Introduction

Acrylic resins were introduced in 1936 as an alternative to vulcanized rubber and have been used to construct the bases of complete and partial removable dentures. Among their characteristics are easy handling, good thermal conductivity, low permeability to oral fluids and color stability.[1] Acrylic prostheses present excellent resistance to the oral environment, solvents and ultraviolet radiation. Despite these excellent properties it has got certain limitations like low strength, dimensional change during processing and greater water sorption. There is a risk of toxicity and hypersensitivity to the material due to products of oxidation and other components of the system.[2]

Nylon, a resin derived from diamine and dibasic acid monomers was developed as a result of the classic research by Carruthers and associates of the DuPont Chemical Company.[3],[4] These studies utilized nylon 66 and nylon 610. Although nylon was not recommended for general use at that time, it was used in special circumstances such as repeated denture fracture and for the construction of orthodontic appliance. While reporting the mechanical advantages of this polymer, they highlighted various disadvantages. These features included the tendency of the material to deteriorate in base color, to stain, show high water absorption, and to develop a roughness of the surface after a few weeks wear. These problems were not encouraging, and there was a scarcity of research on dental applications for nylon until 1971 when work on nylon 12 was completed.

The application of nylon-like materials to the fabrication of dental appliances has been seen as an advance in dental materials. Nylon exhibits high physical strength, heat resistance and chemical resistance. It can be easily modified to increase stiffness and wear resistance. Because of its excellent balance of strength, ductility and heat resistance, nylon is an outstanding candidate for metal replacement applications.[5]

Although the related literature presents studies assessing the properties of these nylon denture base materials in terms of deformation and prosthesis retention, there is a lack of information about modulus of elasticity indicating flexibility and water sorption associated to prosthesis deformation. Also very few studies till date have compared these properties among the different nylon denture base polymers and for different time intervals after immersion in simulated oral environment.

Considering the above prospective, the present study aimed to evaluate and compare the flexural modulus and modulus of elasticity of four different nylon denture base polymers.

Materials and methods

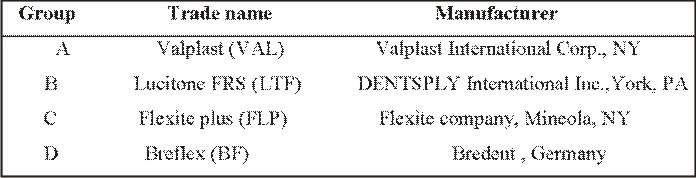

Four types of commercially available nylon denture base polymers (VAL, LTF, FLP, BF) were selected to evaluate flexural modulus and water sorption and were divided into four groups (Table 1).

| Table 1. Nylon Denture Base Polymers

|

Fabrication of Samples for determination of flexural modulus

Sixty cuboidal wax blocks were used for fabricating the samples. The fabrication was in accordance with ISO standard 1567:2005for testing the denture base materials.[6] Wax blocks were prepared using custom made metal mold and wax sprues were attached to them, which were then invested in die stone in aluminium metal flasks. Following dewaxing, two halves of the flasks were re-assembled together with cartridge containing melted nylon denture base polymer and were then placed in the flexible injection system. Firm pressure was applied until the spring of the press was fully compressed. Flasks were disengaged and samples were removed and finished to the dimensions of 64mm x 10mm x 2.5 mm.

Fabrication of Samples for determination of water sorption

Sixty solid metal discs of the dimensions 50+1mm diameter and 0.5 + 0.05mm thick were used for making specimens. It was in accordance with ISO standard 1567:2005for the testing of denture base materials.[6] Samples were prepared by investing the metal discs in die stone in aluminium metal flasks. Wax sprues were attached to the metal discs. Following dewaxing, metal discs were removed. Two halves of the flasks were reassembled together with cartridge containing melted nylon denture base polymers and placed in the flexible injection system. Firm pressure was applied until the spring of press would be fully compressed. Flasks were disengaged and samples were removed, finished and measured.

