Introduction

The extraction-non extraction debate, ongoing for almost 100 years, has often been based more on supposition than fact[1]. The pendulum has swung back and forth over the years between an overabundance of extraction cases and then the same with non extraction cases.Although the percentage of patients with dished in profiles after extraction treatment has been found to be very small, but elective tooth extraction is often an emotive issue for the patient. This has led this pendulum to swing back into non extraction mode in recent years and to the increasing tendency for nonextraction therapies such as proximal stripping, lateral, anterior and posterior expansion of the dentition, molar distalization and space regainers[2].

Interproximal reduction, interdental reduction, reproximation, recontouring, slenderizing, coronoplastia and Hollywood trim are some of the various terms used to describe proximal stripping[3].The various indications of interdental stripping include correction of tooth size discrepancies, creation of space to correct malocclusions, enhancement of retention and stability, simulation of stone age man’s proximal attrition and improvement in aesthetics and shape of teeth.

There have been multiple opinions on the actual amount of tooth structure to be removed, however, a general consensus existing among orthodontists is that 0.3-0.5 mm of enamel can be removed from each proximal surface without jeopardising its health[3].

Proximal reduction generates the formation of grooves and valleys mainly in the cervical region of the teeth creating plaque retentive areas[4],[5],[6]. Polishing with finer abrasives is necessary to achieve a subsequent reduction of grooves caused by coarse abrasives[7].

Materials And Methods

Ninety eight caries free human maxillary premolars extracted for therapeutic reasons were included in this study. The extracted teeth were rinsed in water to remove any blood or tissue remnants and stored in deionized water[8] until needed. They were randomly divided into seven groups of fourteen teeth each. Each group was mounted in plaster and was aligned in an arch form with colour coding for the purpose of identification. Each group was subjected to proximal stripping with one of the following methods (Figs.I,II) :

| Fig. I - Stripping with various methods; (a) use of 16 blade tungsten carbide bur (b) use of diamond disc (c)use of diamond coated metal strip

|

| Fig. II- Polishing with various methods;(a) use of fine soflex disc (b) use of fine diamond bur

|

Group A : Control group; no stripping was performed.

Group B : Stripping with 16-blade tungsten carbide bur( H133F,Komet)and polishing by means of fine sof-lex disc (4931 F;3M-ESPE) .

Group C : Stripping with 16 blade tungsten carbide bur and polishing by means of fine diamond bur (859 F;Komet) .

Group D : Stripping with diamond disc(808-C-160,Horico,Hopf, Ringleb ,Co., Berlin, West Germany) and polishing by means of fine Sof-lex disc .

Group E : Stripping with diamond disc and polishing by means of fine diamond bur .

Group F : Stripping with diamond coated metal strip( Horico,Hopf, Ringleb & Co., Berlin, West Germany) and polishing by means of fine sof-lex disc .

Group G : Stripping with diamond coated metal strip and polishing by means of fine diamond bur .

In all groups, stripping included water cooling , similar pressure on the instruments and reduction of 0.3 mm, which was measured with the help of incremental thickness gauge. Polishing time was standardized for 20 sec.

After completion of the stripping and polishing procedures, the teeth were subjected to ultrasonic cleaning and then dehydrated in ascending degrees of alcohol.

After the dehydration process, samples were placed in a dessicator for 24 hours. The dried specimens were mounted on aluminium stubs, sputter coated with gold for 2 minutes in a fine coat with JEOL ION SPUTTER JFC-1100 SPUTTERING DEVICE .

The mounted specimens were observed under scanning electron microscope using model JEOL JSM-6100 operated at 20 Kv and 1000X magnification.

Photomicrographs were converted to grey scale for application to the digital image processing software. (Image J 1.43 version).Surface plots of the images were then scored according to the following criteria:

• Perfect surface, no peaks

• Satisfactory surface, fine peaks

• Acceptable surface, some low and some high peaks

• Imperfect surface, several distinct high peaks

• Unacceptable surface, very high peaks distributed all over the plot

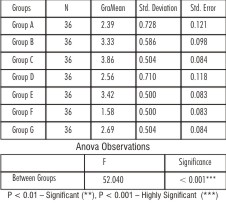

The assessment procedure of the surface plots was carried out by three independent evaluators who had no knowledge of which plot represented the various surface studied. To rule out interexaminer variability, means of all values were taken (Table-1).

