Introduction

In ancient times around 3000 B.C, antiseptics such as pitch or tar, resins & aromatics were used by Egyptians. The fumes of burning chemicals were also used as disinfectants. In 1683 Antonj Van Leuwenhoek developed microscope and proved the existence of microorganisms. The research of Robert Koch in 1881 on disinfecting properties of steam and hot air mark the beginning of science of disinfection. Infection control is a cardinal issue in dental practice.[1] As dental professional we are exposed to a wide spectrum of microorganisms in blood and saliva of patient. Dental treatment procedures starting with making of impression may be the first link in microbial contaminate on. American Dental Association (A.D.A) & Centre for Disease Control (C.D.C) recommend disinfection of impression materials before being transported to the laboratory.[1],[2]

The present study is an attempt to find the most suitable immersion disinfectant which causes least dimensional changes and preserves impression’s property of reproducibility.

Materials & Method

The present in-vitro study was done by immersing different brands of irreversible hydrocolloid in disinfectants for different intervals. All samples were divided into four major groups. Each group was further subdivided into two subgroups A & B.

Subgroup A-Represented samples for determining dimensional accuracy.

Subgroup B- Represented samples for determining reproducibility.

Subgroups A & B were segregated into three minor subgroups according to disinfectants (a, b, c). Each minor subgroup had 15 samples.

a - Glutaraldehyde

b - Povidone Iodine

c - Sodium Hypochlorite

Each minor subgroup was further divided into three parts. Each part had 5 samples.

Part I-Immersion in disinfectant for 5 minutes.

Part II-Immersion in disinfectant for 10 minutes

Part III-Immersion in disinfectant for 15 minutes

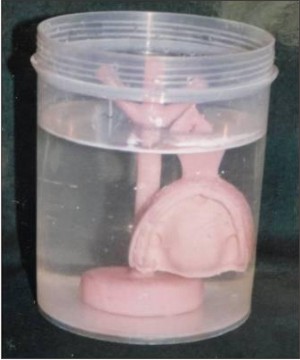

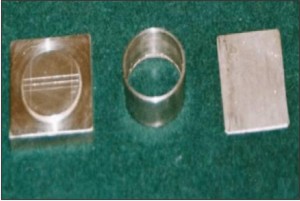

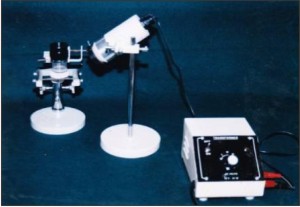

For subgroup A a custom tray was fabricated with acrylic resin. Acrylic tray hanger was fabricated (Fig 1). A metal Die with three cones (namely A, B, C) as shown in (Fig 2) was fabricated. For subgroup B a steel Block containing engraved lines of 25, 50, 75 micrometer width was fabricated (Fig 3). A metal ring was made to carry the impression material to the test block and a flat metal plate was used to press the impression material on the ring placed on block. A total of 180 samples were made for subgroup A & B each. Travelling Microscope (Fig 4) with a least count of 0.01 mm was used for measuring dimensional stability in subgroup A. Distances between points A, B & C were measured. For subgroup B a comparator mounted with X10 magnification lens was specially designed. A low angle illumination with a light source attached to a transformer was used for viewing lines of samples (Fig 5). Samples in subgroup A, & B were made by making impression of respective dies, pouring impression with die stone. Control impressions were poured immediately (Fig 6).

expression of results for Dimensional accuracy was done by determining change in percentage mean area. Reproducibility was determined by evaluating lines by following criteria-

Score 1- Continuous well defined sharp line was reproduced.

Score 2- Continuous line with loss of sharpness.

Score 3- Break in continuity of line.

Score 4- No line reproduced.

Disinfectant showing maximum stability with minimal change in percentage area & also preserving the impression property of reproducibility was determined. Statistical Analysis used Mean, ANOVA test& Newman Keuls test for individual comparison of groups.

| Fig 1 - Acrylic Tray Hanger with Impression

|

| Fig 2 - Die for evaluating Dimensional accuracy

|

| Fig 3 - Die for determining Reproducibility

|

| Fig 4 - Travelling Microscope

|

| Fig 5 - Comparator

|

| Fig 6 A - Samples for evaluating Dimensional accuracy

|

| Fig 6 B - Samples for determining Reproducibility

|

Results

Results showed that for 5 minutes immersion in disinfectant, 75% samples of irreversible hydrocolloid show least dimensional changes with Sodium Hypochlorite compared to other disinfectants. For 10 minute immersion 50% samples show least dimensional changes with sodium hypochlorite. For 15 minute immersion 50% samples of irreversible hydrocolloid show least dimensional changes with sodium hypochlorite.

No particular disinfectant was found to favor all three dimensions.

Long span dimension distorted more than short span dimensions.

Reproducibility was comparatively not affected by time period selected for immersion.

Discussion

A number of microorganisms in the dental environment have been linked to debilitating & life threatening diseases. Every effort must be made to avoid cross contamination of these microorganisms & to prevent the potential transfer of disease in a dental setting. Accuracy & surface detail of impression should never be compromised. The use of A.D.A accepted disinfectants require 5 to 30 minutes of immersion disinfection. Immersion in Hypochlorite Iodophors or Glutaraldehyde is recommended by Council on dental materials, instruments & equipments.

