Introduction:

Loss of teeth is one of the major concern to patient both aesthetically as well as functionally, so their replacement by artificial substitutes such as dentures is vital for their functioning of their life. Denture base acts as an intermediate medium between teeth and the jaw which transfer’s all or part of the masticatory forces to the subadjacent tissues. One of the major limitation of such prosthesis is strength and fracture morphology of denture base materials used for such prosthesis[1]. Dootz et al[2] has shown that material aging can dramatically affect the physical and mechanical properties of material, prediction of the service life of acrylic resin material is difficult since many extraoral and intraoral factors affect durability. Impact failure outside the mouth and flexure fatigue failure in the mouth are the two most important causes of fracture of denture base[3].

The study was undertaken in order to enable a general dentist to know the properties like impact strength, fracture morphology have great impact on prediction of service life of denture base material and incorporate this result in choosing a resin for denture base fabrication.

Also the study of this type will lead to awareness for the need of establishing a suitable program for testing of denture base materials and the measures adopted to increase the impact strength for same.

Materials & Methods:

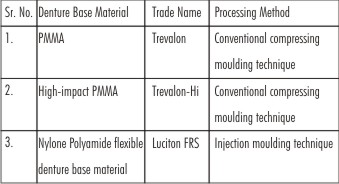

The three denture base materials used in the study are Trevalon(Poly Methyl Meth Acrylate), Trevalon-Hi(High-impact PMMA), Luciton FRS(Nylone Polyamide flexible denture base material). All these materials were manufactured by Dentsply (Table - 1).

| Table 1: Showing 3 Denture Base Materials Along With Trade Name And Processing Methods.

|

Ten rectangular specimens measuring 65mm in length, 10mm in height, and 2.5mm in thickness were prepared for each acrylic resin[4],[5] according to the manufacture’s recommendations in following manner (Figure 1).

| Figure 1: Showing Rectangular Strips Of Three Respective Groups(A,B,C)

|

First, the wax was cut with dimension of 65mm in length, 10mm in height, 2.5mm in thickness; dimensions were checked with help of digital vernier caliper. Thirty wax patterns were made and invested with dental stone in metal flask for dewaxing. Denture base acrylic resins of Trevalon and Trevalon-Hi were mixed according to the manufacture’s instructions and packed into dewaxed patterns, after dewaxing of wax patterns, when the materials reached the dough stage. These specimens were polymerized with conventional compressing moulding technique. Specimens, after polymerization, were checked again with vernier caliper to verify the dimensions.

Denture base acrylic resin of Luciton FRS was cured with injection molding technique. For this group injection moulding technique Success System of Dentsply was used.

Testing was done on Izod impact testing machine (CEAST S.p.a., Turin, Italy) (Figure 2) with a pendulum of load 7.5J in air at 31±3ºC. Before testing, pendulum was released to freely swing in the air to record the air resistance (AR) encountered by free-swinging pendulum[4],[5]. Air resistance of 0.7 Joules was recorded. The readings were taken on scale where pointer was stabilized after swing. The specimen was clamped in vertical position precisely and fractured by the pendulum. Pendulum was released and reading indicating energy absorbed (EA) to break the specimens on scale was recorded. All the specimens were tested in the same manner. Impact strength of specimen was calculated by using following formula -

| Figure 2: Izod Impact Testing Machine

|

Impact strength = Corrected Readings/ W

Where, Corrected readings = (EA - AR) in Joules

W = Test specimen width in meter

Impact strength = J/m

For fracture morphology test under SEM, one fragment of the each sample was taken and cut 2mm from the fractured surface with the help of micromotor and carbonadum disk. Then it was coated with gold, so as to increase the density of electrons striking the fractured denture base. All fragments from both polymerization cycles were subsequently submitted to SEM (LEO, 430, Germany) to verify micro structural behavior and fracture morphology (Figure 3).

| Figure 3: Scanning Electron Microscope

|

Statistical Analysis:

The statistical tests used in this study were:

(a) Means of strengths were compared using ANOVA.

(b) Student “t” test was used for comparision between the groups.

Confidence level was kept at 95%. ‘p’ value >0.05 denoted a statistically significant difference.