The data thus obtained was compiled and put to one way ANOVA and Post hoc multiple statistical tests (Table-2).

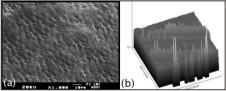

| Fig. III – Photomicrograph (a) and surface plot (b) of respective representative of group A

|

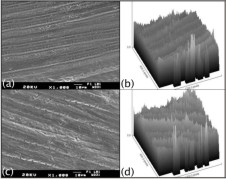

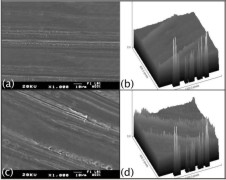

| Fig. IV – Photomicrograph (a) and surface plot(b) of respective representative of group B. Photomicrograph (c) and surface plot(d) of respective representative image of group C

|

Observations And Results

Under the scanning electron microscope, all stripping protocols resulted in roughened and grooved enamel surfaces.

Control group (group A) showed enamel surfaces that were not completely smooth. Small number of furrows and irregularities were distributed over the entire surface with rounded rims and interspersed with smooth areas. Heads of the enamel prisms could be seen on the surfaces (Fig.III a).

Stripping with tungsten carbide bur and polishing with fine sof- lex disc (group B) created a small number of furrows distributed over the entire surface and interspersed with rough areas (Fig. IV a).

The use of fine diamond bur after stripping with tungsten carbide bur (group C) produced deep furrows that were distributed irregularly over the entire surface and interspersed with notably rough areas (Fig. IV c).

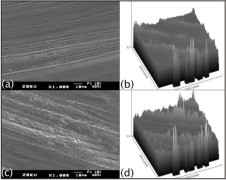

After stripping with diamond disc and polishing with fine sof-lex disc (group D), the surface appeared finely rough. Though the use of fine sof-lex disc appeared to reduce the rough appearance of the stripped surface, it still exhibited the underlying appearance of the stripping procedure (Fig. V a).

Diamond disc stripping and polishing with fine diamond bur (group E) produced a rough surface in which furrows could be seen crossing at different depths. The surface exhibited distinct deep regular parallel grooves. (Fig. V c).

The use of diamond coated metal strip followed by polishing with fine sof-lex disc (group F) created surfaces that were reasonably smooth. The enamel surface appeared crossed by few fine and shallow furrows alternating with well polished areas (Fig.VI a).

Diamond coated metal stripping and polishing with fine diamond bur (group G) created many fine furrows distributed over the entire surface and interspersed with some smooth areas (Fig.VI c).

To be more closely compared, surface plots for the respective photomicrographs were made by Image J software 1.43 versions (Fig. III to VI) and these surface plots were further scored by 3 evaluators using the index.

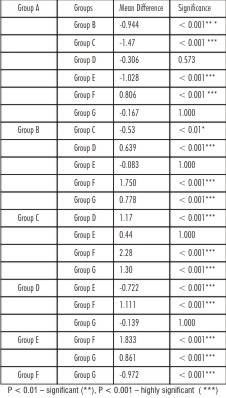

Group A (control group) on comparison with groups B, C, E and F showed statistically significant smooth surfaces (p < 0.001**) and comparison with groups D and G showed insignificant results in terms of smoothness (Table 2).

Groups B and C on comparison with groups A, D, F and G showed statistically significant rough surfaces (p < 0.01*) and comparison with group E showed insignificant results. Groups B and C when compared among themselves showed significant results indicating soflex disc is better than fine diamond bur for polishing (Table 2).

Group D on comparison with groups B, C and E produced statistically significant smoother surfaces and when compared with group F produced significantly rough surfaces (p < 0.001**). (Table 2)

Group F on comparison with groups A,B,C,D,E and G showed statistically significant smoother surfaces (p < 0.001**). The method produced significantly smoother surfaces than the control group as well (Table 2).

