Introduction

Contamination of dental impressions with saliva and blood from the oral cavity occurs readily in dental clinics. Direct interaction between dental clinics and dental laboratories makes contaminated dental impressions difficult items to deal with from the cross infection point of view. Previous reports indicated that contaminated impressions can cross-infect gypsum casts that were poured against them[1]. Until 1991, rinsing impressions under running water was the recommended practice[2]. Guidelines for infection control in dental health care suggested that all dental prostheses and prosthodontic items should be cleaned, disinfected, and rinsed before they are handled in the laboratory using an active hospital disinfectant[3],[4]. The role of a disinfectant should, ideally, be of a dual purpose, it must be an effective antimicrobial agent, yet cause no adverse response to the dimensional accuracy and surface features of the impression material and the resultant gypsum cast[5]. The entire dental staff is routinely exposed to numerous viral and bacterial pathogens that have the potential to cause serious illness and even death. At present much attention is being given to the prevention, transmission of acquired immuno deficiency syndrome and hepatitis – B in the dental clinics and laboratories. The AIDS virus is known as HIV (Human immunodeficiency virus), while HBV (the hepatitis – B virus) is the causative organism for hepatitis – B. Persons, who are carrier of HIV and HBV, clinically do not show any signs of these diseases but are equally capable of transmitting the infection, the number of undetected carriers is much more than the number of person showing clinical signs6. Moreover the viruses of AIDS and Hepatitis B do not become immediately non infectious when outside of the body and they remain infective for 7 days[7].

In addition to blood, transmission of hepatitis-B through infected saliva has been well documented. Although, primarily blood has been implicated in the transmission of AIDS, the virus (HIV) has been isolated from the saliva of infected individuals. Whilst the likelihood of such a mode of transmission may be contentious particularly with regard to saliva, as has been pointed out by "Centres for Disease Control[8]” dentistry rarely sees saliva without some blood mixed into it. Truly so, since there is hardly any dental procedure; probably except complete denture service, where in blood effusion is not encountered. The best way of handling AIDS, hepatitis-B or any other transmissible diseases is to take at least the routine precautions. The development of an effective infection control programme in the dental clinics is a necessity and requires a concerted effort by the practitioner and auxiliary staff. Among such precautions little thought has been given to the items that pass from the clinic to the laboratory. It is inevitable that items such as impressions, occlusal rims and prosthesis might be contaminated with microbial flora of the mouth.

Contamination of dental impressions with varying amounts of blood and saliva is a routine occurrence. Therefore, these impressions must be considered potent enough to transmit diseases including AIDS and hepatitis-B, to all dental personnel who routinely handle them. Furthermore, it has been shown that contaminated impressions can cross-infect the gypsum casts, obtained from such impressions. . It is therefore, imperative that the recommendation of the "Centre of Disease Control" and that of "British Dental Association" for disinfecting dental impression are followed for all patients.

It is important for the Dentist to know the possible changes, which may occur in the gypsum cast subsequent to the immersion of impression in disinfectant solutions) since the dental cast forms the foundation for the fabrication of various prosthesis and appliances. Any dimensional change in the cast would lead to inaccurate prosthesis fabrication. The present study was an attempt at estimating possible changes in some physical properties such as linear dimension, surface details reproduction, strength and hardness of gypsum casts obtained from impressions treated by various chemical disinfectants.

Hence, this in vitro study was carried to estimate possible variations in the linear dimensions, surface details, strength and hardness of gypsum casts produced after immersion in disinfectant solutions in comparison to their respective control.

Aims & Objectives

The purpose of this study was to estimate possible variations in the linear dimensions, surface details, strength and hardness of gypsum casts produced after immersion in disinfectant solutions in comparison to their respective control.