Results

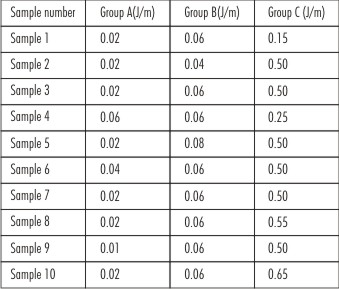

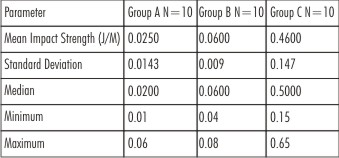

10 samples were taken for each of the groups A, B, C. Table 2 shows impact strength of each sample (n=10) in 3 respective study groups. Table 3 shows mean impact strength, standard deviation, minimum, maximum and median value of impact strength in all 3 groups.

| Table 2: Showing Impact Strength Of Samples In Three Groups:

|

| Table 3: Comparative Impact Strength Values Of The Three Groups

|

The mean impact strength of Group A was 0.0250±0.0143 J/m followed by 0.060±0.009 in Group B and 0.460±0.147 J/m in Group C. Minimum impact strength was recorded as 0.01 J/m for a specimen of Group A while maximum impact strength was recorded as 0.65 J/m in Group C. The median impact strength for each group was 0.020, 0.060 and 0.500 J/m respectively in each group. The differences among groups were broad as was evident by the range of impact strength values in the two groups. While in Group A the minimum to maximum range was 0.01 to 0.06 J/m, in Group B it was 0.04 to 0.08 J/m, showing a limited scope for overlapping impact strength values. In Group C, these were markedly differentiated with minimum value starting from 0.15J/m and maximum reaching upto 0.65J/m. Table 4 shows analysis of Variance in the three groups under study.

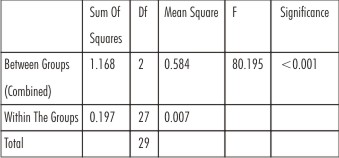

| Table 4: Analysis Of Variance In The Three Groups Under Study

|

On comparing the variance among the groups, the F-ratio was calculated as 80.195 which was statistically highly significant (p<0.001) at degree of freedom 29. The analysis of variance thus revealed a statistically significant difference among the three groups.

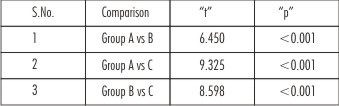

Table 5 shows comparison between the groups. The mean impact strength value of Group B was significantly higher as compared to Group A (p<0.001), that of Group C as compared to Group A (p<0.001) and that of Group B as compared to Group C (p<0.001).On the basis of above results and statistical analysis the impact strength of the three groups could be depicted as:

Group C > Group B > Group A

| Table 5: Intergroup Comparison

|

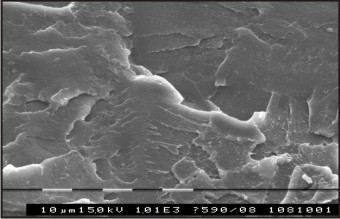

For fracture morphology, SEMmicroscopy showed that group - A, which is most brittle as compared to other groups, exhibited well - defined, flat, compact and organized surface fracture, it showed some grooves, but depth of grooves was least amongst the three groups (Figure 4)

| Figure 4: Sem Fracture Morphology Of Group A

|

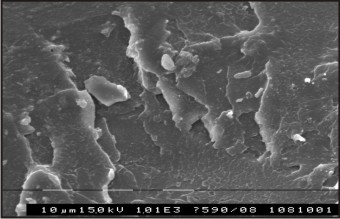

Group-B, which lesser brittle material than group-A, exhibited disorganized and jagged and irregular surfaces, when compared to the group-A with, high number of grooves are present. Crazing was present in group-B. The grooves were also present and the depth of grooves were higher than group-A (Figure 5).

| Figure 5: Sem Fracture Morphology Of Group B

|

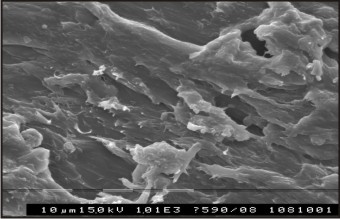

Group-C, which showed highest impact strength, exhibited completely disorganized and the most irregular and jagged surface amongst the three groups. It showed highest number of grooves, which are deepest among the three groups. The highest crazing was present in group-C (Figure 6).