Group G when compared with groups B, C and E showed statistically significant smooth surfaces (p < 0.001**) and there was no significant difference between roughness scores of groups G, A and D (Table 2).

| Fig. V – Photomicrograph (a) and surface plot(b) of respective representative of group D. Photomicrograph (c) and surface plot(d) of respective representative of group E

|

| Fig. VI – Photomicrograph (a) and surface plot(b) of respective representative of group F. Photomicrograph (c) and surface plot (d) of respective representative of group G

|

| Table- 1:Comparison of mean surface roughness values of various groups using one way ANOVA test

|

| Table- 2: Comparison of one group with other groups using Post Hoc Multiple test

|

Discussion

Management of space problems continues to play an important role in Orthodontics. Commonly used methods for creating space in order to facilitate tooth movement are expansion, extraction or tooth slenderization. Proximal stripping is routinely carried out to avoid extraction in borderline cases where space discrepancy is less and in cases where there is a discrepancy between the mesiodistal width of maxillary and mandibular teeth to satisfy Bolton ratio[9],[10].

Over the years, a wide array of methods have been employed to reduce the enamel in a controlled manner with minimum substrate alterations[11]. Researchers have confirmed with many studies that all these methods, in general, leave a rough surface and polishing should follow every stage of stripping.[11],[12]

Following conservative reduction and polishing with different techniques and materials, enamel surfaces were evaluated by scanning electron microscope.

The particular advantage of the SEM in studying the enamel surface is its resolution and large depth of field, which provides an excellent means of topographic assessment,[13],[14],[15],[16],[17],[18],[19].

The SEM analysis revealed that the untreated enamel surfaces, have a rough uneven appearance due to the presence of the perikymata with equal proportions of crests and troughs. The findings are consistent with the findings of Piacentini and Sfondrini[7], Chirla A[15], Lucchese A[18] and Vickers[20].

It was apparent from the observations of scanning electron microscope that all tested enamel reduction methods altered the surface of the enamel significantly by producing furrows and grooves. Changes in enamel morphology due to stripping methods have also been reported by Piacentini and Sfondrini[7], Ayca Arman[8], V.P.Joseph[16], Luccheese[18], Gholamareza Danesh[21] and many others.

In the study, diamond coated metal strip followed by sof lex disc (Group F) produced the smoothest surface (mean roughness score 1.58) .This could be attributed to the abrasive particle size of diamond coated metal strip (30 µm). Similar results were given by Ayca Arman[8] who found out that stripping with metal strips followed by polishing with fine sof lex discs produced the smoothest enamel surface.

On the whole, the results demonstrated that smoother enamel surfaces were obtained when sof lex polishing disks were used after stripping. This could be due to the abrasive points of sof-lex discs which are less rigid, fine textured and less porous compared to fine diamond abrasive points[15].These findings are in concurrence with the findings of Zhong et al[17] who concluded that polishing with 3 sof lex discs produced surfaces smoother than untreated enamel. Piacentini and Sfondrini[7] and Chirla A[15] too reported that with the use of sof lex discs for polishing of enamel, it was possible to eliminate the furrows left by stripping methods and attain well polished surfaces.

The enamel surface after the use of diamond coated metal strip followed by fine sof-lex disc when compared with normal untreated enamel produced smoother surface as also reported by Zhong et al[17].

According to Rosenblum[22] and Craig, O’Brien and Powers[23], the main factors which affect enamel reduction are particle size of the abrasive, particle shape of the abrasive, lubrication ,speed at which the abrasive travels across the surface being abraded and the pressure of the abrasive agent against the surface being abraded or polished.

The last three factors were controlled in the study and the first two factors are controlled by the choice of the product used. The larger and more irregular shaped the abrasive particle, the coarser and deeper will be the scratches, though the quicker the surface will be reduced. In this study, it was observed that though the diamond disc reduced the proximal surface fast than diamond strip but it left the rough surface even after polishing due to large abrasive particles.

Overall, the findings demonstrated that, out of the tested methods, stripping with diamond coated metal strips followed by polishing with so flex discs (Group F) produced the smoothest enamel surface. Though polishing with sof-lex disc achieved well polished areas (smoother than untreated enamel surfaces), nevertheless, compared with intact enamel, other experimental groups had rougher surfaces with many furrows and grooves. Thus, hygiene instructions, including interproximal plaque control and prophylactic measures such as topical fluoride application, must be given after interdental stripping to prevent undesirable sequelae of the procedure.

Conclusions

From the study, following conclusions were drawn:

1. The enamel surfaces after stripping with diamond coated metal strip and polishing by fine sof-lex disc (group F) were the smoothest.