Materials And Method

Material and Equipments

The material and equipment used in the study were as follows:

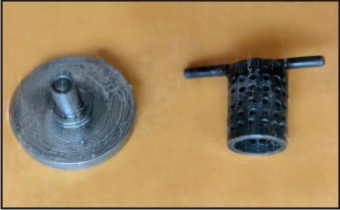

1. Master Die : For registering identical impressions a master die of steel was used. This die was self designed to have a circular base and centrally located cylindrical stump of 12mm height and 6mm diameter. They were divided as –

Master die with impression tray A

Master die with impression tray B

2. Circular Groove : A circular groove of 1mm width and 1mm depth was made on top of stump for studying surface details changes.

3. Impression Trays : Loosely fitting rigid steel caps with multiple perforations (to lock the impression material) were fabricated to be used as impression trays. Two trays were prepard one for each impression material :-

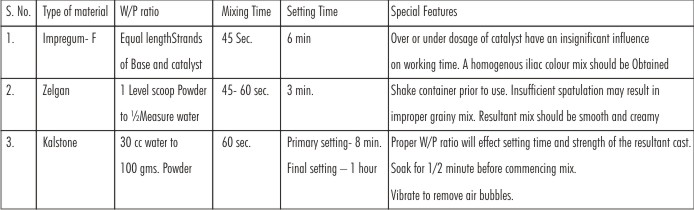

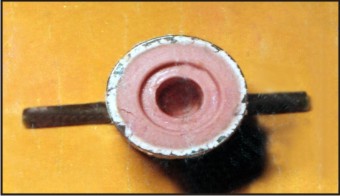

a. One for use with elastomeric impression material with uniform space of 2 mm. (Fig.1)

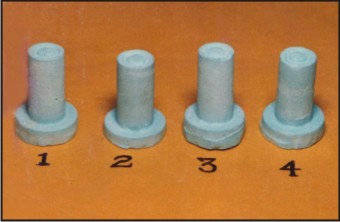

b. Second for use with hydrocolloid impression material with uniform space of 6 mm (Fig.2 )

4. Impression Materials :- two types of impression materials were selected for study purpose-

a) Elastomeric impression material (Impregum F)

b) Hydrocolloid Impression material (Zelgan)

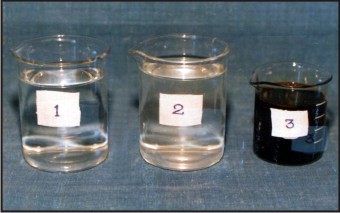

5. Disinfectant Solutions:- they were numbered as - (Fig.3)

1. 2% Glutaraldehyde

2. 1% Sodium hypochlorite

3. 5% Povidine Iodine

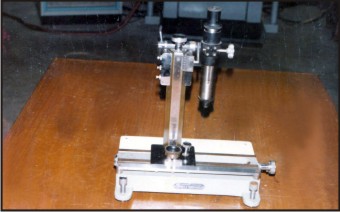

6. Optical Measuring Microscope (Fig.4)

7. Instron Model testing Machine :- To test the casts for compressive strength.(Fig.5)

8. Moh’s Hardness tester:- To test the scratch hardness of Gypsum casts

9. Miscellaneous Instruments

a) Two Separate rubber bowl

b) B.P. Knife

c) Lacron carver

| Fig.1 Master Die With Impression Tray A

|

| Fig.2 Master Die With Impression Tray B

|

| Fig.3 Disinfectants Solutions Used In The Study (1. 2% Glutaraldehyde Solution, 2. 1% Sodium Hypochlorite Solution, 3. 5% Povidine Iodine Solution)

|

| Fig.4 Optical Measuring Microscope

|

| Fig.5 Instron Model Testing Machine

|

Method

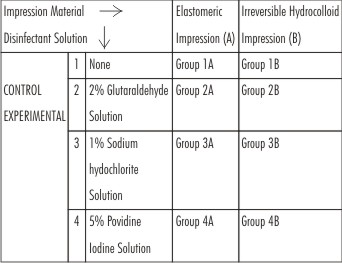

To evaluate the possible variations in the linear dimensions, surface details, strength and hardness of cast prepared from different impressions, impressions were divided into control and experimental groups.

