Introduction

Dental casting is one of the most widely used methods of fabrication of metallic restorations outside of the mouth. Taggart in 1907 first used the process for producing gold inlays[1]. Since then for decades, various metals and their alloys have been used in dental practice to fabricate cast dental prosthesis. The casting procedure consists of constructing a wax pattern which is an intricate shape of the metallic structure required. The wax pattern is attached with the sprue. The purpose of sprue former or sprue pin, is to provide a channel through which molten alloy can reach the mould in an invested ring after the wax has been eliminated[1].

Investment material is poured around the wax pattern in a fluid state. When the investment sets hard the wax and the sprue former are eliminated by softening and burnout to leave a mould empty for filling up the molten liquid[8]. The solidified alloy considered to be the solid metallic structure. It is an accepted fact that the investment mould used for casting alloys needs to be constructed from a material which retains its integrity at the casting temperature. Unmodified dental plasters or stones are not suitable for this purpose[14]. Phosphate bonded investments are such investments which have sufficient strength at the high temperatures used for casting base metal alloys.

The strength of the phosphate bonded materials is aided by the formation of silicophosphates on heating.

A sprue is the channel in a refractory investment mould through which molten metal flows. After the wax pattern has been made, either directly on a prepared tooth or on a die replica of the tooth, a sprue former base is attached to the sprued wax pattern, and it is surrounded with investment[8]. Factors such as diameter, direction, position, attachment & length of the sprue and the distance of the mould cavity from the base of the mould all have an effect on the quality of the casting[10], [15]. However there are not many studies that have shown about the role of number of sprues attached to the wax pattern which can reduce discrepancy and also defective castings.

The sole objective of the casting procedure is to provide a metallic duplication of missing tooth structure with as great as accuracy possible[2]. The evaluation of accuracy of the restoration is possible by its marginal adaptation using an explorer and roentgenograms microscopic evaluation was also done by measuring marginal openings of the occlusal, proximal and gingival margins. With the limited literature review of casting accuracy obtained by the phosphate bonded investment and different number of sprues, the following study has been conducted in SRM Dental College, in the department of prosthodontics.

The Objectives Of The Study Are

1. Comparison of casting accuracy by using Single sprue with Bella vest and Wiro vest investment material.

2. Comparison of casting accuracy by using Double sprue with Bella vest and Wiro vest investment material.

3. Comparison of casting accuracy by using Single sprue and Double sprue with Bella vest investment material.

4. Comparison of casting accuracy by using Single sprue and Double sprue with Wiro vest investment material.

5. Comparison of casting accuracy by using single sprue and double sprue with both Bella vest and Wiro vest investment materials.

6. Comparison of casting accuracy by using Bella vest and Wiro vest investment materials with single and double sprues.

Material And Methods

The metal dies were made using Aluminium block. Two blocks used for the study was rectangular in form of 1.25 centimetre thickness, length of 3cm and breadth of 2.5cm. A rectangular space of 5mm depth and 10mm radius was milled in the centre portion of aluminium block and provision of space in the centre of block was provided for standardizing the exact location of attachment of sprue and the width of the space is 3.5mm for one metal die and the other block has provision for standardization of location for attachment of two sprues of the same width using the computerized milling machine.

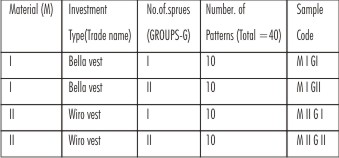

Red crown (Bego Germany) casting wax was used for the preparation of wax specimens of dimensions as per the metal die. The molten wax was filled into the space created in the aluminium block as per the dimensions mentioned for the specimens. The wax was allowed to cool in room temperature. The wax specimens were removed from the block without any damage or distortion. A total of 40 wax patterns were made for two different investment materials (M I and M II) and two different sprue number (Group I and Group II). 10 wax patterns for each investment and sprue number were prepared with 100 % New alloy and divided into 4 groups namely M I GI, M I G II, M II G I, and M II G II. All the wax patterns have been put up in the Table No: 1 and coded accordingly.