2. Sof-lex discs were more efficient than fine diamond burs in polishing the stripped enamel surfaces.

In conclusion, given the current emphasis on non-extraction treatment in Orthodontics today, stripping is a technique that can increase space but must be performed with the best possible finishing of the interproximal enamel surface that meets the biological requirements of the oral cavity.

References

1. Case CS. The question of extraction in Orthodontia. Dent Cosmos 1912;54:137-57,276-84.

2. O’Connor BMP. Contemporary trends in orthodontic practice: a national survey. Am J Orthod Dentofacial Orthop 1993;103:163-170.

3. Pinheiro M. Interproximal enamel reduction. World J Orthod 2002;3:223-32

4. Radlanski RJ, Jager A, Schwestka R, Bertzbach F. Plaque accumulations caused by interdental stripping. Am J Orthod Dentofacial Orthop 1988;94:416-20.

5. Radlanski R. Morphology of interdentally stripped enamel one year after treatment. J Clin Orthod 1989; 23:748-750.

6. Crain G, Sheridan JJ. Susceptibility to caries and periodontal disease after posterior air-rotor stripping. J Clin Orthod 1990; 24:84-85.

7. Piacentini C, Sfondrini G. A scanning electron microscopy comparison of enamel polishing methods after air-rotor stripping. Am J Orthod Dentofacial Orthop 1996;109:57-63.

8. Arman A, Cehrali BS, Ozel E, Arhun N, Cetinsahin A, Soyman M. Qualitative and quantitative evaluation of enamel after various stripping methods. Am J Orthod Dentofacial Orthop 2006;130:131.e7-131.e14.

9. Sharma NS, Shrivastav SS, Hazarey PV. Mastering interproximal stripping: With innovations in slenderization. Int J Clin Pediatr Dent 2012;5(2):163-66.

10. Johner AM, Pandis N, Dudic, Kiliaridis S. Quantitative comparison of 3 enamel stripping devices in vitro: How precisely can we strip teeth? Am J Orthod Dentofacial Orthop 2013;143:168-72.

11. Gioka C, Eliades T. Interproximal enamel reduction (stripping): indications and enamel surface effects. Hel Orthod Rev 2002;5:21-32.

12. Chudasama D, Sheridan JJ. JCO interviews on air rotor stripping. J Clin Orthod 2008; 42:381-388.

13. Chudasama D, Sheridan JJ. Guidelines for contemporary air-rotor stripping. J Clin Orthod 2007;41:315-320.

14. Sheridan JJ, Ledoux PM. Air-rotor stripping and proximal sealants. An SEM evaluation. J Clin Orthod 1989;23:790-94.

15. Chirla A, Kumar N, Jayakumar P. A scanning electron microscopic comparison of re-proximated enamel surfaces after various stripping and polishing methods- an in vitro study. J Ind Orthod Soc 2010;12-24.

16. Joseph VP, Rossouw PE, Basson NJ. Orthodontic microabrasive reproximation. Am J Orthod Dentofacial Orthop 1992;102:351-9.

17. Zhong M, Jost-Brinkmann PG, Zellman M, Zellmann S, Radlanski RJ. SEM evaluation of a new technique for interdental stripping. J Clin Orthod 1999;33;5:286-292.

18. Luchesse A, Porcu F, Dolci F. Effects of various stripping techniques on surface enamel. J Clin Orthod 2001;35:691-695.

19. Mikulewicz M, Szymkowski J, Brzozowska TM. SEM and profilometric evaluation of enamel surface after air rotor stripping- an in vitro study. Acta Bioeng Biomech 2007;1:11-17.

20. Vickers DI. Proximal stripping and enamel surface roughness. Thesis(1982). Department of Preventive Dentistry,University of Sydney.

21. Danesh G, Hellak A, Lippold C, Ziebura T, Schafer E. Enamel surfaces following interproximal reduction with different methods. Angle Orthod 2007;77:1004-10.

22. Rosenblum M. Abrasion and polishing.An outline of dental materials. Edited by W.J. O’Brien and G.Ryze. W.B.Saunders company,Philadelphia 333-342.

23. Craig RG, O’Brien WJ, Powers JM. Finishing, polishing and cleansing materials.Dental materials properties and manipulation.2ndedition. The C.V. Mosby Company, St.Louis 88-93.

|