Introduction

The denture base is subjected to various stresses during function. In order to withstand these, denture base should possess good mechanical properties[1]. In prosthodontic literature, palatal shapes have been classified according to cross-arch forms and categorized as ‘V’ shaped, ‘U’ shaped, flat or high, medium, low, rounded or combinations of it[2]. Nichols described the vault form in the edentulous maxilla as tapering, square, arched or flat[3]. Palatal vault shape influences the fracture strength of heat polymerized acrylic resin denture base which further helps it to bear the load [4]. Objective of this study was to investigate the flexural strength of three different high impact acrylic resin denture base materials in different palatal vault configurations.

Materials and Methods

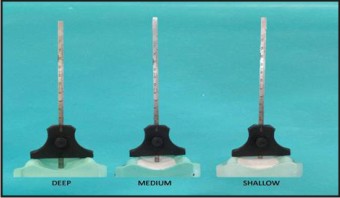

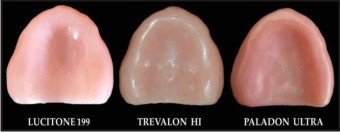

Three different high impact heat cure denture base materials i.e. Lucitone 199 (Dentsply), Trevalon Hi (Dentsply) and Paladon Ultra (Heraeus Kulzer) were used in this study for evaluation and comparison of flexural strength in three different palatal vault configurations. Three different palatal vault configurations chosen in this study were based on the method suggested by Johnson et al using custom made depth gauge[5]. His classification of casts based on palatal vault depth is as follows:

- Shallow or flat palatal vault depth i.e. less than ¼ inch.

- Medium palatal vault depth i.e. between ¼ inch and ½ inch.

- Deep palatal vault depth i.e. more than ½ inch.

Based on the classification (Fig.1), an edentulous cast with deep palatal vault was selected and duplicated using reversible hydrocolloid (agar) and two more casts were obtained. Plaster and pumice mix were added only in the deep part of palatal surface area, to modify these casts into medium and shallow palatal vault casts and were verified and finalized according to the Johnson’s classification, thereby maintaining the ridge configuration as a standard with the change only in the palatal depth and surface (Fig.2). Silicone molds were then made from these shallow, medium and deep palatal vault casts, using silicone duplicating material (Dow corning).

| Fig 1 : Deep Cast More Than 1/2 Inch. Medium Cast Between 1/4 And 1/2 Inch, Shallow Cast Less Than 1/4 Inch.

|

| Fig 2 : Deep Palatal Vault Casts Modified Into Medium And Shallow Casts

|

These molds were poured in dental stone to obtain thirty six casts of each type of palatal vault. These were grouped as A - Deep palatal vault cast, B-Medium palatal vault cast and C – Shallow palatal vault cast. Three casts with deep palatal vault were obtained from silicone mold. A uniform layer of 2mm modelling wax sheet was adapted on to the casts. The thickness of the wax was verified using the calibrated periodontal probe so as to have control over thickness of denture base. The patterns were invested, dewaxed and packed with heat cure clear acrylic resin (DPI) and processed. Acrylization was done using the short curing cycle at 74I0;C for 1 ½ hrs then at 100I0;C for 30 minutes in the electrical acrylizer. Bench cooling was carried out for first 30 minutes in air and then in water for next 15 minutes. After deflasking, the permanent three denture bases were retreived and the thickness of permanent denture bases were verified.

