Introduction:

The introduction and use of acrylic resin as a denture base material since 1937 has revolutionized the dentistry in a big way. The resin has fine esthetic properties, excellent in color and chemically stable. It can be used with a simple technique for the construction of dentures, but the properties of acrylic resin are not ideal in all aspects. Knowledge of chemistry, physical properties, qualities, characteristics, and manipulative procedure are therefore imperative if reasonably satisfactory results have to be obtained from the use of the material. Dimensional changes which occur in heat cure acrylic resins are shrinkage and expansion which affects the fit of the denture and occlusal relationship11. Precise duplication of trial denture into the final prosthesis is the desired aim during processing in the laboratory. However, certain properties like dimensional inaccuracies of the materials compromise the attainment of this goal optimally. Different authors compared various resins to denture rubber by examining certain physical and mechanical properties of different materials3, 4, 8, 10.

Considering the importance of dimensional changes occurring during processing, the present study was undertaken to determine linear dimensional changes of four commercially available heat cure acrylic resins.

AIM AND OBJECTIVES

The present study was designed with the following aim and objectives:

1. To study the linear dimensional changes of four different brands of heat cure acrylic resins before and after curing.

2. To compare the linear dimensional changes of heat cure acrylic resin among the four different acrylic brands.

MATERIAL AND METHODS:

The study was carried on twenty four edentulous subjects, irrespective of age and sex selected from the department of Prosthodontics including Crown and Bridge, M.M. College of Dental Sciences & Research, Mullana. Thorough diagnosis and case history was recorded for each subject. For each subject four mandibular complete dentures were fabricated using four different brands of heat cure acrylic resins.

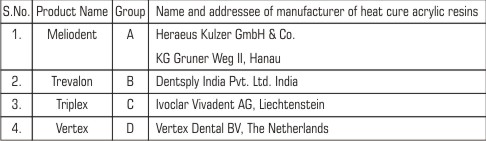

Four different brands of heat cure acrylic resins were used in this study (Fig 1).

| Fig 1. Four different heat cure materials used

|

|

|

The brand name and manufacturer’s name of heat cure acrylic resins used for the study were as follows and they were grouped from Group A to group D as under:

Complete dentures were fabricated for each subject in conventional manner. For each subject four additional edentulous mandibular casts were duplicated to fabricate four experimental dentures one each from the four different acrylic resin used in the study. Therefore, the edentulous mandibular master cast was duplicated and four additional casts were made for each subject using reversible hydrocolloid agar material. The master cast which was used for the duplication, was used to fabricate patient’s denture which was delivered to the patient at the end of the treatment. Finally, four mandibular casts for each individual subject were obtained. Following the same procedure for remaining twenty-three subjects a total of ninety six

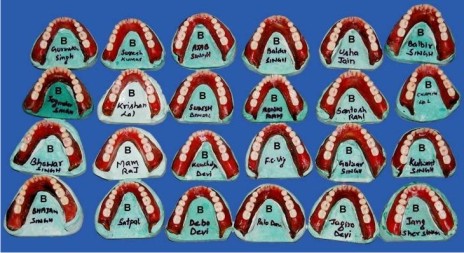

casts were obtained. On the casts so obtained ninety six experimental mandibular dentures were fabricated. The teeth set chosen for the study had same mold. After the teeth arrangement, three stainless steel pins were fixed in mandibular denture with the help of autopolymerizing resin. Out of three pins, two pins were fixed in central fossae of first molar on both sides and one pin in the cingulum of left central incisor so that three measurements between pins can be obtained. The dentures were fabricated using standard amount of powder liquid ratio of 3:1 and curing the dentures under standardized conditions and opting for a standard routine for polishing (Fig 2).

| Fig 2. 24 Dentures of one group after fabrication

|

The tip of the stainless steel pin was marked with blue color and the marks were transferred onto the paper and the measurements were taken with the help of digital vernier caliper (Fig 3 and 4) between two points i.e. molar to molar and molar to central incisor.

| Fig 3. Digital Vernier Caliper

|

| Fig 4. Measurement of marks after transferring to paper.

|

Measurements were made between molar pins and central incisor pin.