The impression of control groups were poured without immersing them in any of the disinfectant solutions while that experimental groups were poured after immersing them in one of the disinfectant solutions. The casts of both groups were marked according to Table 1.

| Table 1: Table Showing Division Of Control And Experimental Group

|

Three impression and their correspond casts for each control and experimental groups were made.

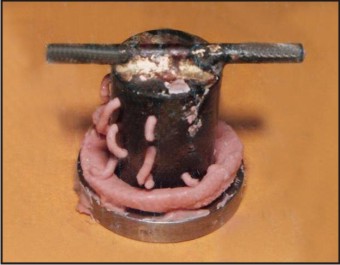

The elastomeric impression material used in this study was of single mix system. Equal lengths of base and catalysts were extruded on the mixing pad and were mixed thoroughly until a homogenous mix was obtained. The mixed impression material was first applied on the stump of the die and soon after was loaded in the impression tray no. A. Prior to loading of impression material the inside of the impression tray was painted with the tray adhesive. The loaded tray was then properly seated on the die so as to ensure complete contact with the base of the die, (Fig.6) the whole procedure of impression making was accomplished according to manufacturer’s instructions as shown in Table-II.

| Table 2: Table Showing Manufacturers Instruction For Materials Used In The Study

|

| Fig.6 Loaded Tray With Elastomeric Impression Material On Master Die

|

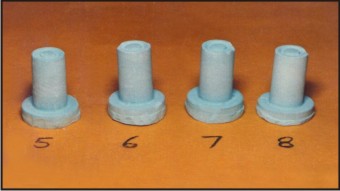

The impression of control groups was rinsed thoroughly with tap water and immediately the cast was poured in dental stone. (Fig. 7).

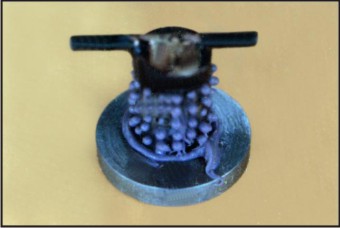

| Fig.7 Gypsum Casts Obtained From Elastomeric Impressions Of Control And Experimental Group (1. Casts Of Control Group 1 A, 2. Casts Of Experimental Group 2a , 3. Casts Of Experimental Group 3a , 4. Casts Of Control Group 4 A )

|

In the experimental groups three impressions (one for each disinfectant solution) were made. First impression was disinfected by 2% Glutaraldehyde while second and third impressions were disinfected by 1% Sodium hypochlorite and 5% Povidine Iodine respectively. On removal from die each impression was completely immersed in its respective disinfectant solutions for 15 minutes. (Fig. 8).

| Fig.8 Irreversible Hydrocolloid Impression In 2% Glutaraldehyde Solution

|

The powder of irreversible hydrolloid impression material was well shaken to loosen powder particles. One level scoop of powder was mixed with ½ measure of water in clean and dry rubber bowl with the help of stainless spatula, to achieve smooth, homogenous and creamy mix. The mixed material was then applied on the stump all around and soon the tray was loaded and properly seated on the die so as to ensure complete contact with the base of the die. (Fig.9 & Fig.10) showing irreversible hydrocolloid impression of master die. The casts of irreversible hydrocolloid impressions for control and experimental groups were poured in dental stone under similar conditions and using same procedures as were made for elastomeric impressions.(Fig. 11).

| Fig.9 Loaded Tray With Irreversible Hydrocolloid Impression Material On Master Die

|

| Fig.10 Irreversible Hydrocolloid Impression Of Master Die

|

| Fig.11 Gypsum Casts Obtained From Irreversible Hydrocolloid Impressions Of Control And Experimental Group (5. Casts Of Control Group 1 B , 6. Casts Of Experimental Group 2b, 7. Casts Of Experimental Group 3b, 8. Casts Of Control Group 4b)

|

The set casts were measured in the laboratory of advanced center of material Sciences, IIT Kanpur for

a) Linear dimensional change – Studied by measuring casts from top to the base of stump using optical measuring microscope.

b) Surface detail reproduction – Studied by measuring width and depth of grooves at three different point and then by taking average value of that measurement.

c) Compressive strength and hardness of the cast – Studied by measuring 24 hours compressive strength of cast using instron 1190.

