Introduction

The restoration of grossly decayed primary and young permanent teeth has always remained a challenge for the dentist. This problem was overcome by Humphrey who introduced Stainless steel crown in 1950.They are considered superior to large multisurface amalgam restorations with respect to both life-span and replacement rate[1]. The 8-year survival rate of 89% for stainless steel crowns is similar to the values of 88% reported by Messler and Levering[12]. They have proved efficacious and are relatively easy to use. They have been used for restoring hypoplastic, endodontically treated, malformed teeth and fractured teeth to perform their normal function. The success of Stainless steel crown depends on the quality of the tooth preparation together with selection and adaptation of an appropriate crown and luting cement[18],[19],[9]. The luting cements play an important role in the retention of Stainless steel crowns[19],[9].

A wide range of luting cements have been used for cementing the stainless steel crowns in the past which includes Zinc Phosphate, Zinc Polycarboxylate and Glass Ionomer cement. In recent years newer classes of cements such as Resin Modified Glass Ionomer and Resins are formulated with adhesive properties. The addition of resin to the cement formulation has allowed light curing, a snap set and rapid strength development. In addition they have better physical and mechanical features than the conventional GICs[17].

The present study aims to compare the mean retentive strengths of luting cements like Zinc Phosphate cement (Harvard), Resin Modified Glass Ionomer cements (Rely X Luting) and Adhesive resin cement (Rely X ARC) used for the cementation of stainless steel crowns.

Material and Methods

This study was undertaken in the Department of Pedodontics and Preventive Dentistry, Sardar Patel Institute of Dental and Medical Sciences, Lucknow in collaboration with the Department of Plastic and Composite Technology, Research Designs and Standard Organization, Lucknow using following materials and methods:

Methodology

A total of 60 extracted intact primary molars were selected for the study (12 maxillary primary first molars, 12 maxillary primary second molars, 12 mandibular primary first molars, 24 mandibular primary second molars).

The selected teeth were without caries or restorations and with root resorption rate lower than 2/3 rd. All the teeth were hand scaled and cleaned to remove debris. After that all the teeth were mounted in self-cure acrylic resin exposing complete crown.

The occlusal surfaces of the teeth were reduced uniformly to a depth of 1.0-1.5 mm with a 69 L and 169L bur. The mesial and the distal undercuts were removed with a tapering fissure diamond bur. All the sharp line angles were rounded.

| Figure 1: Sample Collected

|

| Figure 2: Stainless Steel Crowns (3m)

|

| Figure 3: Armamentarium

|

| Figure 4: Incubator

|

| Figure 5: Instron Universal Testing Machine

|

| Figure 6: Specially Designed Apparatus

|

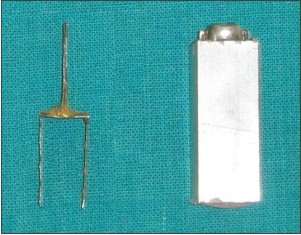

After that pre-trimmed and pre-contoured stainless steel crowns (3M ESPE Dental Co. St. Paul Mn) were adapted on the prepared teeth. The crowns had two opposing orthodontic attachments (Begg’s Brackets) spot welded to facilitate its easy removal.

60 teeth were equally assigned to three groups of 20 teeth each.

Group A – Cementation with Zinc phosphate cement

Group B– Cementation with Resin modified glass ionomer cement

Group C – Cementation with Adhesive resin cement

All the teeth were rinsed with water and then dried. After mixing each cement, they were loaded into the crown and then the crown was seated on the selected teeth with hand pressure. Excess cement was removed after 10 min the mixing began using hand instruments. After waiting for 10 min all the samples were transferred to artificial saliva in an Incubator at 37° C. Half of the specimens from each group were stored in artificial saliva for 1 day and another half for 7 days.

The Retentive strength was tested after I day and 7 days using an Instron Universal Testing Machine (Figure)in tensile mode. Each mounted tooth was clamped to the inferior vise grip of the UTM(Figure). A specially designed apparatus was attached to the superior grip of the universal testing machine to remove the cemented crowns.

Applied force was directed parallel to the long axis of the tooth during crown removal. The load was applied from zero and then gradually increased. The force required to initially dislodge the crown was used as a measure of cement retention. Cross head speed of Instron was 0.05 inch/ min. Retentive strength values were recorded and expressed in terms of MPa which was calculated as:

Retentive strength = Force

---------------

Surface Area

The surface areas of crowns have been determined by cut opening the crowns and developing their surfaces on graph papers. The areas of these developed surfaces have been determined by counting the number of squares on the graph sheet.

Results

The aim of the present study was to compare the retentive strengths of different luting agents and to know the effect of storage of samples in artificial saliva on the retentive strength of different luting cements.

ANOVA analysis of variance was used to compare the retentive strengths among different groups. Student ‘t’ test was used to compare the retentive strengths among same groups at different time intervals.

The ANOVA analysis revealed that there were significant differences in the retentive strengths of different cement groups.