1. AB - Left central incisor to right molar.

2. BC - Right molar to left molar.

3. CA - Left molar to left central incisor.

The readings between these points were made thrice for each of the dentures. The mean of three readings was taken as a single reading to reduce the error. The measurements were taken at three different stages, first after the wax up and carving

of trial mandibular denture, second after curing and final reading after finishing and polishing of dentures.

TO EVALUATE THE LINEAR DIMENSIONAL CHANGES

So finally three types of readings were taken for each of the processed dentures and same procedure was repeated for remaining ninety five experimental dentures.

The difference between pre-cured and cured experimental dentures were analyzed,

The difference between pre-cured and after finishing and polishing were analyzed,

The difference between cured and after finishing and polishing were also analyzed,

RESULTS:

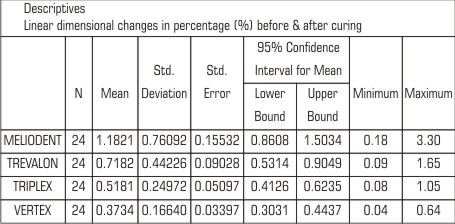

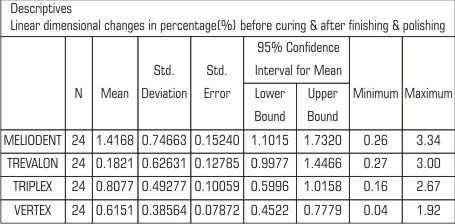

Table 1 shows the difference in the linear dimensional changes before and after curing among the groups. The maximum percentage changes were seen in cases of Group-A (Meliodent) followed by Group-B, Group-C and Group-D (Trevalon, Triplex and Vertex). Out of all the ninety six experimental mandibular dentures corresponding to twenty four subjects, the experimental dentures cured with Group-A (Meliodent) showed the highest percentage change i.e. 1.18%. The dentures fabricated with Group-D (Vertex) showed the percentage change of 0.37% which was the least when compared between all the four heat cure acrylic resins. Group-B and Group-C (Trevalon and Triplex) showed in between the percentage values of Group-A and Group-D (Meliodent and Vertex) but in between the two, Group-B (Trevalon) had higher percentage value (0.71%) when compared to Group-C (Triplex- 0.51%). Linear dimensional changes in all groups are shown in Table No 1.

| Linear dimensional changes before and after curing:

TABLE 1 - Linear dimensional changes in percentage before and after curing.

|

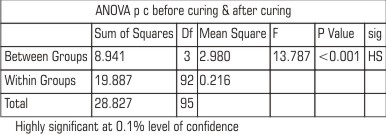

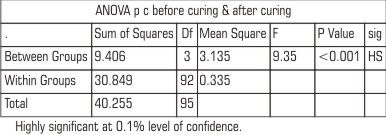

Table 2 shows the statistical comparison between before curing and after curing and demonstrates that the results are highly significant at 0.1% level of confidence i.e. shows considerable difference between before curing and after curing.

| Table 2 - Statistical comparison of linear dimensional changes in percentage before and after curing:

|

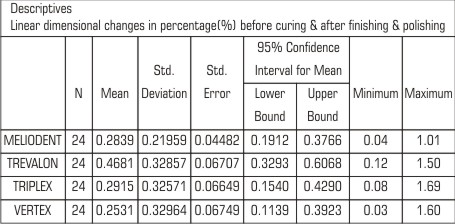

Table 3 shows the difference in the linear dimensional changes before curing and after finishing and polishing. The maximum percentage changes were seen in cases of Group-A (Meliodent) followed by Group-B, Group-C and Group-D (Trevalon, Triplex and Vertex) respectively. Out of all ninety six mandibular dentures corresponding to twenty four subjects, the dentures cured with Group-A (Meliodent) showed the highest percentage value of 1.42%. The dentures fabricated with Group-D (Vertex) showed the percent mean value of 0.62% which was the least when compared between all the four heat cure acrylic resins. Group B and Group C (Trevalon and Triplex) heat cured mandibular experimental dentures showed in between the percentage values of Group-A and Group-D (Meliodent and Vertex), but in between the two also Group-B (Trevalon) had higher percentage value (1.18%) when compared to Group-C (Triplex-0.81%).