John A Molinari[1] stated that Centre for Disease Control has recommended use of 0.05% to 0.5% Sodium Hypochlorite as an effective agent in inactivating Hepatitis B Virus. Glutaraldehyde which is A.D.A accepted has high Biocidal activity. Iodophores have tuberculocidal activity within 5 to 10 minutes of exposure. Xavier Lepe[3] stated that immersion & spray disinfection of the impression are more popular methods than cast disinfection. Immersion disinfection is more reliable than spray disinfection because it guarantees that all surfaces of impression will come into contact with the disinfectant solution. John B Tullner[4] studied reproducibility for irreversible hydrocolloid impression material by immersion in disinfectant for 5, 10 & 15 minutes by using test block engraved with 25, 50 & 75 micrometer width lines. Finest line of 25 micro-meters was used as criteria line. Individually for each dimension disinfectants have a variable effect. No particular disinfectant was found to favor all three dimensions, indicating that there may be a cause in chemistry of alginate impression material that caused more leaching of ions from gel structure, disrupting the chemical bonds, thus leading to distortion of alginate this is in accordance with study of Setsuo Saito[5] who stated that disinfectant by changing osmotic pressure causes leaching of monovalent and divalent metallic ions from alginate impression material leading to distortion of impression. It was observed that cross-arch dimension had a less significant effect than intra arch dimensions on mean percentage change in area i.e dimensional accuracy. This is in accordance with the study of Herrera & Merchant[6] who found that maximum cross arch diameter and canine to canine dimension were not significantly affected by immersion disinfection. Long span dimension distorted more than short span dimension. This is in accordance with study of J F Burton[7] who stated that short span impressions appeared to be far less sensitive to distortion than long span impressions regardless of cause. In the present study, it was observed that comparatively time of immersion did not have a significant effect on reproducibility. Variations in results of reproducibility could be in accordance with study of D.H Pratten[8] who stated that disinfectant treatment alters the surface chemistry of impression material changing the hydrophillicity of impression material, rendering impression more wettable or less wettable by slurry of gypsum.

The models obtained after immersion disinfection of impression material were either larger or smaller than the control group models; this may affect the prosthesis fit. Large size models can be beneficial in providing space for luting cements in fixed Prosthodontics and also for compensation of shrinkage of gypsum during setting. If this factor of model size could be controlled and utilized for counteracting the setting expansion of die stone & casting shrinkage of metals than the accuracy of prosthesis could be improved, thus disinfectant could be provided with beneficial effect of removing microorganisms & improving the fit of prosthesis.

Conclusion

Distortion of an impression is not caused by material alone. Dimensional accuracy and Reproducibility did not differ significantly for 5,10,15 minutes immersion .The decision in selecting type of impression material depends on individual preference, experience or needs of dentists. Factors such as handling, working characteristics, patients comfort or economics help to determine the choice of impression material. Further studies may be done to determine potency of disinfectants and effect of many other factors, such as relaxation of stresses, excessive seating pressure and impression technique. Threat of cross infection is raising a challenge to profession. Research & Practice is one small step to meet the challenge.

References

1. Molinari JA. Role of disinfectants in infection control. D Clin North Am 1991;35.

2. Craig RG, O Brien JW, Power JM. Dental Materials, 5th ed, 1996; 150-1.

3. Lepe X, Johnson GH et al. Surface characteristics of polyether and addition silicone impression materials after long term disinfection. J Prosthet Dent 1995;74:181-6.

4. Tullner JB, James et al. Linear dimensional changes in dental impression after immersion in disinfectant solutions. J Prosthet Dent 1988;60:725-8.

5. Setsuo Saito. Factors affecting dimensional stability of alginate impression during immersion in the disinfecting solution. Dent Material J1998;17(4):294-300.

6. Herrera SP, Merchant VA. Dimensional stability of dental impressions after immersion disinfection. J Am Dent Assoc1986;113:419-22.

7. Burton JF. The effect of disposable and custom made impression trays on accuracy of impressions. J Dent 1989;17:121-3.

8. Pratten DH, Covey DA et al. Effect of disinfectant solutions on the wettability of elastomeric impression materials. J Prosthet Dent 1990;63:223-7.

9. Agar JR, Law DB et al. An impression tray hanger for disinfection. J Prosthet Dent 1990;63:597-9.

10. Carlyle LW. Compatibility of irreversible hydrocolloid impression materials with dental stones. J Prosthet Dent1983;49:434-7.

11. Drennon DG, Johnson GH. The effect of immersion disinfection of elastomeric impressions on the surface detail reproduction of improved gypsum casts. J Prosthet Dent1990;63:233-41.

12. Gehl DH, Payne SH. Compatibility of Alginate impression materials & dental stones. J Prosthet Dent1971;25:556-7.

13. Kahn RC, Lancaster MV et al. The microbiologic cross contamination of dental prosthesis. J Prosthet Dent1982;47:556-9.

14. Stern MA, Whitcare RJ. Avoiding cross-contamination in Prosthodontics. J Prosthet Dent 1981;46:120-2.

15. Tjan AHL, Wharg SB et al. Clinically oriented evaluation of the accuracy of commonly used impression materials. J Prosthet Dent1986;56:4-8.

16. Watkinson AC. Disinfection of impressions in U.K Dental Schools. Br Dent J 1988;22-3.

|