Introduction :

Direct bonding of orthodontic brackets, since its introduction by George V Newman[4], dramatically improved the clinical practice of orthodontics.The pioneering work of Bunocore[1], Bowen[2] and Tavas[3] yielded an array of materials which have become an integral part of orthodontic bonding. However the process of bonding is technique sensitive and moisture contamination is considered the most common reason for bond failure[6]. A reduction in bond strength of resins to etched enamel after moisture and saliva contamination has been reported by several researchers [7] ,[8] , [9].

The fifth generation bonding systems were developed to minimize the steps in bonding and increase the reliability of bonding in moist environment[6]. This moisture resistant adhesive is available in a primer formulation that replaces the conventional bonding agent applied to the etched enamel and consists of an aqueous solution of methacrylate-functionalized polyalkenoic acid co-polymer and hydroxyethyl-methacrylate. This product has originally been used as a hydrophilic primer in dentine bonding systems marketed by the same manufacturer ( 3M Unitek)[7].

In an effort to enhance the quality of the adhesive system and to save chair side time and to perform faster and easier bonding procedures, the light-cured, adhesive- precoated brackets (APC, 3M Unitek) were introduced in 1992. Precoating the brackets necessitated modifications in the composition of the adhesive more specifically the viscosity of the adhesive was reduced in order to facilitate the accurate placement of the precoated bracket on the tooth by the clinician, without having to use excessive pressure on the tooth. Third generation precoated brackets with fluoride releasing and better moisture tolerant properties were introduced in 2004[10] (APC Plus).

The use of precoated brackets with a moisture insensitive bonding agent will be a definite advantage in clinical practice which will facilitate bonding in moist environment and also reduce steps in bonding, thereby saving chair-side time.

Hence, the present invitro study investigated the bond strength of metallic brackets bonded Transbond XT with MIP and adhesive precoated brackets ( APC plus) brackets bonded with MIP under moist conditions and compared them to conventional composite bonding material- Transbond XT with Transbond XT primer bonded under dry condition.

The present study would also evaluate if change in adhesive composition would significantly affect the bond strength as the adhesive used to precoat the metal brackets in APC Plus brackets essentially differ in the filler content.

Materials and methods:

Fox et al[11](1994) presented critical review of 66 publications on orthodontic bond strength testing and suggested a detailed protocol for future bond strength testing in orthodontics. Their criteria were taken into account when the protocol for the present in-vitro study was developed .

For the purpose of the study, 90 maxillary premolars extracted as a part of orthodontic treatment were collected and the teeth were non carious, unrestored and with no enamel cracks and not previously chemically treated and were debrided and stored in normal saline solution at room temperature.The time elapsed between the extraction and the bonding experiment was less than 6 months.

The teeth were randomly divided into three groups of thirty each, to be tested using different adhesive primer combination.

The teeth were sectioned using a straight fissure bur on aerotor hand piece at two thirds the root length (to facilitate mounting) and were mounted in cold cure acrylic blocks in three different colors – clear, red, and green, of diameter 23mm using alginate impression of metal ring, such that the buccal surface was exposed parallel and slightly above the rim of the impression.The mounted teeth were stored in normal saline till bond strength testing was done.

The brackets used for testing were Gemini series maxillary premolar brackets – Roth prescription and 022 slot(3M Unitek) and adhesive precoated Victory series low profile maxillary premolar brackets - MBT prescription and 022 slot brackets- APC Plus brackets(3M Unitek). All the brackets have similar bracket base (mesh base) design.

For all groups, the teeth were rinsed under tap water and cleaned with oil free, non fluoridated pumice using micromotor and rinsed and dried with chip-blower. Etching was done with 37% orthophosphoric acid gel etchant (Viscous Etch, Orthosource) for 30 seconds. The teeth were then rinsed and dried using absolute alcohol + acetone solution (dehydrating agent)until the buccal surfaces of the etched teeth appeared to be chalky white in color.Brackets were bonded on the buccal surfaces according to the instructions supplied by the manufacturer of each product.

