Interabutment distance was measured on the cast made from metal and plastic dual arch impression trays and concluded that metal dual arch trays showed better accuracy in comparison to plastic dual arch trays.

The study done by Cox JR et al[8] also in the favour of present study. Impressions were made of cast metal copings cemented onto natural teeth prepared as complete-crown abutments using metal or plastic double arch trays and custom acrylic trays. Buccolingual and interabutment dimensions were measured and concluded that the plastic double-arch tray loaded with heavy-viscosity addition silicone and a low-viscosity wash produced the least accurate combination inter- and intra-abutment dimensions.

In another similar study done by Balkenhol M et al[9], impressions were made of four conical, standardized master abutments fixed on a metal plate using metal and plastic dual arch impression trays. The diameters of each of the four stone abutments was measured and concluded that the use of metal trays is superior regarding the dimensional accuracy and reliability of impression taking than the plastic trays.

The study done by Cehyan JA et al[10] is not in favour of the present study. Impressions of a customized abutment were made with metal dual arch, plastic dual arch and complete arch custom trays and 3 dimensions of the gypsum die (mesiodistal, buccolingual and occlusogingival) were measured. It was concluded that working dies from a plastic dual arch tray were more accurate buccolingually than those with metal dual arch trays.

Study done by Wostmann B et al[11] is not in favour of the present study. Impressions of a stainless steel cast with a partial crown, mod-inlay and full crown preparation were made using

metal, plastic dual arch trays and conventional trays. It was concluded that less rigid dual arch trays performed better than rigid ones.

Conclusion

Within the limitations of this study, the following conclusions were drawn:

Buccolingual, mesiodistal and occlusogingival dimensions and interabutment distance on the cast made with metal and plastic dual arch trays were smaller than that of metal dies on the typhodont.Metal dual arch trays wasbetter in dimensional accuracy than the plastic dual arch trays.

References

1. Reddy JM, Prashanti E, Kumar GV, Sajjan MCS, Mathew X. A comparative study of interabutment distance of dies made from full arch dual arch impression trays with those made from full arch stock trays: An in vitro study. Indian J Dent Res 2009; 20(4): 412-417.

2. Cox JR.A clinical study comparing marginal and occlusal accuracy of crowns fabricated from double-arch and complete-arch impressions. Australian Dental Journal 2005; 50(2): 90-94.

3. Kaplowitz GJ. Trouble shooting – Dual arch impressions. JADA 1996; 127(2): 234-240.

4. Kaplowitz GJ. Trouble shooting dual arch impressions – II. JADA 1997; 128(9): 1277-1281.

5. Ceyhan JA, Johnson GH, Lepe X. The effect of tray selection, viscosity of impression material and sequence of the pour on the accuracy of dies made from dual arch impressions. J Prosthet Dent 2003; 90(2): 143-149.

6. Kang AH, Johnson GH, Lepe X, Wataha JC. Accuracy of a reformulated fast set vinyl polysiloxane impression material using dual arch trays. J Prosthet Dent 2009; 101(5): 332-341.

7. Breeding LC, Dixon DL. Accuracy of casts generated from dual-arch impressions. J Prosthet Dent 2000; 84(4): 403-7.

8. Cox JR, Brandt RL, Hughes HJ. A clinical pilot study of the dimensional accuracy of double-arch and complete-arch impressions. J Prosthet Dent 2002; 87(5): 510-5.

9. Balkenhol M, Ferger P, Wostmann B. Dimensional accuracy of 2- Stage putty wash impressions: Influence of impression trays and viscosity. Int J Prosthodont 2007; 20(6): 573-575.

10. Ceyhan JA, Johnson GH, Lepe X, Phillips KM. A clinical study comparing the three-dimensional accuracy of a working die generated from two dual arch trays and a complete arch custom tray. J Prosthet Dent 2003; 90(3): 228-234.

11. Wostmann B, Rehmann P, Balkenhol M. Accuracy of impressions obtained with dual arch trays. Int J Prosthodont 2009; 22(2): 158-60.

|