| Figure 6: Sem Fracture Morphology Of Group C

|

Discussion

Mechanical properties of denture base resins are crucial for the clinical success of prosthesis. Impact strength is also a desirable property because it is a measure of the energy required to initiate and propagate a crack through the material. Thus, it can reflect the contact force needed to cause fracture in a denture under situations such as accidental dropping[6]. A study by Johnston et al[7] showed that 68% of acrylic resin dentures break within a few years after fabrication primarily due to impact failure. The occurrence of fracture, observed in maxillary and mandibular prostheses[8] results in additional costs, as well as discomfort to patients[9] as they must be without the dentures during the laboratory procedures required to repair or replace the broken denture.

In 2006, Fernanda Faot et al[5] evaluated the impact strength and fracture morphology of different denture base acrylic resins. They fabricated twenty specimens measuring 65 × 10 × 2.5 mm from each of 4 acrylic resins processed according to the manufacturers’ recommendations: Lucitone 550 (control; 9 hours at 74°C); Onda Cryl (3 minutes at 360 W + 4 minutes pause + 3 minutes at 810 W); Acron MC (3 minutes at 500 W); and Vipi Wave (20 minutes at 180 W + 5 minutes at 540 W). The impact strength was evaluated in an impact testing machine using the Charpy method with a load (impact action) of 3.95 J. They investigated that significant differences (P<.001) were found in the impact strength for Vipi Wave and Acron MC acrylic resins, which demonstrated the lowest values (0.19 ± 0.04 and 0.21 ± 0.02, respectively). Most fractures were classified as brittle (Lucitone 55%; Onda Cryl 75%; Acron MC 90%; Vipi Wave 65%). They used SEM for fracture morphology test. The SEM observations revealed that brittle fractures showed defined and organized crystallographic planes, whereas the intermediate fractures had a disorganized appearance. Analysis of fracture surfaced by SEM showed that the microstructural behavior of brittle and intermediate fractures in Lucitone and Onda Cryl resins was similar. Acron MC Resin showed an intermediate model of crystallographic plane configuration for both fracture types. Vipi Wave resin showed poorly defined crystallographic plane with a certain degree of disorganization, and these fracture surfaces were different from those of other resins.

The results were same as in present study, but the values of impact strength were different. The values of impact strength of this study were lower. In this study, the notch was made in each sample, so that the minimal impact strength could be measured of each type of material.

In this study, the fracture morphology of denture base material which had lowest impact strength that was group-A exhibited well defined, flat, compact and organized fractured surface and the fracture morphology of denture base material which had impact strength more than group-A that was group-B exhibited disorganized and jagged and irregular surface when compared with group-A. Group-C that showed highest impact strength exhibited completely disorganized, more irregular and jagged surface than group-A and group-B. Similar fracture morphology was seen by Fernanda Faot et al, the denture base resins which had more impact strength values exhibited more number of intermediate fractures and those denture base resins which had low impact strength values, exhibited more number of brittle fractures.

Similar results was reported by Gianluca Zappini et al[10] in 2003. They used seven heat-polymerized denture base resins for the study: 5 high impact (GC Luxon, Injectall IPF HI-I, Ivocap Plus, Lucitone 199, and Trevalon HI) and 2 conventional (Major Base 2 and Probase Hot). Three series of 12 specimens were used for the Charpy impact test. The dimension of specimens is 80 × 10 × 4 mm, and notch depth: 2 mm and 2 Izod impact tests. The dimension of specimens is 80 × 10 × 4 mm, and notch depth: 1.2 mm for the first series, 3.4 mm for the second series. The results showed that GC Luxon and Lucitone 199 possessed the highest Charpy impact strength, while in both Izod impact measurements Trevalon HI showed the highest values. The final results were same as in present study, the denture base materials of hi- impact had more impact strength than conventional denture base materials. The values were higher than the values of the present study, because of dimension of the samples. Gianluca Zappini et al used two series of samples, the dimension of first series was is 80 × 10 × 4 mm, and of second series was 80 × 10 × 4 mm. But the dimension of each sample in the present study was 65x10x2.5 mm. The samples were notched, but notch was smaller than Gianluca Zappini et al study. In this study, notch was cut 2.5mm, which was 20% of the total width of the sample. But the notch of their study was 2mm for first series of samples and for the second series was 1.2mm and 3.4mm varies from 20% to 30%.