Testing of samples for determination of flexural modulus

Five samples for each nylon denture base material were immersed in artificial saliva for 1, 14 and 28 days and were tested accordingly.

A flexural three-point bending test was carried on the Universal Testing machine (Tinius Olsen, Model-H50KS). The dimensions of each specimen were entered into the program for computation. The distance between the two supporting wedges was 50 mm apart and the crosshead speed was set at 5 mm/minute.

The flexural modulus (E) was determined by calibrating the machine and the values automatically computed from the equation:

E = FL3/ 4 ybd3

Where E-flexural modulus (Mpa), F-maximum load exerted (N), L-distance between the supports (mm), y- deflection corresponding to load F at a point in the straight-line portion of the load–deflection curve, b-width of the specimens (mm), d-depth of the samples (mm).

Testing of samples for determination of water sorption

All the samples were immersed in artificial saliva for 1, 14 and 28 days and were weighed accordingly. After the respective time durations, wet weight of the one sample for “Group A” was recorded. The excess fluid accumulated on the sample was removed by drying it by filter paper. The sample was placed on Analytical balance and the reading was noted down. This reading was the wet weight of the sample. After that the sample was placed in dessicator and daily weight of the samples was recorded until a constant weight was obtained. This constant weight was the dessicated weight of the samples. The wet weight and dessicated weight of the remaining fifty nine samples of group (A, B, C and D) was recorded in the same manner as mentioned above after 1, 14 and 28 Days.

The percentage water sorption for all the samples of all the Groups and minor subgroups was then calculated by using following formula.[7]

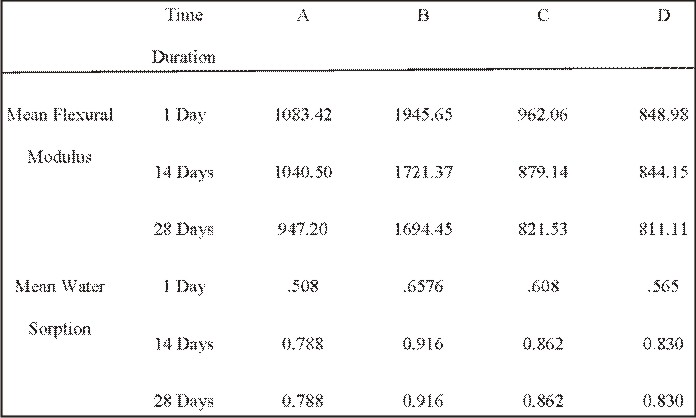

| Table 2: Mean Flexural Modulus (Mpa) And Percentage Water Sorption Of Nylon Denture Base Polymers At Different Time Durations.

|

Statistical analysis was made using a one-way analysis of variance, followed by Tukey’s multiple comparison test and the t-test at a significant level of p<0.05.

Results

Flexural Modulus

Table 2 shows the mean flexural modulus value of each nylon denture base polymer after 1 day,14 days and 28 days with maximal flexural modulus for LTF and minimal for BF.

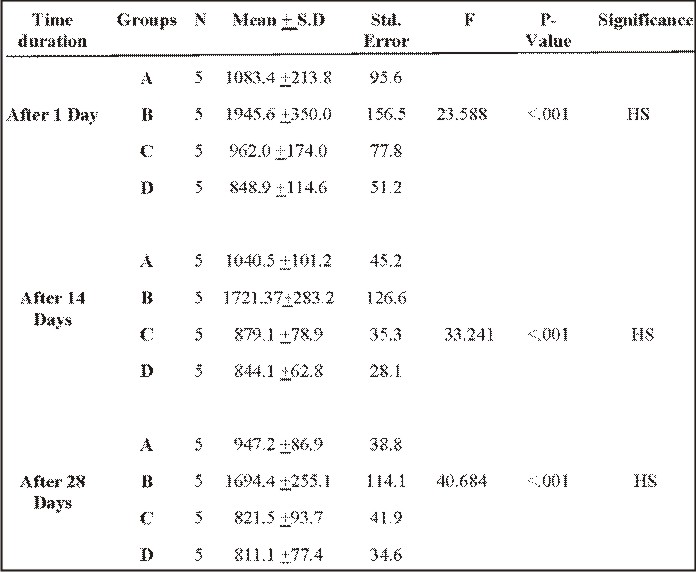

| Table 3: Statistical Comparison Of All The Groups For Flexural Modulus By Oneway Analysis Of Variance At Different Time Durations (1day, 14 Days And 28 Days).