To provide a path for molten alloy to flow into the mould, sprue wax (Bego Germany) 3.5mm was attached to the wax pattern at standardized location provided in the die. A total of 20 wax patterns were fabricated with single sprue attachment and 20 wax patterns were fabricated with double sprues. Flaring of sprue at the point of attachment is done. Sprue attachment also provided a method of removing of the pattern from die. Length of the sprue (10mm) was adjusted so that the pattern was 6 mm from the top of investment.

Prior to investing, patterns were thoroughly cleaned with debubblizer. Debubblizer was sprayed on the wax patterns to improve its wettability by decreasing the surface tension of the investment. Phosphate bonded investment was vacuum mixed as per the manufacturer’s instructions using vacuum investing equipment to eliminate air bubbles and to produce fine castings. Brush on technique was used for investment of patterns and investment is poured into the ring by placing it on a vibrator which offers variation in intensity and frequency of vibration. All the investments were allowed to bench set for one hour before being kept for the burn out. Thus, a total of forty investment moulds were prepared for the casting purpose. Multiple stages of burnout temperature were used to achieve 950o c temperature over a period of one and half hours to prevent mould cracking and damage during heating. The burnout ring is transferred to the casting machine when it reaches 950o C. Induction casting machine (Bego Germany) provides the means for transferring the molten alloy from crucible to mould and casting is done according to the manufacturer’s instructions. After completing bench cooling the casting ring was divested and sandblasted using 0.5 mm Aluminium oxide to remove the remnant investment material. Sprues were cut off and specimens were finished using Carborundum discs and high speed motor instruments. Thus forty castings were made for evaluation.

Cast specimens were evaluated for marginal rounding using a methodology proposed by Brockhurst et al and Chan et al. The method is based on direct technique using a dental impression to record the margin configurations. The cast specimens were lowered into putty light body addition silicone impression material.

After polymerization of impression material cast specimens were removed from rectangular block. Each silicone impression was then cut into two equal size segments using razor blade and cutting guides located at rectangular blocks. The silicone sections were positioned over the glass slab. The superior section was marked with a permanent marker pen. Each impression has two faces, only marked face was measured. The silicone sections were positioned under an inverted incident optical profile projector (Deltronic dv115) with a precision of 0,001mm was used to measure the depth and number of depressions under 20 X magnifications. The number and depth of depressions in the impression surface of all the four groups are measured by using the reader scale in the optical profile projector.

This depth had been measured initially ma¬tching the horizontal line of the profile projector with the vertex that divided horizontally the pattern in the middle, at the same time that the vertical line of the profile projector matched with the apex of the margin. Afterwards, the table was dislocated horizontally until the end of margin crossing and data was registered.

Results

The final result was calculated using the mean value of the readings to each pattern. Subsequently, it was compared the mean value of castings’ inaccuracies with the depths between the one end of margin to the other end of the impression matrix, obtaining the dimensional alteration mean value. Lower mean values indicate that a better compensation was obtained with both investments with different and same sprue number of casting.

Discussion

Many of the variables such as marginal fit, surface roughness, porosities and incomplete casting, which influence accuracy of the casting and ultimate clinical success of the restoration, have been controlled by the dentist or technician using empirical experience as a guide[11]. The properties of the alloys used, and certain other manipulative variables[12], one of the important facets is the critical evaluation of the influence of investments and sprue number commonly employed with nickel chromium alloys.

