Introduction

In today's world of high stress patients have become more demanding in terms of esthetic and comfort treatment. They seek more and more esthetic and painless treatment modalities. Keeping this in mind, provisional restorations play an important role in providing the necessary and required interim treatment options.

Provisional restoration is a fixed or removable dental prosthesis, designed to enhance esthetic stabilization and/or function for a limited period of time, after which it is to be replaced by a definitive dental prosthesis. Often such prosthesis are used to assist in determination of the therapeutic effectiveness of a specific treatment plan or the form and function of the planned definitive prosthesis.1,2

Provisional restorations must protect the prepared tooth surface from various thermal and chemical stimuli present in the oral environment to prevent sensitivity and further irritation to the pulp. It must have good marginal fit, proper contour, a smooth surface for good periodontal health and easy to manipulate. To serve these functions a provisional restorative material must be strong enough to resist masticatory forces, especially in long span restorations or areas of heavy occlusal stress.2

In the clinical situation, a fixed partial denture is subjected to variety of forces during function. These forces have been shown by three point bent test which analyzes the stresses as, compressive at the point of application of load, and tensile and shear at the points of resistance to that load.

The objective of this present study was to evaluate and compare the flexural strength of four commercially available provisional materials to find out which material possesses the better flexural strength, and can be used successfully in long span bridges.

Materials And Methods

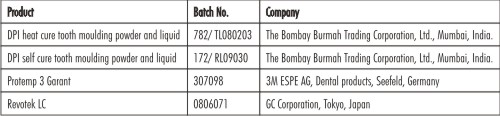

The four different types of commercially available provisional restorative materials chosen for this study were, tooth coloured heat cure acrylic resin (DPI heat cured tooth moulding powder/liquid), tooth coloured auto-polymerized acrylic resin (DPI self cured tooth moulding powder/liquid), auto-polymerized composite resin (Protemp 3 Garant) and light cured composite resin (Revotek LC) (Table 1). Fifteen specimens of each test material were fabricated using a standardized brass mould measuring 26mm in length, 10mm in width and 2mm in thickness.

| Table 1 – Test materials used in the study

|

Sixty Aquasil putty impressions were made of the brass mould (Fig.1). Molten Hiflex modelling wax was filled in putty impressions to make wax patterns. After wax hardened, the wax patterns were retrieved. Fifteen wax patterns were invested in a Hanau flask for fabricating heat cured acrylic resin specimens using standard compression moulding technique and a short curing cycle (Fig.2).

| Fig.1. Putty impressions made with brass mould

|

| Fig.2. Wax patterns invested in a Hanau flask

|

Fifteen auto-polymerized acrylic resin specimens were also fabricated by compression moulding technique and polymerized under 32 psi pressures at 370C for 10 minutes in pressure pot (Polyclav). Fifteen auto polymerized composite resin specimens were prepared with the help of auto mixing device. Auto-polymerized composite resin was poured into mould and smoothened with the help of cellophane sheet. The specimen was removed after 2 min 30 sec as recommended by the manufacturer. Fifteen auto-polymerized light cure composite resin specimens were prepared by removing the material from tube with plastic spatula. The material was pressed into the putty impressions and smoothened with the cellophane sheet. The specimens were placed in light cure unit and cured for 90 seconds.

All these specimens were finished with a carbide bur and 600 grit silicon carbide papers, and checked by a Vernier calliper for accurate dimensions (Fig.3). All specimens were immersed in normal saline for 24 hours and thereafter, tested for flexural strength on Instron universal testing machine with a cross head speed of 1.25 mm/min speed (Fig.4).

| Fig.3. Specimens checked by Vernier Caliper

|

| Fig.4. Specimens tested on Instron universal testing machine

|

Results

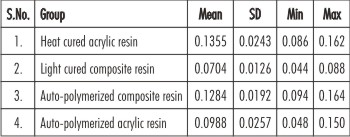

Result showed that the highest mean flexural strength was found in Heat Cured acrylic resin group, while light cured composite resin group exhibited the lowest mean flexural strength (Table 2).

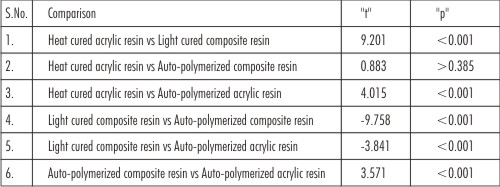

Analysis of variance of flexural strength in different groups showed F value to be 29.969 which was highly significant (p<0.001) (Table 3). In intergroup comparisons, student's t test was performed. Auto-polymerized composite resin showed significantly higher mean flexural strength as compared to auto-polymerized cold cure acrylic resin and light cured composite resin (p<0.001). Difference between Heat cured acrylic resin and auto-polymerized composite resin groups was not statistically significant (p>0.385). On comparison with auto-polymerized cold cured acrylic resin and Heat Cure acrylic resin, light cured composite resin showed lower mean flexural strength values, which was highly significant (p<0.001). Mean flexural strength of auto-polymerized cold cure resin group was significantly lower than the Heat Cured acrylic resin group (p<0.001) (Table 4).