Bonding procedure:

Group I : Athin coat of Transbond XT primer was applied using an applicator tip and light cured for 5 seconds. Brackets were placed onto the centre of the tooth, parallel to the long axis, with Transbond XT on the base of the bracket. After the bracket was properly positioned on the tooth, each bracket was subjected to 300 grams of force using a force gauge (Dontrix gauge) for 10 seconds and excess bonding resin was removed using a small scaler. The adhesive was light cured using SmartLite PS ( DENSPLY, Germany) with a 5 W light emitting diode with average light intensity of 950mW/sqcm and wavelength of 450 – 490 nm (intensity maximum at 460nm), for 20 seconds according to manufacturer’s instructions. All the brackets are mesh based and similar in bracket base design.

Group II: MIP : After pumicing and etching like in group I, the bonding surface was wet with two coats of distilled water and then MIP primer was applied and then bonding (with Transbond XT ) and curing was done similar to that of control group.

Group III : APC Plus : After pumicing and etching and wetting the bonding surface like in group II, Adhesive Precoated Brackets (APC plus) were positioned and force of 300 gms for 10 seconds was applied using force gauge (Dontrix gauge) and excess bonding resin was removed using a small scaler. The adhesive was light cured using SmartLite PS (DENSPLY, Germany).

After bonding, all the specimens were stored in distilled water for one hour, at room temperature, before the shear bond strength testing was done.

Bracket Surface Area Measurement:

The bracket surface area is measured by micrometric analysis using an eye piece reticle and objective lens of 2.5 X magnification, on a light microscope (Leitz, Germany) and calculated to be 9.71 sqmm for APC Plus brackets and 10.80 sqmm for Gemini series brackets.The different bracket base areas do not affect the comparisons as the effective bond strength in MPa is being compared which includes the bracket surface area.

Bond Strength Testing:

Shear bond strength testing was done with the INSTRON Universal Testing machine (Model 4206). The machine was set and calibrated according to manufacturer’s instructions. The acrylic block with embedded tooth and bonded bracket were positioned in the jig to ensure that the bracket edge corresponding to occlusal edge was always the site where load was applied. The steel plunger was used to apply load at the bracket adhesive interface. The brackets were shear tested for failure using a load cell of 500 N and a cross head speed of 1 mm/min.

The debonding force was recorded in kilograms by the computer and it was converted into bond strength (force per unit area) by the following formula:

Bond strength =

Debonding force (kgs) X 9.81

Bracket surface area

Site Of Bond Failure :

The site of bond failure is determined from the adhesive remnant index scoring. Each of the tested specimens was observed under a stereomicroscope (Leitz, Germany) with magnification of 10 X and scoring was given according to the modified adhesive remnant index[12].

Score 5 - no composite remaining on the enamel

Score 4 - less than 10% of composite remaining on the tooth surface

Score 3 - more than 10% but less than 90% of composite remaining on the tooth

Score 2 - more than 90% of composite remaining on the enamel

Score 1- all composite remaining on the tooth, along with the impression of the bracket base.

All the values recorded were tabulated and statistically tested.

Statistical Analysis :

The test statistics was performed using statistical package for social sciences(SPSS VERSION 13). Descriptive statistics were calculated for each group of teeth tested. Analysis of Variance was used to determine if significant differences existed between the various groups compared. The Pearson chi-square test was used to identify any significant difference in the ARI score amongst the groups. Significance for all statistical tests was predetermined at P < 0.05.