The Retentive strength values of Zinc Phosphate cement, Rely X Luting II cement and Rely X ARC when tested at 1 day interval ranged from 1.8 – 2.6 MPa, 4.8 – 5.4 MPa and 7.5 –8.6 MPa respectively.

The retentive strengths values of Zinc phosphate cement, Rely X Luting II and Rely X ARC when tested after 7 days interval ranged from 1.7 – 2.3 MPa, 4.8 – 5.3 MPa and 7.5 – 8.5 MPa respectively.

The results showed that there was a significant decrease in the retentive strength values of zinc phosphate cement after 7 days of storage in artificial saliva (Table–6 & Bar Graph-6). The decrease in the retentive strength values of Rely X luting II and Rely X ARC after 7 days of storage were not significant.

Discussion

The introduction of Stainless steel crowns was a major breakthrough in the field of pediatric restorative dentistry. Its use has provided an effective and practical method of restoring teeth that otherwise could not have been retained. Many investigators have reported that stainless steel crowns are the most effective solution in restorations of primary molars with three or more caries affected surfaces [13],[1],[11].

The retention required for the clinical success of a stainless steel crown is unknown. It has been suggested by many clinicians that dental cement alone is responsible for the retention of stainless steel crowns on primary molars [9],[19]. Others believe that the significant retentive feature is the close adaptation of the metal crown margin to the tooth surfaces in the undercut areas of the prepared teeth [5],[2],[14].

Traditionally Zinc phosphate cement was used for luting stainless steel crowns. It is not an adhesive cement and has limited mechanical properties. Its retention is purely mechanical in nature. The mixing technique is critical in developing the optimal cement because the strength is almost linearly dependent on the powder liquid ratio. Pulp reactions to zinc phosphate have also been reported. This cement has been historically successful but clinical failures are often evident. So there was a need to select stronger luting agent than zinc phosphate cement.

Then emerged the era of Zinc polycarboxylate and Glass ionomer cements. These cements adhere chemically to tooth enamel and dentin as well as to stainless steel[6],[10]. Conventional luting GICs have shown satisfactory results[3],[4]. The main advantage of glass ionomer cement is that they release fluoride from the set cement[15]. The fluoride can be eluted as a simple ion or as a complex such as fluorophosphates and is considered to be of clinical benefit[20]. Two inherent drawbacks of Glass ionomer cements viz. Moisture sensitivity and low early strength are the result of slow acid-base setting reactions[16]. Therefore these cements are more susceptible to hydrolytic degradation. Isolation and protection of unset cement may be more critical. So polymerizable functional groups can be added to GICs to impart rapid curing when activated by light or chemicals to overcome these two draw backs.

Today materials which are gaining popularity include the Resin modified glass ionomer cements (Hybrid Ionomers), the Compomers and the Adhesive resin cements. Due to the importance of this research area and the scarcity of studies that evaluate the clinical success of these newer materials with stainless steel crowns, the purpose of the present study was to compare the retentive strengths of these newer adhesive cements with that of the conventional zinc phosphate cement.

Primary molars were selected for the study as stainless steel crowns are more widely used in primary molars to prevent premature tooth loss and development of further malocclusion.

Pretrimmed and precontoured stainless steel crowns were used in this study to standardize the surface area of the crowns as in case of other type of crowns trimming is necessary which gives an intra clinician variation in surface area.

| Table â 1 Retentive Strengths Of Different Groups At 1 Day And 7 Days Interval Inmpa

|

| Table â 2 Analysis Of Variance Among Different Groups At 1 Day Interval. Anova Table For Retentive Strength At 1 - Day

|

| Table â 3 Analysis Of Variance Among Different Group At 7 - Days Interval. Anova Table For Retentive Strength At 7 Days Interval

|

Instron Universal Testing Machine (UTM) was used in this study to measure the retentive strength of the cements because of its easy availability. Instron Tensometer and Hounsfield tensometer can also be used to measure the retentive strength of cements. The specimens were stored in prepared artificial saliva because it simulates human saliva.

The present study reveals that there was a statistically significant difference between the retentive strengths of three different groups of luting agents. The Adhesive resin cement Rely X ARC (Group C) possessed the maximum value of retentive strength followed by RMGIC Rely X Luting II (Group B) cement and zinc phosphate cement (GroupC).

The adhesive cements do not have a long clinical track record as zinc phosphate cement. There are very few studies that have compared these new classes of adhesive cements. They were selected for the present study because they are relatively newer in the field of Pedodontics, although they have been used more widely in fixed prosthodontics.

To improve the physical and mechanical features of conventional GICs, RMGICs combining both the resin and glass ionomer technologies have been developed. These RMGIC harden by an acid-base reaction between fluoroaluminosilicate glass powder and an aqueous solution of polyalkenoic acids. These materials have early moisture sensitivity which has been related to the presence of poly HEMA and unconverted monomer in the setcement[7]. One noted change from conventional GICs is the improvement of translucency because the inclusion of monomer brings the refractive index of the liquid close to that of the particle. In vitro testing of RMGIC indicates a fluoride release at the same level as conventional GICs.