|

Table 3 shows the comparison of all the groups for mean flexural modulus by oneway analysis of variance (ANOVA) at different time durations demonstrated a stastistically highly significant difference among the materials (p<0.001).

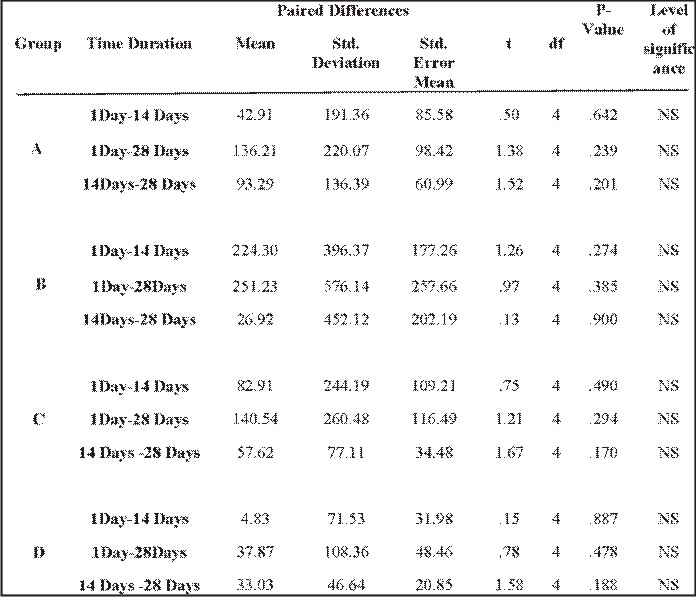

| Table 5: Intragroup Statistical Differences Between The Paired Samples Of Group A, B, C And D For Flexural Modulus At Different Time Durations (Paired âtâ Test)

|

Table 4 shows the multiple comparisons by Tukey post hoc test of significance for flexural modulus among the different groups under different time durations was utilized.The results showed statistically highly significant differences between group A and B, group B and C, group B and D (p<0.001) in terms of mean flexural modulus with respect to storage duration of 1,14 and 28 days. While comparisons between other groups were non-significant (p>0.05).

[Image 5]

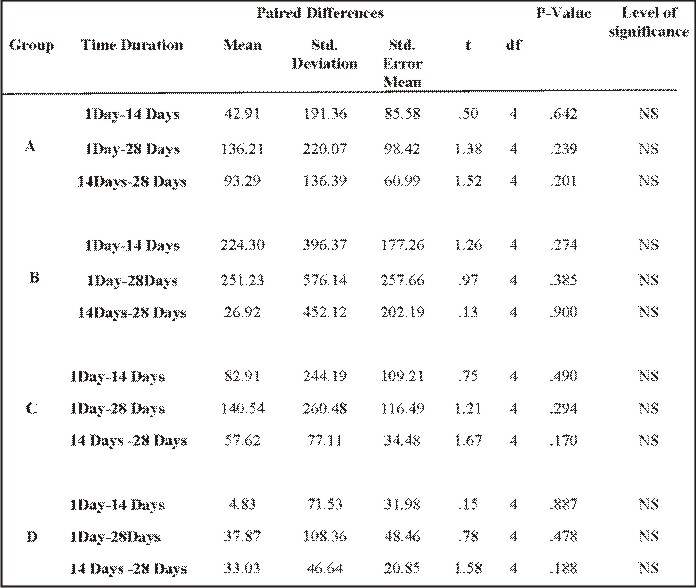

Table 5 shows the intra-group statistical differences between various paired samples for flexural modulus at different time durations was executed using student paired ‘T’ test that showed non-significant findings (p<0.05).

| Table 6: Statistical Comparison Of All The Groups For Water Sorption By Oneway Analysis Of Variance At Different Time Durations (1day, 14 Days And 28 Days)

|

Water Sorption

Table 2 shows the mean water sorption value of each nylon denture base polymer after 1 day,14 days and 28 days with maximal water sorption for LTF and minimal for VAL.