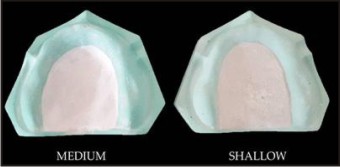

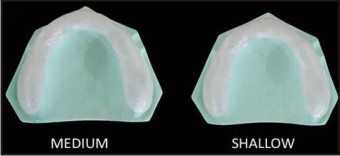

Out of the three denture bases obtained, one was utilized for making the deep palatal vault denture base, however, the other two denture bases were modified to fabricate medium and shallow palatal vault denture bases. The denture bases were trimmed and windows were made on the palatal part. These denture bases were placed on medium and shallow casts respectively (Fig.3). The wax up of window was done using 2mm modelling wax sheet (Fig.4). This was followed by flasking and processing in similar manner, thereby maintaining the configuration and thickness of the ridge area. As a result, three master denture bases (deep, medium and shallow) were fabricated. These respective denture bases were used to fabricate the test specimens of each palatal vault type.

| Fig 3 : Window Created On Denture Base And Seated On Medium And Shallow Casts.

|

| Fig 4 : Waxed Up Window In Palatal Portion

|

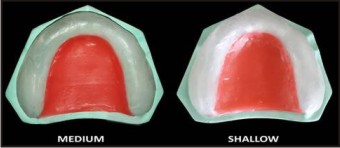

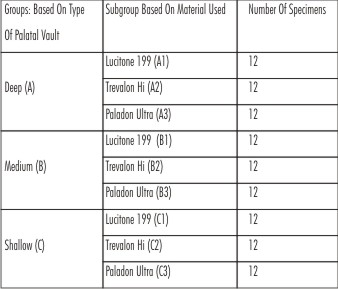

Individual test casts with their respective denture bases were flasked on their respective casts and invested. Thus, denture bases were fabricated such that 36 samples of deep palatal vault type were obtained with 12 each of Lucitone 199, Trevalon Hi and Paladon Ultra and were labelled as Subgroup A1, Subgroup A2, Subgroup A3 respectively. The master denture bases for medium and shallow palatal vault were similarly flasked along with their respective casts, processed and fabricated in similar manner. Thus, 12 test specimens each of Lucitone 199, Trevalon Hi and Paladon Ultra were fabricated resulting in a total of 36 specimens of medium palatal vault and 36 specimens of shallow palatal vault. They were named as Subgroup B1, B2, B3 and Subgroup C1, C2, C3 respectively. The 108 specimens thus obtained were verified for thickness. Finishing and polishing was carried out in a conventional manner. These specimens obtained were grouped and stored in water at room temperature for 48 hours (Fig.5)

| Fig 5 : Denture Bases

|

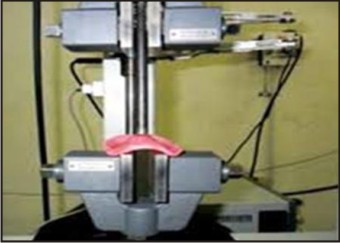

The prepared 108 high impact denture bases were tested for fracture energy on the Universal Testing Machine. The specimens were placed on the universal testing machine platform such that the polished surface was facing downwards. The fracture energy of the specimen was determined using 3-point bend testing (Fig.6). The device consisted of a loading wedge and a pair of adjustable supporting wedges placed apart. A round plunger of diameter 5mm was placed in midline on the most prominent point of palate. The load in compression was gradually applied at the rate of 5mm/min to the tissue surface.

| `Fig 6 : Universal Testing Machine

|

On testing, two vital parameters were obtained i.e. the load to which the denture bases fracture in Kilograms (Fracture load) and the amount of deflection before fracture in centimeters (Fracture deflection)[6].Using these two parameters, third parameter i.e. fracture energy was calculated using the standard formula:

Fracture energy (kg/cm) = ½ x Fracture Load (in kg) x Deflection (in cm) at the time of fracture. The fracture energy readings were obtained, mean values were calculated and subjected to statistical analysis using One way ANOVA test and Post-hoc Bonferroni test.

