Introduction

DrWalterWright in 1937 introduced plastic denture base materials called Vernonite.by 1946 it was estimated that 95% of all dentures are made of this resin[1]. Despite its excellent properties there is need for improvement in its fracture resistance[2]. Fractures in denture results from two different types of forces, namely flexural fatigue and impact. The midline fracture in a denture is often a result of flexural fatigue.Methods to improve the inherent material properties of Polymethylmethacrylate resin have included reinforcing agents such as particulates, and fibers. The first approach is to increase the strength of denture base polymer by adding a cross-linking agent of polyfunctional monomer such as polyethylene glycol dimethacrylate[3]. Cross linking lowers strength and flexibility but increases solvent resistance, softening point, and hardness. Fatigue and impact strength are usually reduced[4]. The second approach is to devise a reinforcement of denture base polymer with fibers or rods such as metal fibers, carbon fibers, Aramid fibers and ultra high-molecular weight polyethylene fibers. The most commercially successful method of reinforcement is rubber toughening; inspite of thisthe material has compromised flexural properties. A rubber phase may be introduced into the acrylic matrix as either co-polymer, rubber particles or as core shell particles. Rodford described the dissolving of the butadiene-styrene co-polymer in methyl methacrylate monomer. Core shell particles are a development of the rubber toughening process, utilizing the arrangement of rubber and acrylic that imparts the greatest toughness upon the acrylic-namely a core of rubber phase material, surrounded by an acrylic shell.Smith (1957) reported on glass reinforcement of Polymethy lmethacrylate by simply mixing discrete fibers with the dough or by lamination with the glass cloth. The incorporation of glass fibers was limited to 20% due to the deleterious effects on the doughing properties above this percentage. Ideally, to strengthen polymer resins by including the glass fibers, there should be good adhesion between polymer matrix and the fibers. Silanization of the glass fibers will improve the adhesion between the fibers and the resin. Research into the use of glass fibers for the reinforcement of PMMA continues till date.The objective of the study was: -to compare the flexural strength of the conventional polymethylmethacrylate resin and high impact resin and glass fiber reinforced acrylic resin.

Materials and Methods

This was an invitro study which was performed to compare the flexural strengths of a commercially available heat polymerized acrylic denture base material (Group–A) control group, High impact resin (Group-B), Conventional resin reinforced with 2% glass fibers by weight (Group-C), and Conventional resin reinforced with 5% glass fibers by weight (Group-D),Group – B, C, D are the test groups.

A stainless steel die of dimensions 65 mm X 10 mm X 3 mm was fabricated to make one hundred and twenty acrylic specimens according to standard compression moulding technique and following short curing cycle. The four experimental groups consists of 30 samples of (Group–A) as control group, 30 samples each of (Group-B), (Group-C), and (Group-D). (Fig 1)

| Fig 1 : Specimens Retrieved

|

Group-B specimens were prepared in the above mentioned manner. The Group-C and Group-D which consists of conventional acrylic resins specimens of same dimensions reinforced with 2% and 5% by weight glass fibers. The glass fibers were cut to 5mm length. The cut fibers were subjected to salinization, thesilane coupling compound was wipe applied on the surface of the glass fiber and were allowed to dry in the air for 20 minutes. Later on they were soaked in the monomer for about 10 minutes to allow better bonding. The fibers were removed from the monomer, and the excess liquid was allowed to dry. The fibers and the preweighed resin were mixed thoroughly to disperse the fibers. After reaching its dough stage, the material was kneaded and packed into the prepared molds. The specimens were polymerized and recovered in the same manner as Group-A and Group-B. All the specimens were stored at room temperature in water for one week before testing.

Results

All the samples were tested for flexural strength using a 3 – point bending test with a universal testing machine (INSTRON – Model No 1011) at a crosshead speed of

2mm/min as shown in (Fig 2). A load was applied using a centrally located rod until a fracture occurred (Fig-3). The results were analyzed with a one-way analysis of variance (ANOVA) (Table no 1)

| Fig 2 : Testing for the Flexural Strength (Final Fracture)

|

| Fig 3 : Fractured Specimens

|

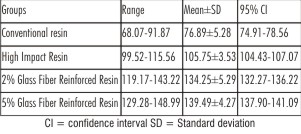

| Table 1 : Comparison of Mean pattern of Flexural strength in Mega Pascal units in four groups

|

The Flexural strength in Mpa for Group B was 105.75 3.53, and it wasGroup Cin was134.25 5.29 significantly (p < 0.001**; Tukey) raised over and Group D139.49 4.27 also significantly rose (p<0.001**; Tukey) when compared to the mean Flexural strength in Group B .The Flexural strength in Group C was 134.25 5.29 Mpa and inGroup D was 139.49 4.27 Mpa.

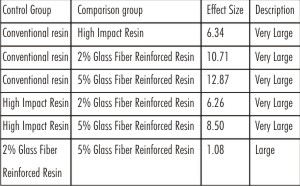

| Table 2 : Comparison of Effect sizes between the groups

|

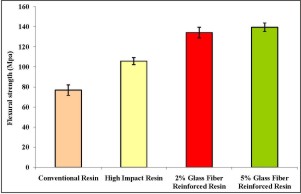

| Graph 1 : Comparison of average Flexural strength in Mega Pascal units in four types of materials

|

Discussion

Methods to improve the inherent material properties of Polymethylmethacrylate resin have included reinforcing agents such as particulates, and fibers. The first approach is to increase the strength of denture base polymer by adding a cross-linking agent of polyfunctional monomer such as polyethylene glycol dimethacry late (highimpactresin - Group - B). The second approach is to devise a reinforcement of denture base polymer with glass fiber (Group - C , Group - D). Silane coupling agents have been used successfully to improve adhesion between polymer and glass fibers. The function of the Silane coupling agent is based on two types of chemical bonds. One of those bonds is a Siloxane bridge formed by the condensation reaction of Silanol groups and the silica surface of glass fiber. Simultaneously with the condensation reaction, the Silanol molecule form hydrogen bonds.