Compressive strength (in Mpa) = Compressive load in Newtons

------------------------------------

Area in mm

The hardness of gypsum casts of control and various experimental groups were tested on Moh’s hardness scale.

Results And Observations

Sample casts were prepared for estimation of variations in linear dimension, surface details, strength and hardness. They were divided into 4 groups.

Group – 1: Cast obtained from untreated impressions (both A and B).

Group – 2: Cast poured from impression (both A and B) treated with 2% glutareldehyde solution.

Group – 3:Cast poured from impressions (both A and B) treated with 1% sodium hypochlorite solution.

Group – 4:Cast poured from impressions (A and B) treated with 5% povidine iodine solution.

The results obtained are expressed in form of tables as given below:

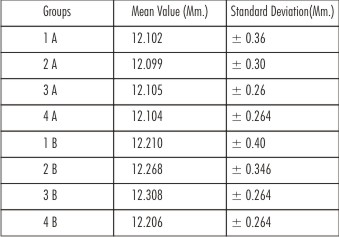

Table - III showing changes in linear dimensions of casts of different groups (linear dimension of steel master die is 12.052 mm )

| Table 3: Table Showing Changes In Linear Dimension Of Casts Of Different Groups

|

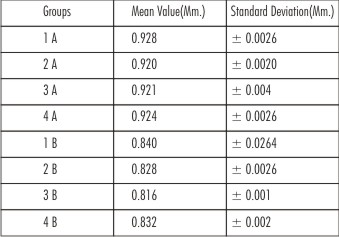

Table - IV showing changes in width of groove of casts of different groups (width of groove on master die was 1.001mm )

| Table 4: Table Showing Changes In Width Of Groove Of Casts Of Different Groups

|

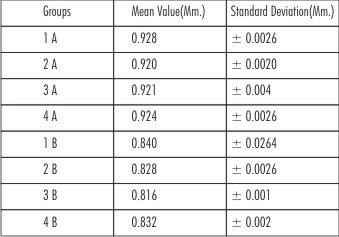

Table - V showing changes in depth of groove of casts of different groups (depth of groove on master die was 1.0 mm )

| Table 5: Table Showing Changes In Depth Of Groove Of Casts Of Different Groups

|

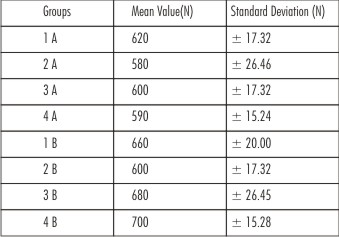

Table - VI showing changes in crushing loads of casts of different groups.

| Table 6: Table Showing Changes In Crushing Load Of Casts Of Different Groups

|

Discussion

Minimizing the risk of disease transmission in the dental workplace has today become a high priority for the dental profession. Contaminated materials are routinely sent to dental laboratories thus creating an occupational hazard. Disinfection of impression by disinfectant immersion has been tried out successfully for quite some time. At this juncture it seems pertinent to evaluate dimensional integrity of such impression subsequent to immersion in disinfectant solutions, in order to predict the accuracy of dental casts that will be obtained from them. This, in essence is an estimation of the behavior of the impression material in the moist environment and the reactivity of impression material with the disinfectant per se.

Impression materials have been known to suffer physically in the presence of moisture[9] as well as being susceptible to the possible chemical actions of different disinfectant solutions. The present study was an attempt to enunciate the physicochemical effect of disinfectant solutions on certain selected impression materials, barring two impression materials i.e. polyether type elastomers and irreversible hydrocolloids, the other impression materials known to be not affected significantly in a humid environment in previous studies[10],[11]. Opinions regarding these two impression materials differed so widely that it was decided to investigate further into their behavior so as to arrive at a coherent conclusion.