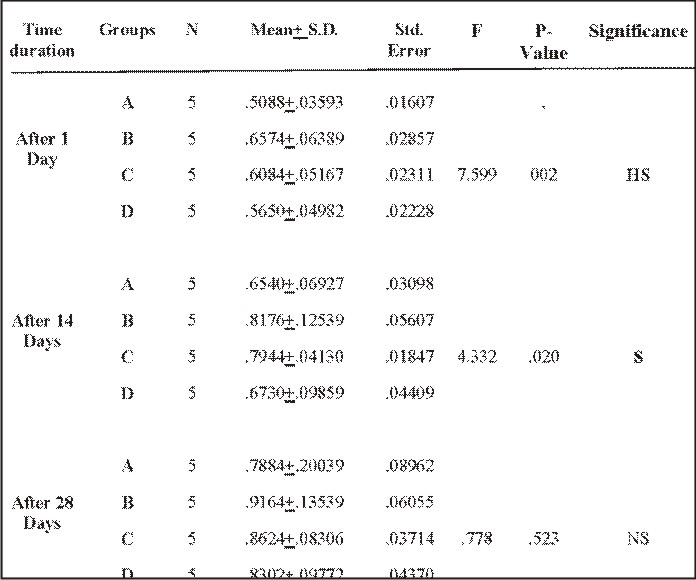

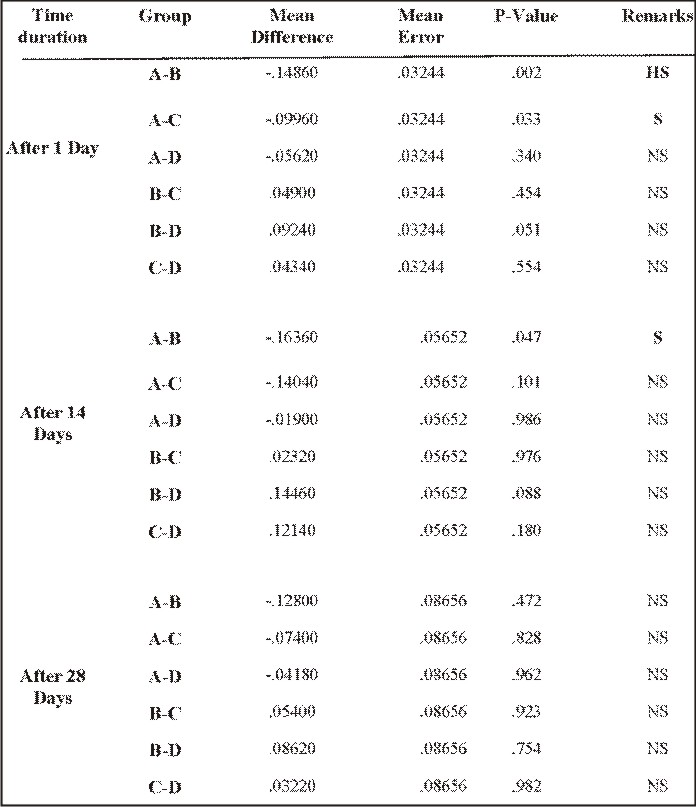

Table 6 shows the comparison of all the groups for mean water sorption by oneway analysis of variance (ANOVA) at different time durations demonstrated a stastistically highly significant difference among the materials after 1 day, significant difference after 14 days and non significant difference after 28 days (p<0.05).