As indicated by Fox et al[11], mean and S.D. may not be the best indicator for the performance of the material.as when considering bonding materials, the weaker values (the tail of the distribution) are of more importance and hence a survival analysis - Weibull analysis is performed to analyze the characteristic bond strength and the probability of failure for each of the material at given values of applied force. The Weibull distribution[13],[14] is a parametric test. It takes into account the tail values of a distribution. It is characterized by the Weibull modulus, which expresses the spread of the data, and the normalizing parameter or characteristic level, in this case the characteristic bond strength, which more or less corresponds with the mean bond strength for a Gaussian distribution. It can be characterized by the following equation which relates probability of failure (Pf) to applied stress (σ). The equation is:

Pf = 1- e {-( σ – σu / σ0 ) m

σu and σo are constants. σu is thelowest level of stress at which Pf approaches zero and is normally assumed to be equal to zero. σo is the normalizing parameter or characteristic level and is described by Fox et al as the characteristic strength. The higher the Weibull modulus, lesser reliable is the material and as the characteristic strength increases, the reliability increases.

Results :

In Group I , during the bond strength testing, two brackets deformed extensively on debonding,and with two specimens reading could not be obtained ( debonded at 0 newtons ) due to technical snag (improper circuit with the computer reading the force values) in the testing machine. hence these specimens were not included in the study. The mean and S.D. were computed for 26 specimens in group I (Table 1).

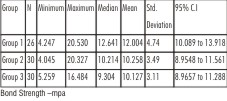

| Table I: Descriptive Statistics Of The Three Groups.

|

In the control group (group 1) the mean bond strength (MPa) was found to be 12.00 sd 4.74 MPa with a range of 4.24 MPa to 20.53 MPa (confidence interval of 10.09 to 13.92)

In the moisture insensitive group bonded with Transbond XT (group II) the mean bond strength observed was 10.26 sd 3.49 and the range is 4.04 MPa to 20.32 MPa. (Confidence interval of 8.95 to 11.56 )

In the adhesive precoated groups, group III – bonded with APC plus, the mean bond strengths observed were 10.13 sd 3.11 MPa and ranged from 5.26 MPa - 16.48 MPa (confidence interval of 8.97 to 11.29).

The ANOVA test was done to find if significant differences existed between the groups and it showed no statistical significant difference between the groups (p = 0.023).

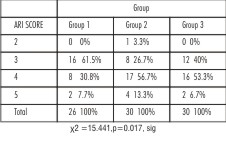

Table II shows the site of failure and the percentage of specimens having adhesive or cohesive failure and it shows that the bond failure was predominantly cohesive (within the adhesive material) in group I with 61.5% specimens showing an ARI score if 3, while groups II and III showed failure at enamel adhesive interface with 56.7% showing score of 4 in group II and 53.5 % in groups III.

| Table II: Adhesive Remanant Index Scoring In The Three Groups

|

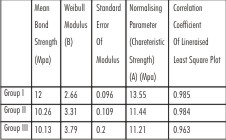

Table III shows the Weibull modulus of the materials tested in the four groups. Group III has the highest Weibull modulus of 3.79 and group I shows the lowest Weibull modulus of 2.66. The characteristic strength observed is highest for group I (13.55 MPa) and lowest for group III (11.21 MPa), and groups II shows characteristic strength values close to group III ( 11.44 MPa and 11.21 MPa respectively.) The correlation coefficient obtained is very high for all the groups ( > 0.95)

| Table III: Weibull Analysis

|

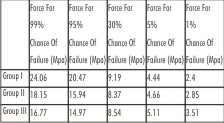

Table IV relates the probability of bond failure to applied stress. It can be seen that force for 99% chance of failure is highest for group 1 (24.06 MPa) and lowest for group III (16.77 MPa) – it means that group 1 can withstand higher force when compared to all other groups.

| Table IV: Force Required For Various Probabilities Of Failure

|

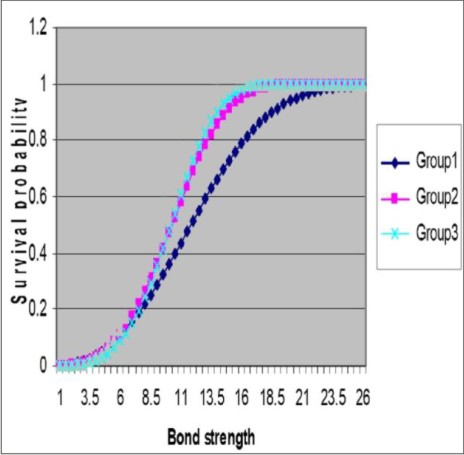

It can also be seen that at 1 – 5 % chance of failure, there is little difference between the groups. It can be seen graphically on fig.1 by the fact that the curves cross over each other in this region.