| Linear dimensional changes before curing and after finishing and polishing:

TABLE 3 - Linear Dimensional Changes in Percentage Before curing and After Finishing & Polishing

|

Table 4 shows the statistical comparison between before curing and after finishing and polishing and demonstrates that the results are highly significant at 0.1% level of confidence i.e. show considerable difference between before curing and after finishing and polishing.

| Table 4 - Statistical comparison linear dimensional changes in percentage before curing and after finishing & polishing

|

Table 5 and shows the difference in the linear dimensional changes after curing and after finishing and polishing. The maximum percentage changes were seen in cases of Group-B (Trevalon), followed by Group-C, Group-A and Group-D (Triplex, Meliodent and Vertex). Out of all ninety six mandibular dentures corresponding to twenty four subjects, the experimental dentures cured and finished with Group-B (Trevalon heat cured acrylic resin) showed the highest percentage value i.e. 0.46%. The denture constructed with Group-D (Vertex heat cure acrylic resin) showed percentage value of 0.25%, which were the least when compared between all the four groups of heat cure acrylic resins. Group-C and Group-A (Triplex and Meliodent heat cured mandibular dentures) showed in between the percentage values of Group-B and Group-D (Trevalon and Vertex), but in between the two, Group-C (Triplex) had higher percentage value (0.29%) when compared to Group-A (Meliodent-0.28%).

| Linear dimensional changes after curing and after finishing and polishing:

TABLE 5 - Linear dimensional changes in percentage after curing and after finishing & polishing

|

Table 6 shows the statistical comparison between after curing and after finishing and polishing and demonstrates that the results are significant at 0.1% level of confidence i.e. show difference between after curing and after finishing and polishing.

| TABLE 6 β Statistical comparison linear dimensional changes in percentage after curing and after finishing & polishing

|

DISCUSSION:

The acrylic resin has been very successful as a denture base, as it has fine esthetic properties, excellent color stability and can be used with a simple technique for the construction of dentures. Inspite of having all these advantages, lack of dimensional stability is widely accepted as one of the disadvantages of acrylic resin dentures.

In the processing of dentures, a portion of stress produced in the plastics as they cool below this temperature is relieved when the dentures are separated from the casts, and the amount of shrinkage which occurs is proportional to the range of cooling below the second order transition temperature 1. Komiyama and Kawara6 stated that the stress produced by thermal contraction is relieved shortly after the denture has been removed from the mold and that stress, caused by polymerization contraction, will be relieved more gradually. They concluded that the thermal contraction stresses are of instantaneous mechanical nature, where as the stresses caused by polymerization are on a molecular level involving polymer chains. Zissis, Huggert, Harrison12 embedded steel pins in the wax trial bases and measured distance from the outside of one pin to the outside of the other, with the help of vernier caliper having accuracy 0.001inch before and after curing.

Woelfel10 stated a method of linear measurements on each denture (molar-to-molar) was made at various times at 22 ±10C. (72 ± 20F) with a toolmaker’s microscope and were recorded to the nearest 0.0025mm. (0.0001inch). The reference marks were fine cross lines ruled on polished stainless steel pins cemented in the second molars. Posterior linear measurements instead of contour measurements were made, as shown that linear changes occurring in across the posterior portion of a denture are of significantly greater magnitude than in any other area. Also the changes occurring in the posterior region are the most important in the retention of denture because of the anatomy of the mouth and the shape of the denture. He demonstrated a very small dimensional shrinkage (0.2 to 0.5 % molar-to molar or only 0.1 to 0.2 mm) with heat cured acrylic resin dentures as they were deflasked. Some of the internal stresses from processing are released when the denture is deflasked and polished as it becomes slightly narrower from molar-to molar and flange to flange. This linear shrinkage is invariably small, less than 0.5% (0.2 mm) slightly more on lower dentures than on uppers which are in accordance to the results of present study.

