Introduction:

The fabrication of provisional crown in a fixed partial denture case is a necessary procedure following extra coronal tooth preparation[1]. Pulpal injury during fabrication of provisional crowns may result from heat produced from polymerization of resins, desiccation or chemical insult from the monomer. The exothermic reaction that occurs during setting of autopolymerizing resins can coagulate the protoplasm and the chemicals may coagulate or dissolve it. If a significant amount of heat is transferred to the tooth structure, odontoblastic and pulpal changes may occur[2]. Histological studies have reported that an intra pulpal temperature rise of 5.5oC can lead to 15% loss of vitality of the pulp; an 11oC temperature rise causes about 60% and 16.60C temperature rise can cause 100% necrosis of the pulp.[3], [4].

Teeth that are prepared for restorations especially crowns, are at risk of developing hypersensitivity because a large number of dentinal tubules are exposed during preparation[5]. Approximately 1-2 million dentinal tubules are exposed during an average tooth preparation for a posterior crown[5]. The effect of curing resinous crown in different matrices, such as polyvinylsiloxane impression and vacuum formed polypropylene sheet has also been evaluated. The results demonstrated that the amount of heat generated during polymerization can cause damage to odontoblasts and pulp[1],[6]. Provisional restorations are prepared by different methods like direct method (in the patient's mouth), indirect method and indirect- direct combination of both. Each method has its own advantages and disadvantages. Several types of acrylic resin materials are available for interim restorative treatment[4],[7] as Polymethylmethacrylate (PMMA) Polyethylmethacrylate (PEMA) combinations of unfilled methylmethacrylate acrylic resins and bis- acryl composites.

Temperature changes from the exothermic reaction of the polymer based provisional restorative materials have shown that if the temperature increase exceeds the physiologic heat dissipation mechanism of the dental- periodontal systems; then damage could occur, especially to the pulp. In both the techniques of fabrication of provisional restorations, a matrix is used to carry the restoration material to the prepared tooth. Different matrix materials used to carry provisional restorative material in direct technique are vacuum formed templates, polyvinylsiloxane putty and alginate matrix etc[7],[8].

The purpose of this study was to compare the heat transferred to the pulp by different types of resins and most commonly used matrices ie. alginate and polyvinylsiloxane for fabricating direct extracoronal provisional restorations.

MATERIALS AND METHOD

Preparation of the die

A freshly extracted mandibular molar with intact enamel and dentine structure was taken for the purpose of the study. The tooth was without any carious lesion or fillings. Root portion was sectioned with a carborundum disc approximately 4 mm below the cementoenamel junction (CEJ) perpendicular to the long axis of the tooth[9].

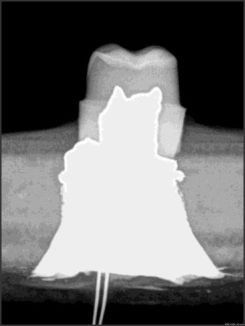

An opening was made into the pulp chamber with round diamond bur (no801.14) from the radicular portion of the tooth to insert a thermocouple. Remnants of pulp tissue were cleaned with small spoon excavator and cotton pellets. The pulp chamber was then cleansed of all organic remnants by irrigating with 5.25% sodium hypochlorite solution and distilled water[10]. The tooth was stabilized in acrylic resin block. (Fig.1)

| Figure 1: Acrylic model with tooth

|

Biomechanical preparation of the natural tooth with 1.5mm shoulder and 2mm occlusal clearance was done (Fig.2) and casting was obtained using lost wax technique. It was mounted on another resin block of the same dimension.(Fig.3) A thermocouple probe (4-foot type K thermocouple bead probe Teflon tape insulated) connected to a digital precision thermometer (MODEL 305 digital thermometer) was placed through the root canal into the pulp chamber touching the roof of the chamber. (Fig.4, 6) A radiograph was taken to ensure that the thermocouple was in contact with the overlying dentine. (Fig.5)

| Figure 2: Prepared molar

|

| Figure 3: Acrylic model with metal analog

|

| Figure 4: Prepared molar with thermocouple

|

| Figure 6: Prepared molar with thermocouple with digital thermometer

|

| Figure 5: IOPA showing thermocouple probe within pulp chamber

|

Silver amalgam (DPI Alloy) restorative material was condensed into the pulp chamber surrounding and stabilizing the thermal probe in position. Afterwards, the acrylic resin was placed over the apical opening. Amalgam condensation around the thermal probe (4-foot type K thermocouple bead probe Teflon tape insulated) permitted collection of reading from all directions, as amalgam is a good conductor. A final radiograph was taken to ensure that the thermocouple was in contact with the overlying dentin.

