Introduction

The success of complete dentures depends upon esthetics, comfort and function. Unfortunately the health of the supporting tissues may be adversely affected by high stress concentration during function. A number of denture wearers suffer from chronic soreness. As the mucosa is confined between hard denture base and the bone, damage can be done during normal function, resulting in chronic soreness, pathological changes and finally bone loss. Problems are even more pronounced in patients suffering from diabetes, other debilitating diseases and in geriatric patients. In order to overcome these adverse effects use of soft lining material is advocated with the intention to distribute functional and parafunctional stresses more evenly and to provide a R19;cushioning effect’ to the mucosa to act as a R19;shock absorber’ because of its elastic behavior. This property of soft denture lining material makes it especially useful for treating patients with ridge atrophy or resorption, bony undercuts, clenching tendency, congenital or oral defects requiring obturator, xerostomia and dentures opposing natural dentition.

The first synthetic resin developed in 1945 as a soft liner was a plasticized polyvinyl resin, followed by the introduction of silicones in 1958.[1] Soft liners are applied to tissue surface of the denture to condition abused tissues underlying ill-fitting dentures, record functional impressions, and provisionally reline ill-fitting dentures and immediate dentures. The most effective materials used as liners are methyl methacrylate copolymers, plasticized polyvinyl chloride and more recently elastomers of the heat cured and self cured silicone type.[2] The desirable properties of resilient denture liners are long term resiliency, compatibility with oral tissues, dimensional stability, inhibition of fungal growth and good adhesion to denture base materials. But they have several inherent drawbacks associated with their use, such as loss of softness, colonization by Candida Albicans, porosity, poor strength, and adhesion failure between denture base and liner.[3]

The failure of the resilient liner is most often attributed to the loss of adhesion between resilient liner and Polymethyl methacrylate denture base due to lack of effective bonding. Debonding of soft liner from denture is a common clinical occurrence and often causes functional failure of prosthesis. Bond failure also creates potential surface for bacterial growth, plaque accumulation and calculus formation. Several efforts in the past have been made to increase the strength and longevity of the bond between Polymethyl methacrylate denture base and the resilient liner with varying results. Various studies have shown that properties of material change with time and with the material losing its resilience and also getting deboned from Polymethyl methacrylate base. This necessitates frequent replacements. Handling of the denture resilient liners may influence the serviceability. One factor that could influence the length of service could be soaking of dentures in the cleanser compared to immersion in water when not in use. Very few studies have addressed the effects of denture cleanser on soft liners.

So, the present in-vitro study was conducted to evaluate changes in tensile bond strength of resilient liners bonded to acrylic resin when immersed in a denture cleanser as compared to the immersion in distilled water. Further, to simulate the oral environment and actual storage conditions, alternate immersion in artificial saliva and denture cleanser was done as compared to immersion in artificial saliva and distilled water.

Materials & Methods

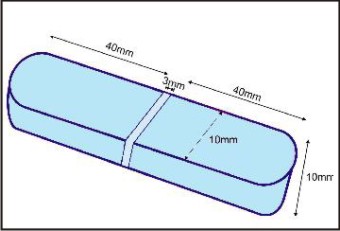

A total of 100 test specimens were prepared for the purpose of testing tensile bond strength. Each specimen (Figure 1) had dimensions of 83×10×10mms and consisted of two Polymethyl methacrylate blocks of dimensions 40×10×10 mm with a soft liner of uniform thickness of 3mm interposed between them.The test specimens were divided into the following groups-GroupA- Ten specimens (control group) were kept in distilled water till tested,Group B-Thirty samples were kept in artificial saliva and distilled water alternately for 12 hrs daily till tested. The 10 specimens tested after 1 month were designated as B1 & another 10 tested after 3 months were designated as group B2. The remaining 10 specimens which were tested after 6 months comprised of group B3, Group C- Thirty samples which were kept in denture cleanser containing sodium perborate and artificial saliva alternately for 12 hrs daily till tested. The 10 specimens tested after 1 month were designated as C1 & another 10 tested after 3 months were designated as C2. The remaining 10 specimens which were tested after 6 months comprised of groups C3, GroupD-Thirty specimens were kept in sodium hypochlorite 5% and artificial saliva alternately for 12 hrs daily till tested. The 10 specimens tested after 1 month were designated as D1 & another 10 tested after 3 months were designated as D2. The remaining 10 specimens which were tested after 6 months comprised of group D.