Some authors[11],[12],[13],[14],[15] reported that impact strength can be increased by adding carbon fibers, glass flakes, glass fibers or polyethylene fibers, but the fracture morphology of reinforced material has not been investigated yet. Further study can be taken up to evaluate the fracture morphology of such reinforced denture base resins.

Conclusions:

Within limitations of this in vitro study, following conclusions were drawn:

1. The mean impact strength of Luciton FRS(Group C) was significantly higher than both Trevalon-Hi(Group B) as well as trevalon (Group A).

2. Trevalon-Hi showed significantly higher mean impact strength as compared to Trevalon.

3. SEM microscopy showed that Trevalon is most brittle and exhibited well defined, flat, compact and organised surface fracture.

4. Trevalon-Hi is less brittle than Trevalon, exhibited disorganised and jagged, irregular surfaces.

5. Luciton FRS exhibited completely disorganized and the most irregular and jagged surface amongst the three groups.

References:

1. Darbar UR, Hugget R, Harrison A. Denture fracture a survey. Bri Dent J 1994;7:342-7.

2. Dootz ER, Koran A, Craig RG. Physical property comparison of 11 soft lining materials as a function of accelerated aging. J Prosthet Dent 1993;69:114-9.

3. Kelly E. Fatigue failure in denture base polymers. J Prosthet Dent 1969;21:257-66.

4. Annual Book Of ASTM Standards Section 8 plastic Volume 08.01 Plastic(1): D256 – D2343: Standard test for Determining the Pendulum Impact Resistance of Notched Specimens of Plastic; pages 1- 18.

5. Fernanda Faot, Marcelo Almeida Costa, Altair A. Del Bel Cury, Renata C.M. Rodrigues Garcia : Impact strength and fracture morphology of denture acrylic resins. J Prosthet Dent.2006 Nov; 96(5), 367-373.

6. Jagger DC and Harrison A. The effect of continuous poly(methyl methacrylate) fibres on some properties of acrylic resin denture base material. Eur J Prosthodont Restor Dent 2000; 8: 135–138.

7. Johnston EP, Nicholls JI, Smith DE. Flexure fatigue of 10 commonly used denture base resins. J Prosthet Dent 1981;46:478- 83.

8. Prombonas AE and Vlissidis DS. Comparison of the midline stress field in maxillary and mandibular complete dentures: a pilot study. J Prosthet Dent 2006; 95: 63–70.

9. Vallittu PK, Vojtkova H and Lassila VP. Impact strength of denture polymethyl methacrylate reinforced with continuous glass fibers or metal wire. Acta Odontol Scand 1995; 53: 392–396.

10. Gianluca Zappini, Axel Kammanna, Wolfgang Wachtera : Comparison of fracture tests of denture base materials. J Prosthet Dent.2003 Dec; 90 (6), 578-585.

11. A.J.Goldbergand C. J. Burstone.: The use of continuous fiber reinforcement in dentistry. Journal of Oral Dental materials. 1992 May; 8(3): 197-202.

12. J.DeBoer, S.G.Vermilyea, and R.E.Brady.:The effect of carbon fiber orientation on the fatigue resistance and bending properties of two denture resins. J Prosthet Dent. 1984 Jan; 51(1): 392-399.

13. Paul Franklin, David J. Wood, and Nigel L. Bubb. : Reinforcement of poly (methyl methacrylate) denture base with glass flake. Journal of Dental materials. 2005 April 21(4): 365-370.

14. Vallittu PK, Lassila VP, Lappalainen R.: Acrylic resin-fiber composite—Part I: The effect of fiber concentration on fracture resistance. J Prosthet Dent. 1994 Jun; 71(6):607-12.

15. Vallittu P.K., DT, BOdont : Acrylic resin-fiber composite—Part II: The effect of polymerization shrinkage of polymethyl methacrylate applied to fiber roving on transverse strength. J Prosthet Dent. Jun 1994; 71(6):613-7.

|