A thin layer of petroleum lubricant (Vaseline) was applied to the acrylic resin block and the prepared tooth. The assembly was then placed in a water bath containing distilled water at a temperature of 370C to thermally equilibrate[6]. The water bath was used to simulate intraoral conditions.

Preparation of the matrices

Study was divided into two groups on the basis of matrix used. (Fig.7) Group 1 comprised Irreversible hydrocolloid (Marieflex, Septodont Healthcare India Pvt. Ltd.) material which was mixed according to the manufacturer's directions, loaded in a perforated custom tray and adapted over the metal duplicate of the mounted tooth. The impression was covered with moist gauze piece to prevent drying of the matrix. For every sample, a new irreversible hydrocolloid (Marieflex) matrix was made.

| Figure 7: Material used in study

|

Group 2 comprised polyvinylsiloxane putty (Express TM XT Putty Soft, 3M-ESPE ) impression material which was mixed according to the manufacturer's directions and loaded in a perforated custom tray and adapted over the metal duplicate of the mounted tooth, thus creating a putty matrix. (Table 1)

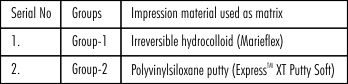

| Table 1

|

Preparation of provisional restorations

Two types of provisional resins were used in this study- Polymethylmethacry late resins and Bis-acryl composite resins.(Fig.8) Two of the most commonly used and commercially available brands were selected for each resin material. These were divided into four subgroups according to the restoration material used. These were divided as

Subgroup A: Acry-Lux crown & bridge material (Ruthinium Dental Products Pvt. Ltd.) PMMA resin

Subgroup B: DPI tooth moulding crown & bridge materials (DPI).

Subgroup C: Protemp TM 4(3M ESPE) Bis-acryl composite resin

Subgroup D: Cooltemp (Coltene Whaledent) Bis-acryl composite resin. (Table 2)

I. Preparation of provisional restoration with Acry-Lux provisional crown & bridge material and DPI tooth moulding crown & bridge material (polymethylmethacrylate).

| Figure 8: Impression material as matrix with provisional crown material and crowns

|

| Table 2

|

Powder and liquid were mixed according to manufacturer's instructions in a dappen dish. The prepared tooth assembly was brought to a constant initial temperature of 370C to thermally equilibrate by placing it in water bath [Serological water bath (Navyog India)] [6]. Once intrapulpal temperature was stabilized, the assembly was recovered. The Acry-Lux provisional restoration material in dough stage was loaded in the Irreversible hydrocolloid (Marieflex) matrix and then placed over the prepared tooth for making the provisional restoration. Temperature was recorded by using the digital thermometer during polymerization at 30 seconds intervals until no further increase in temperature was noted. After complete polymerization, the matrix and Acry-Lux crown & bridge provisional restoration was removed from the tooth assembly. Same procedure was performed to prepare provisional restorations with DPI tooth moulding crown & bridge material. Similar procedure was performed using polyvinylsiloxane (Express TM XT Putty Soft) putty matrix for preparation of provisional restoration with Acry-Lux provisional crown & bridge material and DPI tooth moulding crown & bridge material.

II. Preparation of provisional restoration with ProtempTM4 provisional crown & bridge material and Cooltemp (Bis-Acryl Composite Resin).

ProtempTM4 provisional restoration material was mixed according to manufacturer's instructions. The remaining procedure is same as that of the above mentioned material. Same procedure was performed to prepare provisional restorations with Cooltemp.

Observation and Results

A comparative study consisting of two main groups (of matrix material) further divided into four subgroups (of provisional resin material) was undertaken to find the group with which maximum temperature change was attained during the fabrication of provisional restorative crowns with different matrix materials.