| Table 7: Statistical Comparison Between The Groups After 1, 14, 28 Days For Water Sorption (Post Hoc Test).

|

Table 7 shows the multiple comparisons by Tukey post hoc test of significance for water sorption among the different groups under different time durations was utilized. The results showed statistically significant differences between group A and B (p<0.001) in terms of mean water sorption with respect to storage duration of 1 and 14 days and between groups A and C after storage duration of 1 day.While comparisons between other groups were non-significant (p>0.05).

| Table 8: Intragroup Statistical Differences Between The Paired Samples Of Group A, B, C And D For Flexural Modulus At Different Time Durations (Paired âtâ Test).

|

Table 8 shows the intragroup statistical differences between various paired samples for water sorption at different time durations was executed using student paired ‘T’ test that showed non-significant findings (p<0.05).

|

|

Discussion

It is a well known fact that nylon is promoted as a denture base material on the basis of its flexibility, which allows it to engage certain degree of undercuts for retention without these undercuts being blocked.

Many of the previous studies have compared nylon denture base polymers to the conventional denture base resins on the bases of their flexural modulus. HargreavesAS [7] reported the flexibility of nylon 12 but found that addition of 30% glass fibers to nylon 12 had the marked stiffening effect. First ever effort to compare the flexural properties of nylon to the PMMA resins was done by MacGregor AR et al.[8] They found nylon 12 denture base resin much more flexible then other PMMA denture base resins. Similar results were found by Stafford GD et al [9], Yunus N et al [2],Gladstone S et al. [10]

Till now, most of the previous studies have compared the flexural properties of nylon denture base polymers to the conventional denture base resins and found the nylon denture base resins to have lower flexural modulus and hence greater flexibility.[11] But very few studies have compared the different nylon denture base polymers among themselves in terms of flexural modulus under different storage intervals.

The present study was thus undertaken to compare the flexural modulus of four different nylon denture base polymers (Valplast, Lucitone FRS, Flexite Plus and Breflex) among themselves and under different storage durations in artificial saliva. The results showed highest flexural modulus with Lucitone FRS and lowest with Breflex under all the storage durations. As far as highest flexural modulus of Lucitone FRS is concerned, these results are in agreement to the previous study done by Takabayashi Y[12] ,who compared the flexural properties of nylon denture base resins (Lucitone FRS, Flexite Supreme and Valplast) to the other thermoplastic denture base resins (Polycarbonate resins and Polyethylene Terephthalate resins) and found nylon denture base resins to exhibit lower flexural modulus and hence confirming their flexible nature. Hamanaka I et al [13] in their study compared two nylon denture base polymers (Lucitone FRS and Valplast) to two other thermoplastic resins and one PMMA denture resin for their mechanical properties and found the nylon denture base polymers exhibiting lesser flexural modulus. Among the nylon denture base resins, Lucitone FRS was proved to be much more rigid than Valplast which was in concordance to the present study.

In addition to Lucitone FRS and Valplast, the present study included two other nylon denture materials namely Breflex (Bredent, Germany) and Flexite plus (Flexite company, NY) that was found to exhibit lower flexural modulus than the previous materials. Higher flexibility may form the basis by which retention through the use of undercuts on the remaining teeth can be obtained thus alleviating denture pain due to excessive local pressure. Though it is still a matter of research for the ideal rigidity of a denture, most workers believe that greater flexibility may prove to be favorable factor for denture base resins. However, the denture should be carefully designed since the displacement of soft tissue would be greater by denture flexibility. [12]

An ideal denture base material should also exhibit good mechanical properties and dimensional stability in moist environment. Many studies have shown the effect of storage condition on the properties of conventional denture base polymers and have concluded that water uptake decreases the mechanical properties of denture base polymers.

Takahashi Y et al[14] concluded from their study that the flexural properties of denture base materials decreased if the water sorption increased. Similar study conducted by Tham WL et al[15] found that reduction of flexural strength and modulus of the PMMA/HA composites after water absorption and simulated body fluid absorption could be attributed to the plasticizing effect of water molecules.But the English literature lacks the studies on the effect of water uptake on the flexural properties of the nylon denture base polymers.