Glassfiber reinforced denture base resin has many factors such as matrix resins, silane-coupling agents and glass fiber which affect water absorption.Glass fiber reinforcement increases dimensional change, which can compensate for polymerization shrinkage to certain degree.

The present study was to compare the flexural strength of conventional heat cure resin, high impact resin and Glass fiber reinforced resin using a three point bending testing machine.

For comparison of the flexural strength, 30 specimens from control group and 90 specimens i.e. 30 specimens from each test group has been tested. The peak load at which the Group-A specimens fractures ranged from 9.8kgf - 12.72kgf, and the flexural strength ranged from 70 Mpa - 90 Mpa. Group-B specimens’ fracture ranged from 14.01kgf - 16 kgf, and the flexural strength ranged from 100Mpa - 120 Mpa. Group - C specimens fracture ranged from 16.5 kgf - 19.5 kgf and the flexural strength ranged from 120 Mpa. - 138 Mpa. Group - D specimens fracture ranged from 18 kgf - 21 kgf and the flexural strength ranged from 135 Mpa. - 145 Mpa. Thus, higher the force required to fracture the specimens, greater is the flexural strength.

Inter group comparison among the three groups shows 6.34% increase in flexural strength in Group-B, 10.71% increase in flexural strength in Group-C and 12.87% increase in flexural strength in Group-D in comparison to Group-A. Analysis of variance showed that the difference in load at fracture and corresponding transverse strength was statistically significant (p<0.001**, Tukey).

Results of study showed substantial improvement of flexural strength in Group-C and Group-D i.e., the glass fiber reinforced specimens. This may be explained based on the fact that the modulus of elasticity of glass fiber is very high; most of the stresses are received by the fiberswith out any deformation.

From this study, it has been observed that the pretreated glass fiber by silane coupling agent improves a chemical bond with the acrylic polymer and the flexural strength. This modified method of reinforcing heat cure acrylic resin can be used in reinforcing the complete denture and distal extension partial denture bases, which are more prone to fracture by, fatigue failure in certain areas. Since the study has been restricted to laboratory investigations, further observations in clinical application are required.

Conclusion

From the results obtained in this study, the following conclusions were drawn:

1. It has been observed that the pretreated glass fiber by silane coupling agent improves a chemical bond with the acrylic polymer.

2. Therehas been considerable improvement in the flexural strength from conventional heat cure resin to the high impact resin because of the particulate reinforcement i.e. with the butadiene styrene.

3. A significant amount of increase in flexural strength has been noticed, and gives an inference that fiber reinforcement enhances the flexural strength when compared to the particulate reinforcement.

4. Results of study showed substantial improvement of flexural strength in Group-C and Group- D i.e., the glass fiber reinforced specimens.

5. There is a considerable difference in flexural strength between 2% and 5% glass fiber reinforced specimens. So the flexural strength can be increased by increasing the percentage fibers added to it. This will facilitate the improvement in strength up to 20%, above which will not improve the strength but makes manipulation difficult.

References

1. Floyd A. Peyton. History of resins in Dentistry. DCNA 1975; 19: 211-21.

2. Jacob John, Shivaputrappa A. Gangadhar. Flexural strength of heat polymerized polymethylmethacrylate denture base resin, reinforced with glass, aramid or nylon fibers. J Prosthet Dent 2001; 86: 424-7.

3. Paul Franklin, David J. Wood, Nigel L. Bubb. Reinforcement of polymethyl methacrylate denture base with glass flake.Dental materials 2005; 21: 365-70.

4. Smith DC. Recent Developments and prospects in dental polymers. J Prosthet Dent 1962; 12 (6): 1066-77.

5. Kanie T, Fujji K, Arikawa H, Inoue K. Flexural properties and impact strength of denture base polymer reinforced with woven glass fibers. Dental Materials 2000; 16: 150-58.

6. EysteinRuyter I, Dr. Rer, Svend A. Svendsen. Flexural properties of denture base polymers. J Prosthet Dent 1980; 43 (1): 95-103.

7. Beyli MS, Dr. Med. Dent, Von Fraunhofer JA. An analysis of causes of fracture of acrylic resin dentures. J Prosthet Dent 1981; 46 (3): 238-41.

8. Rodford R. The development of high impact strength denture base materials.J Dent 1986; 14: 214-17.

9. Murkani A. Rubber modified bone cement. J Materials Science 1988; 23: 2029-36.

10. Rodford R. Further development and evaluation of high impact strength denture base materials.J Dent 1990; 18: 151-57.

11. Gary S. Solnit. The effect of methyl methacrylate reinforcement with silane-treated and untreated glass fibers. J Prosthet Dent 1991; 66 (3): 310-14.

12. Robinson JG, McCabe JF. Impact strength of acrylic resin denture base materials with surface defects.Dental Materials 1993; 9: 355-60.

13. Vallittu PK. Comparison of two different Silane compounds used for improving adhesion between fibers and acrylic denture base material.J Oral Rehab 1993; 20: 533-39.

14. Vallittu PK, Bodont DT. Acrylic-fiber composite - Part 1: The effect of fiber concentration on fracture resistance.J Prosthet Dent 1994; 71: 607-12.

15. Vallittu PK. Acrylic resin-fiber composite - Part II: The effect of polymerization shrinkage of polymethyl methacrylate applied to fiber roving on transverse strength. J Prosthet Dent 1994; 71 (6): 613-7.

|