| Image 1

|

Preparation Of Artificial Saliva

Artificial saliva was prepared using the following ingredients: Sodium carboxymethylcellulose, Potassium chloride, Sodium chloride, Magnesium chloride, Calcium chloride, Di-potassium hydrogen orthophosphate, Potassium di-hydrogen orthophosphate, Sodium fluoride, Sorbitol, Methyl p-hydroxybenzoate, Spirit of lemon[4]

The Special Metal Die

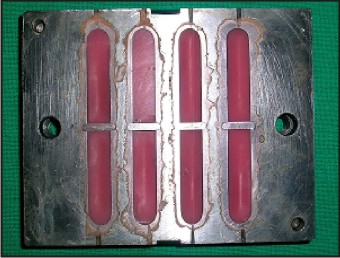

In order to have the specimens of identical shape and size, special die was prepared, which was made up of stainless steel. (Figure 2)

| Image 2

|

Preparation of test specimens

It was carried out in two stages:- A) Preparation of Polymethyl methacrylate blocks B) Addition of soft liner

A) Preparation of Polymethyl methacrylate blocks

For the purpose of testing of tensile bond strength, suitable specimens were prepared using stainless steel die. Polymethyl methacrylate polymer & Methyl methacrylate monomer were mixed according to manufacturer’s instructions in a porcelain jar. Once the mix reached the dough stage, it was packed in the moulds. The die was kept under slowly increasing pressure in a hydraulic press.After trial closure, flash was removed and the die was closed. Polymerization was carried out at 74º C for 8 hours followed by boiling for 1 hour in an acrylizer. The die was allowed to cool to room temperature, and then the die was opened and the blocks were removed from the metal mould. Any sharp edges of acrylic resin were smoothened. The blocks were measured by a digital caliper to ensure that all blocks had same dimensions. A total of 200 Polymethyl methacrylate blocks were prepared in this manner & paired comprising one left and one right block to get 100 pairs.

B) Addition of soft liner

Permanent soft liner was manipulated according to manufacturer’s instructions and placed in the 3mm space between the two Polymethyl methacrylate blocks previously occupied by the metal separator. The liner was then cured in boiling water at 100º C for 15 minutes. After curing, the metal die was allowed to cool at room temperature and then it was opened and specimen removed. Test specimens were placed in a stainless steel tray with ice cold water to temporarily harden the liner to facilitate removal of any excess using B P knife. Thus a total of 100 test specimens having a thickness of 3x10x10mm of soft liner between Polymethyl methacrylate blocks of dimensions 40x10x10mm were obtained. So all the 100 specimens had the same dimensions of 83x10x10mm.

Testing of Specimens

All the specimens were tested for tensile bond strength on Universal Testing Machine. The specimen was gripped vertically and firmly between upper and lower crosshead jaws of the machine. Then tensile force was applied gradually at a crosshead speed of 5mm/minute until complete debonding occurred. All the specimens were tested in a similar manner and the readings were recorded. Tensile bond strength was calculated by the formula:-

TENSILE BOND STRENGTH = FORCE AT DEBONDING

---------------------------------------

CROSS-SECTIONAL AREA OF THE INTERFACE

The values were recorded in kg/square cm.

Results

The findings were compared analyzed and subjected to statistical analysis, which was carried out by using SPSS software 16.5 version.