The Graph – representing the plot of Weibull curves on common axes (Fig 1) shows the curve by group I being displaced extremely to the right indicating that for these brackets, there would be a lower probability of debonding during treatment, and the curve by group II and group III overlap considerably

| Fig 1 :Weibull Graph

|

.

Discussion:

The results show that the bond strength values decrease in the order of

group 1 > group 2 > group 3 with mean bond strength values of 12.00sd4. 74 MPa, 10.26sd3.49, and 10.13sd3.11 respectively.

According to Reynolds[4], bond strengths of 5.9 to 7.8 MPa suffice for most clinical orthodontic needs, although it is unclear whether this refers to shear or tensile bond strength. The bond strength values obtained are higher than the values prescribed by Reynolds et al and hence suggest that these material combinations can be used successfully clinically.

The bond strength values of the conventional adhesive under dry condition is in accordance with the values obtained by Grandhi et al[16] (11.06 MPa), Schanwdevdt et al[18] (14.82 MPa), and Arndt Klocke et al (15.07 MPa.). However, the values are lower than that obtained by Webster et al[17] (26.1) and Hobson[15] (15.69 MPa) and higher than those obtained by Rajagopal et al [19] (9.57 MPa).

The bond strength values obtained for conventional adhesive with MIP in wet conditions is similar to those obtained by Hobson et al[15] (12.89 MPa ) and Grandhi et al[16] (9.69 MPa) ( after wetting the etched enamel surface with water), and Rajagopal et al[19] (9.07 MPa) (after wetting the etched enamel surface with saliva). Slightly higher bond strength values were seen with Schaneveldt et al[18] (14.02 MPa) (after wetting the etched enamel surface with water) and Arndt Klocke et al (14.91 MPa) and Webster et al[17] (21.9 MPa) (after wetting the etched enamel surface with saliva).

The adhesive precoated brackets APC Plus - demonstrated significant bond strengths in the present study.

By applying a layer of Transbond MIP to acid conditioned enamel, in addition to micromechanical retention, a reversible hydrolytic bond mechanism can be established by breaking and reforming of carboxylate salt complexes formed between the ionized carboxyl groups of the methacrylate functionalized-polyalkenoic acid copolymer and residual enamel calcium. This might enhance the bonding onto water-contaminated or saliva contaminated enamel surfaces.

The Weibull analysis also shows that uncoated brackets bonded with Transbond XT and Transbond primer in dry environment (control group) would perform better clinically with lesser bond failures than the other groups and the performance of the other twogroups is comparable and the reliability decreasing in the order of group II > group III.

It can be seen from Table IV that force for 99% chance of failure is highest for group 1 (24.06 MPa) and lowest for group III (14.76 MPa) – it means that group 1 can withstand higher force when compared to all other groups.

It can also be seen that at 1 – 5 % chance of failure, there is little difference between the groups. It can be seen graphically on Fig.1 by the fact that the curves cross over each other in this region.

If a bond failure rate of 5% is considered clinically acceptable, and if forces of around 5 MPa are experienced clinically, then group III – APC plus with MIP would be better in a clinical situation despite group I having higher mean bond strength. However the problem is that the stress applied in a clinical situation is very difficult to measure and varies throughout the mouth.

The ANOVA test was done to find if significant differences existed between the groups and it showed no statistical significant difference between the groups (p = 0.023 ).

In this study, MIP under moist conditions produced acceptable bond strength compared to conventional primer, as was reported by Ross Hobson[15], Grandhi etal[16], Schaneveldt etal[18], Arndt etal, Rajagopal etal[19]. The values obtained for group II are in agreement with previous studies that evaluated the shear the bond strength of conventional and hydrophilic primers on dry and contaminated (with distilled water and saliva) enamel by Arndt Klocke and Grandhi[16] and Rajagopal etal[19] (contamination with artificial saliva).