The mean temperatures rise recorded are given below:

Group 1A: 2.090C, Group-1B: 2.290C, Group-1C: 1.130C, Group-1D: 1.250C, Group-2A: 4.220C, Group-2B: 4.630C, Group-2C: 2.020C & Group-2D: 2.190C.

Statistical Methods

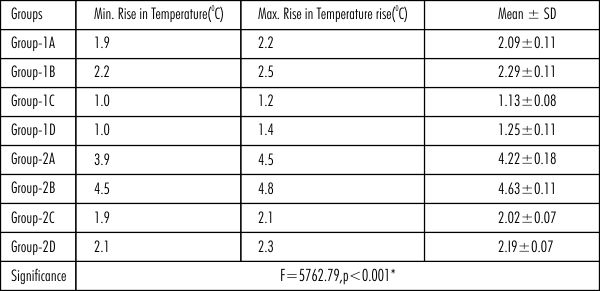

Analysis of variance (ANOVA) & student t-test has been used in this study to find the significant difference of the amount of temperature attained during the study period between the four groups. (Table 3) Where F indicates, Fischer value and p indicates probability value. The Post-hoc Tukey test was used to find the pair-wise significance of temperature rise between the eight sub groups.

| Table 3 Rise in temperature (0C) during temporization in groups.

|

Table 4 shows pair wise comparative analysis of rise in temperature during temporization among the Group-1 Irreversible hydrocolloid (Marieflex) impression material as matrix and Group-2 (Express TM XT Putty Soft) impression material as matrix. The results show that there is no significant difference (rise in temperature) between Group-1A, Group-2C and Group-2D; also there was no significant difference (rise in temperature) between Group-1B and Group-2D. There was no significant difference (rise in temperature) between Group-2D, Group-1A and Group-1B.

| Table 4 Pair wise comparison between groups (Group-1A, Group-1B, Group-1Cand, Group-1D Group-2A, Group-2B, Group- 2C and Group-2D).

|

It is concluded from the study that the Marieflex impression material as matrix with ProtempTM4 showed least increase in the rise of temperature during temporization. The mean temperature recorded in this group was 1.130C which was close to the value noted with the Cooltemp where mean rise in temperature was 1.25oC. In the Express TM XT Putty Soft impression material group with DPI tooth moulding (polymethylmethacrylate) showed the highest increase in the intra pulpal temperature (4.630C) as compared to other groups. Minimum temperature rise in the polyvinylsiloxane matrix was seen with Protemp provisional material (2.09oC) which was close to that of Cooltemp (2.19OC). In the polyvinylsiloxane (Express TM XT Putty Soft) impression material as matrix with ProtempTM4 group, the mean rise in temperature recorded was 2.020C.

Discussion

There is a need to find a suitable method that can decrease exothermic heat transferred to the pulp during fabrication of provisional restoration using direct technique. Factors that influence the heat transfer to pulp are thickness of dentine, type of resin used, quantity of resin used and type of matrix used.

Matrix is required to transfer the provisional restoration material to the tooth in both direct and indirect methods as it absorbs heat to some extent. The heat transferred to the tooth is influenced by the choice of matrix to hold the provisional restoration material[1]. This heat release could be because of the addition polymerization reaction where heat is emitted during setting of the polymer-based provisional materials. Increase concentration of accelerator and also the type of accelerator also affects the temperature rise.

An in-vivo study conducted by Zach and Cohen[3] in the year 1965 showed that intra pulpal temperature rise of 5.50C in Rhesus monkey caused 15% loss of pulp vitality and the thermal damages included various histopathological changes in the pulp such as destruction of odontoblasts, cellular degeneration, burn reaction at periphery of the pulp including formation of blisters, coagulation of protoplasm, expansion of liquid in dentinal tubules and vascular injuries with generalized or localized tissue necrosis resulting in acute inflammation of pulp[3].

The values for temperature rise obtained in this study indicate that the pulp could be subjected to an iatrogenic insult with any combination of matrix and provisional restoration material used. The combination which showed minimum temperature rise was alginate with Protemp. It is important to remember that the tooth was ideally prepared, and thus the values obtained were minimal. Over reduction or presence of metallic restoration would tend to magnify the thermal insult. Greater temperature variation was seen with change of matrix i.e. (alginate) than with change of resin material.