To assume near accurate repeatability of multiple impressions for multiple casts required in the study a single dimensionally stable master die was essential. It was made of steel and was machined to have a uniform diameter of 6 mm and length of 12 mm. A concentric groove of 1 mm width and 1 mm depth on its top was made to study the changes in surface detail reproduction. This stump was situated on a uniform base with a collar all around it. This collar was made to protect the impression from tearing during its removal from the die. The die had a polished surface to facilitate easy separation from impression and to produce smooth impression surface. The above said dimensions of steel die conformed to the ADA specification for gypsum for compressive strength test. As observed the relief to be provided in the impression tray was dependent on the body of the impression material which in effect was actually the flow of the material. Irreversible hydrocolloid which had poor flow would on setting possess greater body bulk than would the more easily flowing elastomeric impression material do. Keeping this in mind, tray relief provided for the elastomeric impression material was 2 mm and that for irreversible hydrocolloid was 6 mm. Multiple holes in impression trays were a measure to provide anchorage to impression material.

After complete setting of impression material, the loaded impression tray was removed from the master die with a snap jerk to eliminate chances of tearing due to the drag of material. 2% glutaraldehyde solution, 1% sodium hypochlorite solution and 5% povidine-iodine were selected as disinfectant solutions because they all are potent to kill the micro-organisms of AIDS and hepatitis B in a 10 minute exposure time, according to the studies on chemical disinfectants viz. that of Bond et al.[12], Howard et al.[13], Kabayashi et al.[14], Kabayashi and Tsuzuki and Prince et al.[15].

In the present study, impressions were immersed in the disinfectant solutions for 15 minutes, to increase the exposure time by five minutes. This was to ensure total elimination of micro-organisms from the impression surface.

The impressions of both experimental and control group were washed with running tap water and free water was blown out with compressed air to eliminate any source of error. Since gypsum acquires optimum strength in 60 minutes[9], the gypsum casts were allowed to set for 60 minutes. Premature removal or leaving the cast in the impression for too long could have resulted in rough and chalky cast.

For evaluation of the changes in linear dimensions, an optical measuring microscope was used. Each cast was measured three times by one investigator and the average of 3 readings was taken. The result of this study indicated that the linear dimensions of the casts were not much affected by the disinfectant immersion and changed insignificantly. These results for irreversible hydrocolloid impression materials were in concurrence with the studies earlier made by Herrera et al[16], Durr et al [17] who also did not find any significant linear dimensional changes, whereas Tullner et al[11] had reported that 1% sodium hypochlorite solution attacked and partially dissolved the surface of the irreversible hydrocolloid impression. They also suggested that there was significant difference between different brands of impression materials and that this should be considered in reflecting an appropriate disinfectant. In the present study, however, the Sodium hypochlorite solution did not attack the irreversible hydrocolloid impression material further supporting the suggestion of Tullner et al[11]. No significant change in linear dimensions of polyether type elastomeric impression material was observed in the present study which is in conformity with the findings of J.B. Tullner[11] and in contrast with the study of Storer[10].

The reproduction of surface details by the impression materials would essentially be dictated by its density and flow. High density materials would possess poor flow; hence a material which has both these properties would only be able to reproduce surface details most accurately. Results in control group showed a better reproduction of surface details with polyether type elastomeric impression material. This could be because of density and flow of this material which was much superior to irreversible hydrocolloid impression material. The reaction of the various disinfectants with impressions could either be physical i.e. sorption of liquid by impression material and its resultant "swelling up" or a chemical reaction between the two which could alter the impression surface. This possibility was evaluated by observing the dimensions of the groove reproduced on gypsum casts of experimental group with those of control group. The results pointed out a mean discrepancy in the range of 0.001 mm to 0.012 mm for various impression material/disinfectant combinations, which clearly indicated that surface details reproduction was not significantly altered by immersion in the different disinfectant solutions. Even when observed with the naked eye the surface of gypsum casts in different experimental groups did not display any surface roughness or irregularity in comparison to control group casts. Moreover, the treatment with 2% glutaraldehyde solution markedly enhanced the surface smoothness of the casts as reported in earlier studies. The compressive strength of the casts of experimental group did not change significantly either clinically or statis-tically (level of significance 0.05).