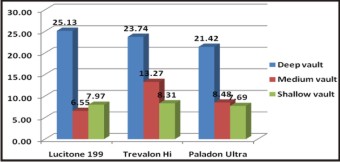

| Fig 7 : Comparison Of Mean Fracture Energy Of Denture Bases Made With Different Materials On Different Palatal Vaults

|

Results

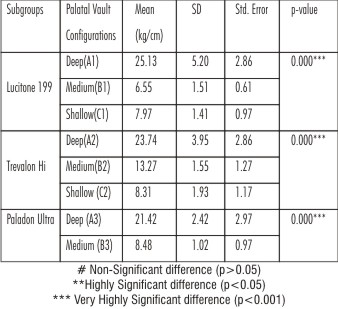

Table 1 shows the comparison of mean fracture energies of denture bases made on different palatal vault configurations (One way ANOVA test). Deep palate denture bases (Group A) showed the maximum fracture energy and shallow palate denture bases (Group C) showed the minimum fracture energy, irrespective of the material used.

| Fig 8 : Comparison Of Mean Fracture Energy Of Denture Bases Made With Different Materials

|

Figure 7 shows the comparison of mean difference of fracture energy amongst denture bases made on different palatal vault configurations. The mean difference of fracture energy between medium and shallow palates was not significant. However, their fracture energy when compared with deep palate was highly significant.

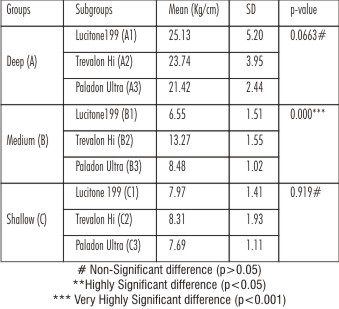

| Groups And Subgroups

|

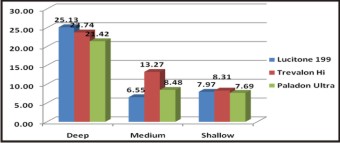

Table 2 shows the comparison of mean fracture energies of denture bases made with different materials (One way ANOVA test). Denture bases made with Trevalon Hi showed highest fracture energy when compared to the denture bases made with Lucitone 199 and Paladon Ultra.

| Table-1 Comparison Of Mean Fracture Energy Of Denture Bases Made On Different Palatal Vaults. (One Way Anova Test)

|

Figure 8 depicts the comparison of mean difference of fracture energies amongst denture bases made with different materials (Post hoc bonferroni test). It can be inferred that the mean difference of fracture energies is highly significant between Lucitone 199 and Trevalon Hi for medium palate samples (Group B).

| Table-2 Comparison Of Mean Fracture Energy Of Denture Bases Made With Different Materials (One Way Anova Test)

|

On the basis of the results obtained the denture bases made on deep palatal vault had the best flexural strength as compared to the denture bases made on medium and shallow palatal vault. Also, it can be inferred that the denture bases made with Trevalon Hi had the best flexural strength.

Discussion

The denture base is that part of the denture which rests on the soft tissues and does not include the artificial teeth. Since denture base materials must withstand forces during function and while in service, the mechanical properties are very important[7]. In our study we tested three different depths of the palatal vault because the depth of the palate may have a role in distribution of stresses that occur during functional and parafunctional movements of the jaw. The results of this study indicate that the flexural strength of shallow palatal vault is less when compared to medium and deep palatal vault and deep palatal vault had better flexural strength compared to medium palatal vault. The most probable reason for this is that in patients with deep palatal vault, the height of contour in the anterior part of the palate, may act as secondary stress bearing area which may help in dissipating forces acting on the denture base whereas in case of flat palatal vault, there is downward extension in the posterior part of the palate but there is no counteracting force dissipation effect by anterior slope of palate[8].

Also, the reason for different flexural strength of different palatal vault could be as suggested by Schneider that the fulcrum created in a denture at the mid palatal suture contribute to variation in resistance of the denture bases to fracture in different palatal vault configurations[9],[10].

Various feasible solutions to the complication of fracture in the shallow palatal vault bases are:

- Using glass fibers to reduce the acrylic resin fracture problems

- Use of metal bases

- Eliminating occlusal interferences and establishing balanced occlusion

- It can also be avoided by the application of prosthodontic principles during denture construction. The principles include even and adequate bulk of denture base material cured to achieve optimum polymerization, free of porosity, relief of incompressible tissue in the center of the hard palate, addition of labial flange to increase rigidity of denture base as well[11].