However this is not in agreement with Littlewood[19], Rix etal[22], Webster etal[17], Zeppieri[20] who showed that bond strength of moisture insensitive primer in wet conditions is significantly lower than conventional primer in dry environment.

Bishara etal[24](1997)found that precoated brackets have significantly lower bond strength than those obtained by Transbond XT on uncoated brackets. But Bishara etal[25] in 2002 studied the effects of modifying the adhesive composition of APC and APC II brackets on bond strength and found that it did not affect the shear bond strength.

The range of ARI scores clearly demonstrated that Transbond XT used in dry field showed a significantly greater frequency of bracket failure sites within the adhesive itself, but when used with MIP in moist environment, it debonded more frequently at the enamel- adhesive interface. This agreed with the results ofCaccifesta etal[26], Webster etal[17], and Rajagopal etal[19], the findings are probably due to the hydrophobic properties of the adhesive composite.

Regarding the percentage of area of adhesive remaining on tooth, MIP/ Transbond XTand MIP/APC Plus left significantly less adhesive than did conventional primer/Transbond XT. This implies a reduction in chair-side time spent on adhesive removal after debonding

Limitations : The bond strength values in all three groups compared favorably with Reynolds[4] minimal bond strength values. However, clinical conditions may significantly differ from an in vitro setting. It needs to be emphasized that this is an in vitro study and the test conditions have not been subjected to the rigors of the oral environment. Heat and humidity conditions of the oral cavity are highly variable. Because of the probable differences in in vivo and in vitro conditions, a direct comparison cannot be made with the findings of the present studies.

It must also be noted, that the use of the terms ‘moist’ or ‘wet’ implies the presence of water, whilst saliva or crevicular fluid are considered ‘contaminants’. Although the presence of water can be prevented by adopting moisture- control precautions during bonding procedures, the orthodontist is often faced with the problem of bonding in an environment with increased contamination risk from saliva.

Also, a continually increasing tensile or shear load applied to bonded brackets in the laboratory is not representative for the force applications that occur clinically. The type of debonding force in machines is not the same as the force applied in clinical debonding.Hence a direct comparison of the clinical performance of these materials is not suggested to be made from the results of this study and to obtain better clinical information, clinical trials of the materials is recommended.

Conclusions:

Following conclusions can be drawn from the present study:

1. Moisture insensitive primer with Transbond XT produced bond strength comparable with conventional adhesive Transbond XT and hence MIP can be effectively used to bond to enamel when isolation is a problem.

2. Adhesive precoated brackets – APC Plus produced bond strength comparable with Transbond XT and hence it can be used in combination with MIP in moist environment.

3. The change in the composition of the adhesive in APC Plus brackets did not significantly affect the bond strength of the material.

4. Transbond XT with conventional primer had predominantly cohesive failure within the adhesive, while the remaining three groups showed a failure at adhesive – enamel interface.

5. All the adhesives tested showed bond strength values higher than those recommended for clinical bonding.

The present study showed that MIP and APC plus brackets could be used successfully clinically under moisture sensitive conditions .

References:

1. Buonocore MG. A simple method of increasing the adhesion of acrylic filling materials to enamel surface. J. Dent. Res. 1955; 34:849-853.

2. Bowen RL. Adhesive bonding of various materials to hard tooth tissues V: The effect of a surface-active monomer on adhesion to diverse substrates. J Dent Res 1965; 44:1369-73.

3. Tavas A, Watts DC. Bonding of orthodontic brackets by transillumination of a light activated composite: an in vitro study. Br J Orthod 1979; 6:207-8.