Docking[18], reported the absorption of certain additives that created additional nuclei for crystallization within the gypsum structure leading to denser structure and increased strength investigating further into the setting of gypsum. They found that incorporation of certain organic acids and their salts in gypsum led to increased setting time and decreased strength. These two contrasting observations could best be explained by the fact that additive used in the earlier study did not induce any chemical reaction whereas the additives in the second study chemically reacted to gypsum to form such products which not only inhibited setting but also did not provide additional nuclei for crystallization and thus did not contribute to any increase in strength. When impression was treated with various disinfectant solutions, then the ions or molecules of the solution did go into the surface bulk of impression material, which ultimately affected the setting gypsum casts which were in close contact with impression surface. When the solution molecules went into the structure of gypsum, the gypsum underwent the changes to accomodate solution molecules hence we got a modified material. The molecular arrangement of this material was different from its parent bulk which resulted into changed compressive strength. If this new molecular arrangement increased the affinity of molecules for each other, it resulted in increased compressive strength. On the other hand if the new molecular arrangement decreased the affection of molecules for each other, it resulted into the decreased comprehensive strength. Any material changes its shape on application of outside force or energy such as heat, tension, compression, shear, abrasion, crack etc. Out of all these the forces normally met during the various dental procedures on gypsum cast are compression, shear or tension and abrasion.

All these forces can be limited to the hardness of material because hardness is usually defined as a resistance of a material to deformation. Hardness of the material is dependent on its various other properties like strength, proportional limit, ductility and malleability and resistance to abrasion. Tabors[19] had suggested a similarity in shape of flow curve (load/deformation curve) and the curve obtained when hardness was measured. Thus compressive strength and hardness are directly proportional to each other.

The most commonly acceptable concept of hardness and the basis of majority of the tests to estimate it, are based on the resistance to indentation of a particular material.

The only scale which could be applied to our casts was scratch hardness test. Scratch hardness is of primary interest to the mineralogist. With the measure of hardness, various materials and minerals are rated on the ability to scratch one another. This consists of 10 standard materials arranged in the order of their ability to be scratched. The softest material in the scale is talc (Scratch hardness No. 1), while diamond has a hardness of 10 (maximum). All the casts whether obtained from treated impressions or from untreated impressions could not be scratched by talc, but could be scratched by finger nail; hence all of them fall between scratch hardness No. 1 and 2 on the Moh's scale. But when the casts of control and experimental groups were scratched against each other, equal abrasion was found on both of the casts. Hence, no significant change in hardness was there. The same results could be confirmed by the variation in compression test, made on sample cast, as compressive strength is directly proportional to the hardness according to Tabor[19].

Thus all these changes in the resultant casts which were obtained by impressions after immersing them in different dinsinfectant solutions, were insignificant statistically and clinically but these changes of insignificant magnitude confirmed the effectivity of our disinfectant procedure. As described earlier, these changes in bulk properties were due to the changes in molecular arrangements. It means that disinfectant solutions could be going to molecular level and hence really effective in Killing of possible microorganisms present the impressions.