The second objective of our study was to compare the flexural strength of three different high impact heat cure denture base materials i.e. (i) Trevalon Hi (Dentsply), which mainly contains PMMA and are reinforced with n- BMA, (ii) Paladon ultra (Heraeus Kulzer), which mainly comprises of methyl methacrylate copolymer, impact modifiers and is cadmium free and (iii) Lucitone 199 (Dentsply), is PMMA with rubber reinforced high impact denture base resins.Lucitone 199(Dentsply), Trevalon Hi(Dentsply) and Paladon Ultra(Heareus Kulzer). The present study showed that there is significant difference between the three high impact acrylic resin denture base materials and the results of mean energy to fracture, in our study showed that Trevalon Hi had better flexural strength than Lucitone 199 and Paladon Ultra. The p-value obtained was <0.001. This indicated highly significant difference between the three high impact heat cure denture base materials.

The strength of acrylic polymers can be improved significantly by the incorporation of acrylic copolymers such as n-butyl methacrylate (n-BMA). The copolymer is able to absorb energy and thus protect the acrylic resin from fracture. This explains the highest fracture strength of n-BMA reinforced PMMA[12]. From all the comparisons, our study showed that the depth of palatal vault and the type of high impact heat cure resin significantly affect the fracture resistance of denture bases.

Conclusion

Based on the above observations, statistically analyzed and discussed, the following conclusions can be drawn:

1. The denture bases fabricated on deep palatal vault had the best flexural strength and denture bases on shallow palatal vault had the least.

2. n-BMA reinforced PMMA (Trevalon Hi) showed better resistance to fracture in all the palatal vault configurations.

Acknowledgement

We are very thankful to Mr. R.K, Singh, Professor, Mechanical Department , Central Scientific Institute of Plastics and Engineering, Murthal, Haryana for his whole hearted involvement and excellent guidance at every stages of this research project.

References

1. Alla RA, Sajjan S, Alluri VR, Ginjupalli K, Upadhya N.Influence of Fiber Reinforcement on the Properties of Denture Base Resins. Journal of Biomaterials and Nanobiotechnology 2013; 4: 91-97.

2. Heartwel CM, Rahn AO.Textbook of Complete Dentures .ed 2 1974,p117.

3. Nichols IG. Prosthetic dentistry. St.louis C. V. Mosby Co, 1930, p102.

4. Park SE, Chao M, Raj PA. Mechanical properties of surface charged poly methyl methacrylate as denture resins. International journal of dentistry 2009; 1-6.

5. Johnson DL, Holt RA, Dunconson MG Jr. Contours of edentulous palate. J Am Dent Assoc. 1986;113: 35-40.

6. Sowmya S, Dhakshaini MR, Gujjari AK, Ravi MB, Swamy KN. Palatal vault depth influence on the flexural strength of two heat cure acrylic denture base resins-an in vitro comparative study. World Applied Sciences Journal 2013; 21(9):1290-4.

7. Darbur UR, Huggett R,Harrison A. Stress analysis technique in complete denture;22:259-264.

8. Saraf VR, Shetty V, Anandakrishna GN, Rairam SG. Comparison of mechanical strength of palatal denture bases made from three commercially available high impact acrylic resin denture base materials in different palatal vault configurations-an in vitro study. Journal of Oral Health Research 2013; 4(1): 1-7.

9. Schneider RL. Diagnosing functional complete denture fractures. J Prosthet Dent 1985; 54(6):809-814.

10. Meyer FS. Dentures-Causes of failures and remedies. J Prosthet Dent 1951;1:1951.

11. El-Sheikh AM, Al-Zahrani SB. Causes of denture fracture: A survey. Saudi dental journal 2006; 18(3):149-154.

12. Jagger DC, Harrison A, Jandt KD. The reinforcement of dentures. J Oral Rehabil. 1999; 26 (3):185–94.

|