4. Newman GV .Epoxy adhesives for orthodontic attachments: Progress report .Am J Orthod1965; 51:901-912

5. Reynolds IR: A Review of Direct Orthodontic Bonding. BJO 1975; 2:171-8.

6. Round table :Bonding: the panel: Leonard Gorelick, Lenn M Masunaga, Royce G Thomas, Bjorn U Zachrisson, JCO 1978 oct (695 - 714)

7. Gorelick L: Bonding – The state of the art. A National survey JCO 1979:13(1):39-53

8. Hormati AA, Fuller JL, Denehy GE: Effects of contamination and mechanical disturbance on the quality of acid etched enamel J Am Dent Assoc 1980;100:34-38 et al

9. Silverstone LM, Hicks MJ, Featherstone MJ; Oral fluid contamination of etched enamel surfaces : an SEM study: J Am Dent Assoc 1985 :110;329-332

10. 3M Unitek document - What Does Adhesive Innovation Mean to You? A History of the APCAdhesive Coated Appliance System by Armineh Khachatoorian, Marketing Product Manager, 3M Unitek

11. Fox N A, McCabe J F, Buckley J G : A critique of bond strength testing in orthodontics. BJO 1994: 21: 33–43

12. Årtun J, Bergland S 1984 Clinical trials with crystal growth conditioning as an alternative to acid-etch enamel pre-treatment. Am J Orthod85 : 333 – 340

13. Fox N A, McCabe J F, Gordon P H: Bond strengths of orthodontic bonding materials: an in-vitro study. BJO 1991,18: 125–130

14. McCabe J F, Carrick T E 1986 A statistical approach to the mechanical testing of dental materials. Dental Materials 2: 139–142.

15. Ross S. Hobson, Jan Ledvinka, and John G. Meechan: The effect of moisture and blood contamination on bond strength of a new orthodontic bonding material: Am J Orthod2001;120:54-7

16. Ram Kumar Grandhi, Combe EC, Speidel TM.: Shear bond strength of stainless steel orthodontic brackets with a moisture-insensitive primer :Am J Orthod2001;119:251-5

17. Mark J. Webster, Ram S. Nanda, Manville G. Duncanson, : The effect of saliva on shear bond strengths of hydrophilic bonding systems: Am J Orthod2001;119:54-8.

18. Shane Schaneveldt and Timothy F. Foley: Bond strength comparison of moisture insensitive primers: Am J Orthod2002; 122:267-73.

19. Rangaswamy Rajagopal, Sridevi Padmanabhan, Janakirama Gnanamani : A Comparison of Shear Bond Strength and Debonding Characteristics of Conventional, Moisture-Insensitive, and Self-etching Primers In Vitro: AO 2004;74:264–268.

20. Irene L. Zeppieri, Chun-Hsi Chung, and Francis K. Mante : Effect of saliva on shear bond strength of an orthodontic adhesive used with moistureinsensitive and self-etching primers, Am J Orthod2003;124:414-9.

21. Littlewood SJ, Mitchell L, Greenwood DC, Bubb NL, Wood DJ. Investigation of a hydrophilic primer for orthodontic bonding: an in vitro study. J Orthod 2000; 27:181-6.

22. Rix DW, Foley TF, Mamandras AH. A comparison of bond strength of three adhesives: composite resin, hybrid GIC, and a glass filled GIC. Am J Orthod2001; 119:36-42.

23. Bearn DR, Aird JC, McCabe JF. Ex vivo bond strength of adhesive precoated metallic and ceramic brackets. BJO. 1995; 22(3):233–236.

24. Bishara SE, Olsen M, Von Wald L. Comparisons of shear bond strength of precoated and uncoated brackets. Am J Orthod. 1997; 112(6):617–621.

25. Bishara SE, Ajlouni R, Laffoon J, Warren J: Effects of modifying the adhesive composition on the bond strength of orthodontic brackets. Angle Orthod. 2002;72(5):464–467

26. Vittorio Cacciafesta, Maria Francesca Sfondrini, Andrea Scribante,: Effects of blood contamination on the shear bond strengths of conventional and hydrophilic primers: Am J Orthod2004;126:207-12

|