In the present study, nylon denture base polymer specimens were immersed in artificial saliva to simulate the oral environment for 1day, 14 days (2 weeks) and 28 days (4 weeks). An insignificant decrease in flexural modulus was observed for the entire four nylon denture base resins used in the study and may be attributed to the absence of aromatic ring in the structure of nylon denture base polymers. Therefore, it is speculated that the penetration of water molecules into the polymer structure may have influenced the flexural modulus of nylon denture base polymers.[14] Further, such an insignificant difference in flexural modulus of the nylon denture base polymers after various storage intervals may favor their use as a good alternative to conventional denture base materials; since water uptake is known to decrease the mechanical properties of conventional denture base polymers.

The results of the present study showed increase in water sorption with increase in storage duration. The results of the present study were in agreement to the study performed by Stafford GD et al.[9] They evaluated the water sorption and some other properties of Flexiplast (nylon 12, Bredent, Germany) and Grilamid LKN-5H (nylon 12, Grilon, UK) denture base material after 1, 7 and 30 days of immersion in water and compared them with some conventional denture base resins. The results of this study showed lower water sorption of nylon denture base polymers as compared to conventional denture base resins but there was increase in water sorption with the increase in storage duration when compared within the group for both the nylon denture base resins.

Most of the previous studies showed that thermoplastic denture base resins have much lower water sorption than conventional resins. This may be due to the parallel relation between the level of residual monomer and percentage water sorption i.e. the percentage water sorption is higher in resins such as conventional resins with high levels of residual monomer.[16] Lower water absorption of thermoplastic resins may result in less oral fluid and bacterial incorporation into the resin base, thereby reducing the rate of bacterial growth and mouth odours.[17] These results indicated that a majority of the thermoplastic resins have a hygienic nature.

But thermoplastic resins include not only nylon denture base polymers (polyamides) but many other non-metal clasp denture base resins like acetal resins, polycarbonate resins and polyethylene teraphthalate resins.

In a recent study by Takabayashi Y[12], the author compared water sorption and some other properties between various non-metal clasp denture resins i.e polyamide resins (Valaplast, Lucitone FRS, and Flexite supreme), Polycarbonate resins (Reigning and Jet Carbo Resin) and Polyethylene terephthalate resin (Estheshot). Among the non-metal clasp denture materials, Polyamides tended to have inherently high water sorption values. Similar results were found by Takahashi H et al [18],who also concluded that polyamides have much greater water sorption values than other thermoplastic resins and one third water sorption values than conventional resins. This phenomenon was explained by the water absorption occurring among the molecular chains due to the high hydrophillicity of the numerous amide bonds forming the main chains of the polyamide resin. It is also thought that the higher the amide group concentration, the greater the water sorption. Therefore, authors suggested that the amide group concentration in the Polyamide type denture base materials could be adjusted to a level as low as that in popular industrial materials such as nylon 6 or 66. Such an adjustment would result in strong hydrogen bonding between amide groups and a reduction in attachment areas for water molecules; therefore, the amount of water sorption in Polyamide would decrease to the same level as nylon 6 or 66. [12]

All the previous studies compared water sorption of nylon denture base polymers with either conventional denture base resins or other thermoplastic resins. But very little studies compared these properties among different nylon denture base polymers. In the present study comparison was made only between different brands of nylon denture base polymers for different storage periods.

In the present study, among the four nylon denture base polymers, Lucitone FRS showed the highest water sorption and Valplast showed least water sorption values though the results were statistically non significant for Flexite Plus and Breflex group and showed similar percentage water sorption. As far as maximum percentage water sorption of Lucitone FRS was concerned, these results were in accordance with the earlier study by Takabayashi Y [12] who compared water sorption between three polyamide resins namely Valplast, Lucitone FRS, and Flexite Supreme. In their study, the author also concluded that Lucitone FRS had maximum water sorption.This may be due to the greater degree of hydrophillicity of Lucitone FRS as compared to other polyamide resins. For this it was assumed that polymers with higher water sorption tendency may have been used during the fabrication of Lucitone FRS. Valplast group in the present study had lesser water sorption values. Thus, it may prove more hygienic than the other three nylon denture base polymers used in the study.