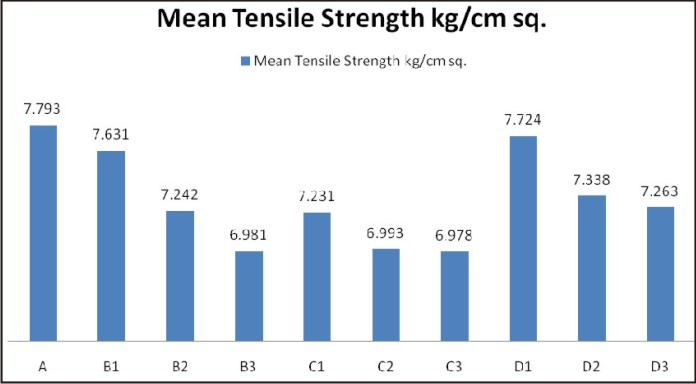

The mean tensile strength (Graph 1) for Group A(specimens stored in distilled water) was recorded as 7.793 kg/cm sq whereas for Group B1(specimens stored in artificial saliva & tested after 1 month) was recorded as 7.631 kg/cm sq, for group B2(specimens stored in artificial saliva & tested after 3 months) was 7.242 kg/cm sq, B3(specimens stored in artificial saliva & tested after 6 months) was 6.981kg/cm sq. Tensile bond strength of group C1(specimens stored in cleanser with sodium perborate after 1 month) was 7.231 kg/cm sq, for C2(specimens stored in cleanser with sodium perborate after 3 months) was 6.993 kg/cm sq, for C3(specimens stored in cleanser with sodium perborate after 6 months) was 6.978 kg/cm sq. Tensile bond strength of group D1(specimens stored in cleanser with sodium hypochlorite after 1 month) was 7.724 kg/cm sq, for D2(specimens stored in cleanser with sodium hypochlorite after 3 months) was 7.338 kg/cm sq, & for D3(specimens stored in cleanser with sodium hypochlorite after 6 months) was 7.263 kg/cm sq. The highest tensile bond strength of permanent soft liner to Polymethyl methacrylate was observed in group in A and lowest tensile bond strength value with group C3.

While comparing bond strength of permanent soft liner to Polymethyl methacrylate between different test groups, it was seen that a significant difference was observed in the tensile bond strength when specimens were tested after 3 months & 6 months between all the test groups (p<0.01), whereas this difference was not significant when tested after 1 month (p>0.01).Also,when the correlation was studied between the different experimental groups, no significant difference was seen(p>0.01). This shows that the denture cleansers sodium hypochlorite or sodium perborate don’t have any deleterious effect on the bond strength of the permanent soft liner to Polymethyl methacrylate.

| Graph 1

|

Discussion

Resilient lining materials are products that are applied to the tissue surface of dentures for the purpose of achieving a more equal distribution of the load and thereby avoiding excess pressure points which could result in tissue soreness and eventually ridge resorption.

One of the first synthetic resins used as a resilient liner, a plasticized polyvinyl resin was developed in 1945.[1] Silicone- based materials were introduced in 1958. Resilient liners can be categorized basically into Temporary soft liners and Permanent Soft liners. The temporary soft liners are given to bring abused tissue to a condition of health. These are auto polymerized resins and are used for a relatively short period of time i.e. few days. These are called tissue conditioners or short term liners. The permanent soft liners are intended to function for a much longer period ranging from 6 months to 5 years. They are intended to act as shock absorber in areas of excessive loading and thus contribute towards tissue preservation by preventing excessive pressure and thereby enhancing comfort. They are heat processed to a hard resin base. They are also called long term soft liners.

Permanent resilient liners can be categorized according to their chemical structure as plasticized acrylic resin, vinyl resins, polyurethane and phosphazine rubbers and silicon rubbers. Contemporary resilient liner materials can be divided into 2 groups acrylic resin- based and silicone based.[5] The most commonly used soft liners are plasticized acrylic resin. They are available as powder/ liquid systems. Powder consists of methylmethacrylate polymer and co polymer. Liquid consists of methacrylate monomer and plasticizer, (ethyl alcohol or phthalate).

Silicon based resilient liners are similar in composition to silicon type impression materials as they are dimethyl siloxane polymers. Poly dimethyl siloxane is a viscous liquid that can be cross linked to form an elastic rubber. No plasticizer is necessary to produce a softening effect with this material.[6]

The soft liners undergo deterioration while in use, either by the leaching out of plasticizer and other soluble materials or by absorption of watery contents of saliva. This eventually affects its bond with the denture base. The initial softness of the plasticized acrylic resin results from the plasticizer which acts by lowering the glass transition temperature of the polymer to a value below mouth temperature so that the modulus of elasticity of the resilient material is reduced to a satisfactory level.[6]

The efficacy and longevity of these materials in service depends on whether they exhibit most of the desirable properties i.e. biocompatibility, good adhesion but no adverse effects on the denture base, dimensional stability, permanent resiliency, no water absorption, color stability, high abrasive resistance and ease of maintainence.

The permanent resilient liner can be used as an adjunct in treatment of chronic denture soreness in situations like ridge atrophy or resorption, contraindicated surgery, relief areas, restoration of congenital or acquired defects, post irradiation, bony undercuts, bruxing tendencies, xerostomia and dentures opposing natural dentition in opposing arch. An effective bonding between denture base and lining material is of paramount importance. One of the major drawbacks of the permanent soft liners is the lack of durable bonding to denture. Debonding of soft liners from the denture is a frustrating experience both for the patient and the clinician as it results in localized unhygienic conditions at deboned region and often results in functional failure of prosthesis. Bond failure also creates a favorable surface for bacterial growth, plaque accumulation and calculus formation. For this purpose the storing of dentures in cleanser containing sodium perborate or sodium hypochlorite has been advocated. This study was undertaken to investigate the effect of cleanser on the tensile bond strength of Permasoft permanent soft liners to Polymethyl methacrylate resin.