Conclusions

The following conclusions were drawn

a) Change in the linear dimension of gypsum cast of different experimental groups was insignificant compared to that of the control group.

b) Immersion of the impression in the various disinfectant solution did not significantly affect the reproduction of surface details on gypsum casts.

c) Polyether impression material registered better surface details than irreversible hydrocolloid impression material.

d) Variations in values of compressive strength of gypsum casts of various experimental groups was not significant when compared with the values of the control group.

e) The hardness (scretch hardness) of gypsum cast on Moh’s scale did not show any change, after disinfectant treatment of the impressions.

f) The changes in the bulk properties of the impression material were due to the changes in their molecular arrangement. Thus it is evident by these insignificant changes in above mentioned properties, that penetration of the disinfectants used, was upto the molecular level and hence, they could be really effective in the destruction of micro-organism, if any, present in the impression.

g) It was seen that no significant changes occurred in the physical properties analysed in this study, after the impressions had been disinfected with the three disinfectants used. Hence, it was concluded that routine disinfection of dental impressions should be done to ensure elimination of certain afflictions viz. AIDS and hepatitis B without endangering the dimensional accuracy, surface details, compressive strength and hardness of the gypsum casts obtained from such impressions.

References

1. Leung RL, Schonfeld SE. Gypsum casts as a potential source of microbial cross-contamination. J Prosthet Dent 1983; 49:210-211.

2. Fabiani L, Mosca G, Giuliani AR. Hygiene in dental practices. Eur J Paediatr Dent 2006;7:93-97.

3. Infection control recommendations for the dental office and the dental laboratory. ADA Council on Scientific Affairs and ADA Council on Dental Practice. J Am Dent Assoc 1996;127:672-680.

4. Kohn WG, Collins AS, Cleveland JL, Harte JA, Eklund KJ, Malvitz DM. Guidelines for infection control in dental health-care settings--2003. MMWR Recomm Rep 2003;52:1-61.

5. Taylor RL, Wright PS, Maryan C. Disinfection procedures: their effect on the dimensional accuracy and surface quality of irreversible hydrocolloid impression materials and gypsum casts. Dent Mater 2002; 18:103-110.

6. Barre, S.F. et al. (1985) Transmission of AIDS, Lancet, 28: 721 – 722.

7. Bond, W.W. et al. (1981) Survival of hepatitis B virus after drying and storage for one week, Lancet, 1: 550 – 557.

8. Centers for disease control (1985). MMWR, 34: 533-534.

9. Phillips, R.W. (1982). Skinner’s Science of dental materials, 126-155, Eighth edition, Philadelphia: Saunders.

10. Storer, R. and McCabe, J.F. (1981). An investigation of methods available for sterilizing impressions. British Dental Journal, 151: 217-219.

11. Tullner, J.B., Commette, J.A. and Moon, P.C. (1988) Linear dimensional changes in dental impressions after immersion in disinfectant solutions, Jour. of Prosth. Dent. 60: 725-728.

12. Bond, W.W. et al. (1983) Inactivation of hepatitis B virus by intermediate to high level disinfectant chemicals, Journal of Clinical Microbiology, 18: 535 – 538.

13. Howard, C.K. & Dixon, J. et al. (1983) Chemical inactivation of hepatitis B virus: The effect of disinfectants on virus associated DNA polymerase activities. Morphology and Infectivities, Jour. of Virological Methods, 7: 135 – 148.

14. Kobayashi, H. et al. (1984) Susceptibility of hepatitis B virus to disinfectants or heat, Jour. of Clinical Microbiology 20: 214 – 216.

15. Prince, A.M. et al. (1984). Inactivation of hepatitis B and non A non B hepatitis viruses by exposure to Tween 80 and Ether. Vox Sanguinis, 46: 36-43.

16. Herrera, S.P. & Merchant , P.A : Dimensional stability of dental impressions after disinfection ; 1986:113:419-422.

17. Durr, D.P. and Novak, E.V. (1987). Dimensional Stability of alginate impressions immersed in disinfecting solutions, Journal of Dentistry for Children, 54: 45 – 48.

18. Docking, A.R. (1960). Australian Dental Journal, 5: 306.

19. Tabor, D. (1951) The hardness of metals, Journal of Institution of Metallurgy, 79: 1.

|