| Table 2 - Intergroup comparison of mean strength (kN)

|

| Table 3 - Analysis of variance of strength in different groups

|

| Table 4 - Intergroup comparison using student t test

|

Discussion

In the present study, four tooth coloured, chemically different, commercially available crown and bridge provisional restorative materials were chosen to test and compare the flexural strength. Earlier, denture base materials3,4,5 were used for provisional restorative materials which were not esthetically pleasant. These were later replaced by tooth coloured methyl methacrylate base materials. Now more advanced provisional restorative materials are available e.g. Bis - GMA based material and urethane dimethacrylate material.3

The limitations of provisional restorations are lack of inherent strength, poor colour stability, and poor wear properties. To increase the strength and rigidity, various studies6,7 have been conducted. Some workers4,5,6,7,8 used different types of fibres reinforcement in heat cured methyl methacrylate and found that fibre reinforcement increases the flexural strength by many folds but these methods are very difficult and time consuming. Thus, researches have been carried out to modify the chain structure for enhancing the flexural strength of materials. Protemp 3 Garant is a Bis acrylic resin composite material, in which the manufacturer modified the chain structure of Bis acrylic resin composite materials to increase the flexural strength. Bis acrylic resin composite materials are difunctional and capable of cross linking with another monomer chain. This cross-linking imparts strength and toughness to the material.9 Protemp 3 Garant is based on these modifications in which instead of rigid intermediate chain characteristics of some Bis-acrylic homologues, it also has flexible chain in comparison to other synthetic resin. S. Dagar et al conducted a study on direct and indirect provisional materials and found that Protemp 2 has lesser flexural strength as compared to heat cure polymethyl methacrylate and self cure poly methyl methacrylate.10 In our study auto-polymaerized composite resin (Protemp 3 Garant) also showed less strength as compared to heat activated poly methyl methacrylate.

Provisional restoration should not be casually fabricated on the basis of expected short term use. In case of unforeseen events (e.g. Laboratory delays or Patient unavailability), a provisional restoration may have to function for a extended period of time.2 Auto-polymerized composite resin (Protemp 3 Garant) and heat cured acrylic resin can be used where we need provisional restoration for months or in long span bridges by direct method.

This is in - vitro study, further researches based on in-vivo and varying the thickness of specimens can be performed.

Conclusion

Within the limitations of this study, it may be concluded from that:-

1) Heat Cured acrylic resin showed maximum flexural strength among all the tested materials.

2) Light cured composite resin showed minimum flexural strength among all tested materials.

3) There was no statistically significant difference between heat cure acrylic resin and Auto-polymerized composite resin.

4) The sequence of mean flexural strength in decreasing order is as follows:- Heat cured acrylic resin ? Auto-polymerized composite resin > Auto-polymerized cold cured acrylic resin > Light cure composite resin.

References

1. The glossary of prosthodontic terms. J Prosthet Dent 2005;94:46.

2. Rosensteil SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. 3rd edition, The CV Mosby: St. Louis; 2001. 380-416.

3. Pfeiffer P, Rolleke C, Sherif L. Flexural strength and moduli of hypoallergenic denture base materials. J Prosthet Dent 2005; 93: 372-377.

4. Bertassoni LE, Marshall GW, Souza EM, Rached R N. Effect of pre and postpolymerization on flexural strength and elastic modulus of impregnated, fiber reinforced denture base acrylic resins. J Prosthet Dent 2008; 100: 449-457.

5. Dagar SR, Pakhan AJ, Thombare RU, Motwani BK. The evaluation of flexural strength and impact strength of heat polymerized polymethyl methacrylate denture base resin reinforced with glass and nylon fibers. J Indian Prosthod Soc 2008; 8: 98-104.

6. Vallitu PK. Flexural properties of acrylic resin polymers reinforced with unidirectional and woven glass fibers. J Prosthet Dent 1999; 81: 318-326.

7. Kanie T, Fujii K, Arikawa H, Inoue K. Flexural properties and impact strength of denture base polymer reinforced with woven glass fibers. Dent Mater 2000; 16: 150-158.

8. John J, Gangadhar SA, Shah I. Flexural strength of heat polymerized polymethyl methacrylate denture resin reinforced with glass, aramid or nylon fibers. J Prosthet Dent 2001; 86: 424-427.

9. Ellakwa A E, Shortall A C, Marquis P M. Influence of fiber type and wetting agent on the flexural properties of an indirect fiber reinforced composite. J Prosthet Dent 2002; 88: 485-490.

10. Dagar S,Pakhan A, Tunkiwala A. An in vitro evaluation of flexural strength of direct and indirect provisionalization materials. J Indian Prosthod Soc 2005; 5: 132-135. |