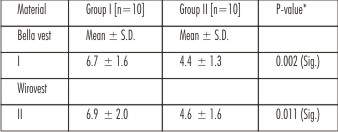

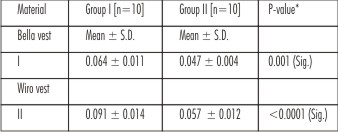

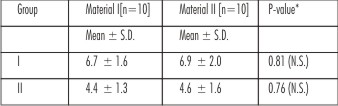

In this study evaluating the number of depressions in impressions among different materials and sprue number observed, indicating the potential for casting accurate margins. The results of the study imply that sprue number is more critical by far than the investment material type. The evaluation of the two investments, in terms of the number of sprues per casting, showed that the use of Two sprues(Group II) provided a significant reduction of the marginal deficiencies recorded for investment material M I (Bellavest), thus producing results similar to those obtained for investment material M II (Wirovest), (Table V and VI). For investments that are more prone to react with alloy, such as investment M I, the use of two sprues promotes a higher molten metal velocity, facilitating proper mold filling.This couldcompensate for potential negative effects resulting from reactions between alloy and the mold[3].

| Table No: 1

|

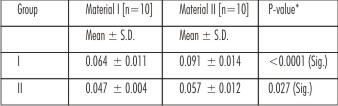

| Table No: 2 Mean Standard Deviation And Test Of Significance Between (MI GI)-(MI GII) & (MII GI -(MII GII) Of Number Of Depressions Obtained In Each Sample Made Of Polyvinyl Siloxane Material Of Casted Samples Which Were Invested Using Bella Vest Investme

|

| Table No: 3 Mean Standard Deviation And Test Of Significance Between (MI GI)-(MI GII) & (MII GI)-(MII GII) Of Depth Of Depressions Obtained In Each Sample Made Of Polyvinyl Siloxane Material Of Casted Samples Which Were Invested Using Bella Vest Investmen

|

| Table No: 4 Mean Standard Deviation And Test Of Significance Between M I And M II Of Number Of Depressions With G I - G II Of Number Of Depressions Obtained In Each Sample Made Of Polyvinyl Siloxane Material Of Casted Samples Which Were Invested With Bell

|

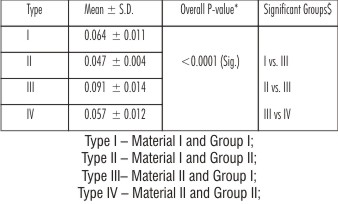

| Table No: 5 Mean, Standard Deviation And Test Of Significanceof The Depth Of Depressions Between M I M II For G I. And MI MII For G II shows The Mean, Standard Deviation And Test Of Significance Of The Depth Of Depressions Between Material I (Bella Vest)

|

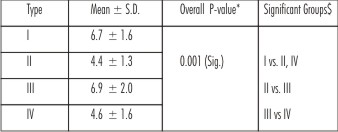

| Table No: 6 Mean, Standard Deviation And Test Of Significance Of The Number Of Depressions Between MI M II And G I G II. Shows The Mean, Standard Deviation And Test Of Significance Of The Number Of Depressions Between Different Materials (I And II) And Di

|

| Table No: 7 Mean, Standard Deviation And Test Of Significance Of The Depth Of Depressions Between MI M II And G I G II.Shows The Mean, Standard Deviation And Test Of Significance Of The Depth Of Depressions Between Different Materials (I And II) And Diffe

|

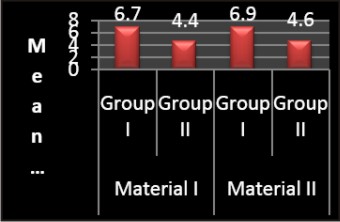

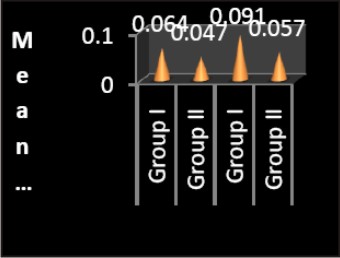

| (Graph: 1) Mean Number Of Depressions

|

| (Graph: 2) Mean Depth Of Depressions

|

This finding of the present study may be significant, considering factors related to investment M I. It is less expensive, easier to manipulate, and less sensitive to desiccation when compared to investment M II. Since the use of Two sprues (Group II) significantly reduced marginal deficiencies for both investments to a level of similarity (Fig. 1 and 2), than single sprued pattern (Group I) prosthodontic laboratories may prefer to use investment M I as a practical, simple technique that is also more economical. It was difficult to compare the results of the current study with those obtained in other studies, as different methods were used to evaluate marginal accuracy[4],[5],[6],[7]. This study evaluated the influence of investment type and sprue number to produce complete, void free castings made from nickel-chromium alloys.