The results of present study showedthat the mean tensile strength was highest for Group A and lowest for Group C3. In the pair wise comparison, the difference in the bond strength of permasoft permanent soft liner & Polymethyl methacrylate was statistically insignificant when group B1 was compared with group C1. However, when group B2 was compared with C2 & group B3 was compared with C3, it showed significant difference. When the comparison was done between C1 & D1, no significant difference was observed. However significant difference was observed when comparison was done between C2, D2 & C3, and D3.

Also, when the correlation was studied between the different experimental groups, that is between B1 & C1, B2 & C2, B3 & C3, C1 & D1, C2 & D2, C3 & D3, B1 & D1, B2 & D2, B3 & D3, no significant difference was seen. This shows that the denture cleansers sodium hypochlorite or sodium perborate do not have any deleterious effect on the bond strength of the permanent soft liner to Polymethyl methacrylate.

Garcia[7] observed that the effect of denture cleanser tested (Polident), when compared with water, did not cause significant changes in the tensile bond strength and surface roughness of the two resilient liners for the time period tested and also found that specimens immersed in artificial saliva compared with distilled water, tensile bond strength was unaffected. A Mese[8] observed that cleansers tested, when compared with water, did not cause significant changes in the tensile bond strength of the four soft denture lining materials for the time period tested.

It was said by Kutay O et al[9] that sufficient bond strength of 4.5 kg/cm² between the soft denture lining and the acrylic resin denture base material is required to avoid interfacial separation at the denture borders. In the present study the average bond strength for different groups ranged between 7.793 kg/cm2 to 6.978 kg/cm2. This figure is much higher than 4.5 kg/cm2. This means that the storage of denture in denture cleanser containing sodium perborate & sodium hypochlorite does not adversely affect the bond strength.

The present study was carried out for the period of 6 months during which no significant decrease in bond strength was observed irrespective of the fact whether the specimens were stored in artificial saliva or denture cleanser containing sodium perborate or sodium hypochlorite. Further, denture cleansers can be effectively used without causing any adverse effect on the tensile bond strength for a period of 6 months.

However, further studies are required to evaluate the usefulness of the resilient liners for a longer period of time as the manufactures of soft liner claim that usefulness is for a period of five years.

References

1. El-Hadary A, Drummond JL. Comparative study of water sorption, solubility, and tensile bond strength of two soft lining materials. J Prosthet Dent 2000;83:356-61 (cited in Ayse Mese. J Prosthet Dent 2008;99:153-159)

2. Duygu Sarac,Y. Sinasi Sarac. Evaluation of microleakage and bond strength of a silicon based resilient liner following denture base surface pretreatment. J Prosthet Dent 2006;95:143-151

3. Yasemin Kulak-Ozkan, Atilla Sertgoz and Hale Gedik. Effect of thermocycling on tensile bond strength of six silicone-based, resilient denture liners. J Prosthet Dent 2003;89:303-310

4. A. Preetha, R. Banerjee. Comparison of artificial saliva substitutes. Trends Biomater Artif. Organs 2005; 18(2): 178-186

5. Polyzois GL, Frangou Mj. Influence of curing method, sealer, and water storage on the hardness of a soft lining material over time. J Prosthodont 2001; 10: 42-5(cited in Ayse Mese 2008)

6. Qudah S, Huggett R, Harrison A. The effect of themocycling on the hardness of soft lining materials.Quintessence Int 1991; 22: 575-80 (cited in Jose Renato Ribeiro Pinto. J Prosthet Dent 2002;88: 516-521)

7. Renata C.M Rodrigues Garcia, Blanca L.T Léon, Viviane M.B Oliveira, Altair A Del Bel Cury. Effect of a denture cleanser on weight, surface roughness, and tensile bond strength of two resilient denture liners. J Prosthet Dent 2003; 89: 489-494

8. A. Mese. Bond strength of soft denture linersfollowing immersion of denture cleanser.Biotechnol. & biotechnol. eq 20/2006/3 184

9. Omer Kutay.Comparison of tensile and peel bond strengths of resilient liners. J Prosthet Dent 1994; 71: 525-531

|