The mechanism of bonding to tooth structure is the same as that of conventional GICs. These have greater compressive and diametrical strengths as compared to zinc phosphate cement and Glass ionomer cements[60]. This increase in strength is mainly attributable to their lower elastic modulus and the greater amount of plastic deformation that can be sustained before fracture occurs.The retentive strength values of RMGIC were significantly higher than zinc phosphate cement both at 1 day and 7 days interval.

Besides RMGIC, another class of luting agent used in this study was Adhesive Resin cement (Rely X ARC) which is a dual cure adhesive resin cement.Resin cements are essentially flowable composites of low viscosity. The dual cure cements are two-component systems and require mixing in a manner similar to that used for chemically activated systems. Chemical activation is very slow and provides extended working time until the cement is exposed to the curing light, at which point the cement hardens rapidly.

Some advantages of resin cements are insolubility in the oral environment, adequate consistency and film thickness, superior mechanical properties[8],[21], optimal bonding to dental structures and restoring materials by adhesive systems and reduced micro-leakage. These cements exhibit highest retentive strength values.

In the present study Rely X ARC i.e. Group C cement possessed the maximum retentive strength values when compared to Group B cement RMGIC and Group A cement Zinc phosphate both at 1 day and 7 days interval. Similar results were observed by William D Browning et al.

Another important point of discussion is the effect of duration of storage of teeth samples in artificial saliva on the retentive strength of different luting cements.

When the 1 day and 7 days results were compared, only zinc phosphate cement had significant decrease in the retentive strength values. Among the other cements i.e. Rely X luting and Rely X ARC no statistically significant differences (p<0.05) were established using the student ‘t’ test. This can be explained on the basis that the solubility of zinc phosphate cement in saliva and other oral fluids is more as compared to other materials. So its strength decreased after a storage period of 7 days in artificial saliva.

References

1. Einwag J, Dunninger P. Stainless steel crown versus multisurface amalgam restoration: An 8year longitudinal study. Quintessence Int 1996; 27(5): 321-323.

2. Full C.A, Walker J.D and Pinkham J.R. Stainless steel crowns for deciduous molars. J Am Dent Assoc 1974; 89: 360-364.

3. Godoy F.G, Bugg J.L. Clinical evaluation of glass cementation on stainless steel crown retention. J Pedodon 1987; 11: 339-343.

4. Godoy FG, Landry JK. Evaluation of stainless steel crowns luted with a glass ionomer cement. J Pedod 1989; 13: 328-330.

5. Henderson, Hala Z. Evaluation of the preformed stainless steel crown. J Dent Child Sep-Oct 1973; 40: 353-358.

6. Hotz P, McLean J.W, Sced I, Wilson AD. The Bonding of Glass Ionomer cements to Metal and Tooth substrates. Brit Dent J 1977; 142: 41-47.

7. Kanchanavasita W, Austice HM, Pearson GJ (1997). Water sorption characteristics of RMGIC. Biomaterials 1997; 18(4): 343-349.

8. Li ZC, White SN. Mechanical properties of dental luting cements. J Prosthet dent 1999; 81(5): 597-609.

9. Mathewson RJ, Lu KH, Rezi T. Dental cements Retentive Force comparison on stainless steel crowns. J Calif Dent Assoc 1974; 2: 42-45.

10. Mc Cabe, Jones J.F, Wilson H.J. Some properties of a glass ionomer cement. Brit Dent J 1979; 146: 279-281.

11. Mc Donald R.E. Avery DR. Restorative Dentistry In: McDonald RE, Avery DR. Dentistry for child and adolescent.7thed, St.Louis:Mosby, 2000; 384-412.

12. Messler LB, Levering NJ. Stainless steel crowns: Durability and prediction of success. J Dent Res 1987; 66: 213-217.

13. Messler LB, Levering NJ. The durability of primary molar restorations: II Observations and predictions of success of stainless steel crowns. Pediatr Dent 1988; 10(2): 81-85.

14. More J.G, Pink T.C. The Stainless steel crown: Clinical guide. J Mich Dent Assoc 1973; 55: 273-276.

15. Muzynski B.L, Greener E, Jameson L, William F.P. Fluoride release from glass ionomers used as luting agents. J Pros Dent July 1988; 60: 41-44.

16. Phillips’ Science of Dental Materials. 11th ed; Saunders; Elsevier:2003.

17. Powers JM. Cements In: Craig RG, Powers JM. Restorative Dental Materials. 11th ed. St. Louis: Mosby 2002; 593-634.

18. Robert H. Spedding. Two Principles for Improving the Adaptation of Stainless Steel Crowns to Primary Molars. DCNA Jan1984; 28(1): 157-174.

19. Savide N.L, Caputo A.A and Luke L.S. The Effect of Tooth Preparation on the Retention of Stainless Steel Crowns. J Dent Child Sept-Oct 1979; 46: 385-390.

20. Swartz M.L et al. Long term fluoride release from Glass ionomer cements. J Dent Res 1984; 63: 158-160.

21. White S.N, B Dent Sc, Zhaokun Yu. Compressive and diametrical tensile strengths of current adhesive luting agents. J Prosthet Dent 1993; 69(6): 568-572.

|