It has been reported by Anusavice2 that when methyl methacrylate is polymerized the density changes from 0.945 g/cm3 to 1.19 g/cm3, which results in a volumetric shrinkage of 21% for pure monomer (polymerization shrinkage) during its polymerization. The mixture used for fabrication of dentures apparently contains 1/4 to 1/3 of monomer and as might be expected the volumetric shrinkage will usually range from slightly over 5% to about 7%. Based on a projected volumetric shrinkage of 7%, an acrylic resin denture base should exhibit a linear shrinkage of 2%3.

Anthony and Peyton1 inferred that shrinkage might be expected somewhat less in the lower dentures because of the short linear distances between the labial or buccal and the lingual borders.

The present study shows the linear shrinkage from 0.25-1.42%, which is also in accordance with the study done by Anusavice2, Noort7, and Shippee9. The resins were all found to shrink during the curing process. However, on immersion in water, the resins were found to expand. He reported greater shrinkage during processing than during storage in water up to 90 days.

It is assumed that curing shrinkage is entirely thermal in nature and for a given resin composition, it will depend upon the temperature at which the resin becomes sufficiently rigid to contract thermally independent of the cast or model. The present study showed significant linear dimensional changes after curing and after finishing and polishing.

SUMMARY AND CONCLUSION:

The study was carried out to study the linear dimensional changes of four different heat cure acrylic resins before and after curing, before curing and after finishing and polishing and after curing and after finishing and polishing and to compare the linear dimensional changes of heat cure acrylic resin among four different acrylic brands.

The conclusions drawn from the study are as under:

1. All the materials showed linear changes immediately after curing and after finishing and polishing.

2. Among four materials i.e. Meliodent, Trevalon, Triplex and Vertex maximum percentage changes after curing were seen in Group-A (Meliodent- 1.18%) followed by Group-B (Trevalon- 0.71%), Group-C (Triplex- 0.51%) and Group-D (Vertex- 0.37%).

3. After finishing and polishing maximum percentage changes were seen in Group-A (Meliodent- 1.41%), followed by Group-B (Trevalon- 1.18%), Group-C (Triplex- 0.80%) and Group-D (Vertex- 0.61%).

4. After curing and after finishing and polishing maximum percentage changes were seen in Group-B (Trevalon- 0.46%) followed by Group-C (Triplex- 0.29%), Group-A (Meliodent- 0.28%) and Group-D (Vertex- 0.25%).

5. Among four materials compared, Group-D (Vertex) showed the least percentage changes after curing and after finishing and polishing (0.37% & 0.25%).

REFERENCES:

1. Anthony DH, Peyton FA. Dimensional accuracy of various denture base materials. J Prosthet Dent 1962; 12: 67-81.

2. Anusavice KJ. Phillip’s Sciences of Dental Materials. 12th ed. St. Louis. Saunders; 2004.p.721-57.

3. Becker CM, Smith DE, Nicholls JI. The comparison of denture-base processing techniques. Part II. Dimensional changes due to processing. J Prosthet Dent 1977; 37: 450-5.

4. Dixon DL, Breeding LC, Ekstrand KG. Linear dimensional variability of three denture base resins after processing and in water storage. J Prosthet Dent 1992; 67: 196-200.

5. Kinner EW, Cooper EN. Physical properties of denture base resins: Part I. Curing shrinkage and water sorption. J Am Dent Assoc 1943; 30: 1845-52.

6. Komiyama O, Kawara M. Stress relaxation of heat-activated acrylic denture base resin in the mold after processing. J Prosthet Dent 1998; 79: 175-81.

7. Noort R. Introduction to Dental Materials. 2nd ed. St. Louis. The Mosby Company; 2005. p. 214.

8. Stafford GD, Bates JF, Huggett R, Handley RW. A review of the properties of some denture base polymers. J Dent 1980; 8: 292-306.

9. Shipee RW. Control of increased vertical dimension of compression-molded dentures. J Prosthet Dent 1961; 11: 1080-5.

10. Woelfel JB. Processing complete dentures. Dent Clin North Am 1977; 21: 329-38.

11. Woelfel JB, Paffenbarger GC, Sweeney WT. Dimensional changes occurring in dentures during processing. J Am Dent Assoc 1960; 61: 413-30.

12. Zissis A, Huggett R, and Harrison A. Measurement methods used for the determination of dimensional accuracy and stability of denture base materials. J Dent 1991; 19: 199-206. |