Conclusion

Within the limitations of the study following conclusions were drawn

• Lucitone FRS showed highest flexural modulus while Breflex showed minimum flexural modulus values under all storage durations.

• All of the four nylon denture base resins showed very minimal decrease in flexural modulus after all the storage durations.

• Lucitone FRS showed highest water sorption while Valplast showed minimum water sorption values under all storage durations.

• All of the four nylon denture base resins showed increase in water sorption after all storage durations.

Disclosure: The author has no financial interest from the dealers of the product used in the study.

References

1. Phoenix RD. Denture Base Resins. In, Anusavice KJ. Phillip’s Science of Dental Materials, 11th edition. St. Louis, Missouri, Saunders, 2003;721-56.

2. Yunus N, Rashid AA, Azmi LL, Abu-Hassan MI. Some flexural properties of a nylon denture base polymer. J Oral Rehabil 2005;32(1):65-71.

3. Matthews E. Nylon as denture base material. Br Dent J 1955; 98:231-7.

4. Watt DM. Clinical assessment of Nylon as a Partial Denture base material. Br Dent J 1955;98:238-44.

5. Negrutiu M, Sinescu C, Romanu M, Pop D, Lakatos S. Thermoplastic resins for flexible frame work removable partial dentures. Timisoara Medical J 2005;55(3):295-9.

6. ISO 1567:2005, Dentistry-Denture base polymers, International Organization for Standardization.

7. Hargreaves AS. Nylon as a denture base material. Dent Pract Dent Rec 1971;22(4):122.

8. MacGregor AR, Graham J, Stafford GD, Huggett R. Recent experiences with denture polymers. J Dent 1984;12(2):146-57.

9. Stafford GD, Huggett R, MacGregor AR, Graham J. The use of nylon as a denture base material. J Dent 1986;14(1):18-22.

10. Gladstone S, Kumar A. A comparative evaluation of flexural properties of flexible denture base material and compression molded heat polymerized denture base material - an in vitro study. Kerala Dent J 2010;33(4):213-5.

11. Sakaguchi RL, Powers JM. Craig’s Restorative dental materials.12th edition. St Louis, Missouri, Mosby,2006;67-8.

12. Takabayashi Y. Characteristics of denture thermoplastic resins for non-metal clasp dentures. Dent Mater J 2010;29(4):353-61.

13. Hamanaka I, Takahashi Y, Shimizu H. Mechanical properties of injection-molded thermoplastic denture base Resins. Acta Odontol Scand 2011;69: 75-9.

14. Takahasi Y, Chai J, Kawaguchi M. Effect of water sorption on the resistance to plastic deformation of a denture base material relined with four different denture reline materials.Int J Prosthodont 1998;11(1):49-54.

15. Tham WL, Chow WS, Ishak ZAM. Simulated body fluid and water absorption effects on poly (methyl methacrylate)/ hydroxyapatite denture base composites. eXPRESS Polymer Letters 2010;4:517-28.

16. Dogan A, Bek B, Cevik NN, Usanmaz A. The effect of preparation conditions of acrylic denture base materials on the level of residual monomer, mechanical properties and water absorption. J Dent 1995;23(5):313-8.

17. Pronych GJ, Sutow EJ, Sykora O. Dimensional stability and dehydration of a thermoplastic polycarbonate-based and two PMMA-based denture resins. J Oral Rehabil 2003;30(12):1157-61.

18. Takahashi H, Kawada E, Tamaki Y, Teraoka F, Hosoi T, Yoshida T. Basic properties of thermoplastic resins for denture base material referred to “non clasp denture”. J J Dent Mater 2009;28:161-7.

|