There are limitations in the present study as it was conducted in in-vitro conditions. Further studies may be conducted using in-vivo conditions. Also in this study, provisional for single crown was studied. In oral cavity, temperature rise can be reduced by presence of periodontal ligament and dentinal tubules. Also cooling technique like water spray can be employed and provisional crown should be removed after initial polymerization and then placed again after cooling the tooth with water.

Direct provisional crown fabrication technique is preferable for a single unit or short span bridge or endodontically treated teeth. Most commonly employed technique employed for long span bridge should be indirect technique.

Indirect provisional crown fabrication methods should be preferred as they avoid thermal insult to the prepared teeth. When due to unavoidable reasons, direct fabrication of restoration has to be performed to save time then a technique using that matrix- resin material combination should be preferred which causes minimum rise in temperature.

Conclusion

An in-vitro study was conducted to evaluate the temperature rise in the pulpal chamber during fabrication of provisional crowns with two different impression materials as matrix and four different provisional crown materials involving direct technique.

The intra pulpal rise in temperature during temporization from greatest to least, based on the provisional crown material used in the study was Polymethylmethacrylate (DPI Tooth molding crown & bridge material and Acry-Lux crown & bridge material) > Bis-acryl composite resin (ProtempTM4 and Cool Temp). Intra pulpal rise in temperature during temporization is greatest when Polyvinylsiloxane putty (Express TM XT Putty Soft) impression material was used as the matrix material, whereas Irreversible hydrocolloid (Marieflex) impression material showed least intra pulpal rise in temperature when used as matrix material. Combination of Alginate matrix with bis-acryl composite shows least rise in temperature. Fabricating provisional crowns by direct technique using polyvinylsiloxane (Express TM XT Putty Soft) impression material as matrix with Polymethylmethacrylate as provisional crown shows maximum rise in pulpal temperature during temporizations which could affect the vitality of pulp.

References

1. Moulding MB, Teplitsky PE. Intrapulpal temperature during direct fabrication of provisional restorations. Int J Prosthodont1990; 3:299-304.

2. Nyborg H, Brännström M. Pulp reaction to heat. J Prosthet Dent 1968; 19:605-12.

3. Zach L, Cohen G. Pulp response to externally applied heat. Oral Surg Oral Med Oral Pathol 1965;19:515-30.

4. Burns DR, Beck DA, Nelson SK; Committee on Research in Fixed Prosthodontics of the Academy of Fixed Prosthodontics. A review of selected dental literature on contemporary provisional fixed prosthodontics treatment: report of the Committee of Research in Fixed Prosthodontics of Academy of Fixed Prosthodontics. J Prosthet Dent 2003; 90:474-97.

5. Ha JY, Kim SH, Kim KH, Kwon TY. Influence of the volumes of bis-acryl and poly(methyl methacrylate) resins on their exothermic behavior during polymerization. Dent Mater J. 2011;3:336-42.

6. Castelnuovo J, Tjan AHL. Temperature rise in pulpal chamber during fabrication of provisional resinous crowns. J Prosthet Dent 1997;78:441-6.

7. Moulding MB, Loney RW. The effects of cooling techniques on intrapulpal temperature during direct fabrication of provisional restorations. Int J Prosthodont 1991;4:332-6.

8. Hanning M, Bott B. In vitro pulp chamber rise during composite resin polymerization with various light curing sources. Dent Mater 1999; 15:275-81.

9. Goodis HE, White JM, Andrew J, Watanabe LG. Measurement of temperature generated by visible light-cure lamps in an in vitro model. Dent Mater 1989; 5:230-4.

10. Michalakis K, Pissiotis A, Hirayama H, Kang K, Kafantaris N. Comparison of temperature increase in the pulp chamber during polymerization of materials used for the direct fabrication of provisional restorations. J Prosthet Dent 2006; 96:418-23

11. Chang SW, Lee SI, Bae WJ, Min KS, Shin ES, Oh GS, Pae HO, Kim EC.Heat stress activates interleukin-8 and the antioxidant system via Nrf2 pathways in human dental pulp cells. J Endod 2009; 35:1222-8.

|