In the present study, marginal accuracy measurements depended on a metal die simulating the configuration of a tooth prepared to receive a cast metal complete crown. However, the results obtained cannot be directly interpreted as clinically relevant, since factors such as the fit of the crowns and thickness of a cement layer were not evaluated. Additionally, further investigations are needed to determine the importance of mold vents and different sprue configurations that could improve the accuracy of casting techniques.

Conclusion

Considering study methodology and limitations, the following conclusions were drawn:

1. The optical profile projector (Deltronic -- DV114) are useful in evaluating the depth and number of depressions in the impressions of casted nickel –chromium alloys.

2. The phosphate –bonded investment (Bella vest) provided significantly better casting accuracy for Ni-Cr crowns compared to the phosphate–bonded investment (Wiro vest).

3. The marginal accuracy of crowns cast with Ni-Cr was significantly better when two sprues were used rather than one sprue.

4. The phosphate– bonded investment (Wiro vest) provided casting accuracy similar to that obtained with the phosphate–bonded investment (Bella vest) when two sprues were used in casting Nickel-Chromium crowns.

5. The connection between the casting, sprue number and investment type should be constricted to improve casting accuracy of nickel- chromium alloys.

6. Although this spruing and investing techniques may be used in different designs and methods to improve the quality of castings, further research seems indicated.

References

1. Anusavice KJ. Phillips science of dental materials. 11th edition. St.Louis: Saunders; 2003. Page No. 563-620.

2. E. K. -H. Ho, B. W. Darvell; A new method for casting discrepancy: some results for a phosphate-bonded investment: J Dent 1998; 26: 59-68.

3. F. A. Marsaw, W. G. de Rijk, R. A. Hesby, R. W. Hinman, and G. B. Pelleu; Internal volumetric expansion of casting investments: J Prosthet Dent1984; 52: 361-66.

4. HenryA.Collett ;Casting chrome-cobalt alloys in small laboratories: J Prosthet Dent1969; 21: 216-26.

5. Hero H, Syverud M, Waarli M. Mold filling and porosity in castings of titanium. Dent Mater 1993; 9:15-8.

6. Hruska AR, Borelli P. Quality criteria for pure titanium casting, laboratory soldering, intraoral welding, and a device to aid in making uncontaminated castings. J Prosthet Dent 1991; 66:561-5.

7. H.W.-K. Luk, B.W. Darvell; Casting system effectiveness— measurement and theory: Dent Mater1992; 8: 89-99.

8. Preston JD, Berger R. Some laboratory variables affecting ceramo-metal alloys. Dent Clin North Am 1977; 21:717-28.

9. R. Compagni, R. R. Faucher, and R. A. Yuodelis; Effects of sprue design, casting machine, and heat source on casting porosity: J Prosthet Dent1984; 52: 41-45.

10. Rieger MR, Tanquist RA, Vainer S. The effect of a new sprue design on the castability of a base-metal alloy. J Prosthet Dent 1986; 55:686-90.

11. Richard J. Schnell, George Mumford, Ralph W. Philiphs; An Evaluation of Phosphate Bonded Investments Used With a High Fusing Gold Alloy. J Prosthet Dent 1963; 13:324-36.

12. Shelby, D.S.: Practical Considerations and Design Of Porcelain Fused to Metal, J. Pros. Den:1962; 12: 542.

13. Verrett RG, Duke ES. The effect of sprue attachment design on castability and porosity. J Prosthet Dent 1989; 61:418-24.

14. Yakushi. Investments and their accuracies; J Oral Rehabil; 1997; 24: 7:532-9.

15. Young HM, Coffey JP, Caswell CW. Sprue design and its effect on the castability of ceramometal alloys. J Prosthet Dent 1987; 57:160-4.

|