Introduction:

Dental professionals are at an increased risk of cross contamination during treatment procedures as they are exposed to variety of microorganisms in blood and saliva of the patients[1].

The spray disinfecting technique for stone casts appears to eliminate the surface details and strength problems associated with immersion of casts. The potentially damaging effects of immersion technique and the difficulty in covering the entire surface have led to the need for incorporating a disinfectant directly into the die stone[2]. The present study aims at evaluating the setting time and surface detail reproduction of die stone after mixing with different disinfectant solutions.

Material and Methods:

The study was carried out in accordance with ADA Sp. No. 25[3], which states that tests related to gypsum products are to be conducted at a room temperature of 230C ± 20C and relative humidity of 50% ± 10%. Aqueous solutions of 2 chemical disinfectants were used for mixing die stone. The study included comparative evaluation of three groups of specimens namely group 'A' (distilled water), group 'B' (2% Glutaraldehyde) and group 'C' (5% Sodium hypochlorite). Thus a total number of 60 specimens, 20 in each test group were prepared and were evaluated for setting time as well as for surface detail reproduction. Setting time was determined by using Vicat apparatus (Figure 1). Setting time was evaluated through the insertion of a metallic needle (1 mm diameter, 50 mm length), connected to a vertically mobile aluminum rod, under a total weight of 300 g. An aluminium ring with an internal diameter and height of 25 mm was attached to a circular glass plate and placed at the base of the Vicat apparatus. The die stone was shed into the ring, for the gauging of the setting time. The needle was then placed at a distance of 0.5 mm from the gypsum surface, and abruptly set free 2 minutes before the mass lost its superficial shine, thus allowing the complete insertion of the needle. After this, sequential insertions were carried out every 15 seconds in different areas, until the needle could not fully penetrate the mass any longer. The time spent between the beginning of the mixing to the point where the needle could not fully penetrate the mass any longer was measured with a digital stop watch and thus the Vicat setting time was obtained.

For the analysis of the reproductive capacity of die stone, aluminium plate was fabricated with lines scribed at

| Figure 1-Vicat Apparatus used for setting time evaluation

|

| Figure 2-Aluminum Metal Die with Cylindrical ring

|

| Figure 4-Evaluation of specimen for Surface Detail Reproduction as viewed under Stereoscopic microscope.

|

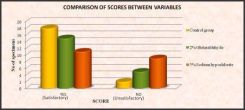

| Figure 6-Graphical representation of Chi-square test showing the number of specimens with satisfactory surface detail reproduction and unsatisfactory surface detail reproduction.

|

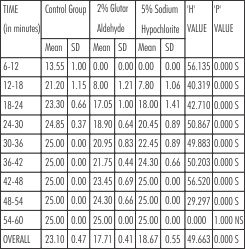

| SETTING TIME: TABLE -1 Statistical analysis of three groups i.e, Distilled water, 2% Glutaraldehyde and 5% Sodium hypochlorite using Kruskal-Wallis H test.

|

| Surface Detail Reproduction: TABLE -2 Statistical analysis of three groups i.e, Distilled water, 2% Glutaraldehyde and 5% Sodium hypochlorite using Chi-square test

|

different depths varying from 0.025 to 0.300 mm. An aluminium ring with 30 mm diameter and 15 mm height was fixed with cyanoacrylate over the aluminium plate, such that the 0.050 mm depth line remained centered on the ring (Figure 2). After the die stone was mechanically mixed under vacuum with each disinfecting solution, it was subsequently poured under vibration into the cylindrical ring. After 2 hours, the specimens were removed, and the surface was analyzed in a stereoscopic microscope at 10X magnification (Figure 3). Detail reproduction was considered satisfactory when a copy of the 0.050 mm line appeared along the whole diameter of the ring (Figure 4).

Results:

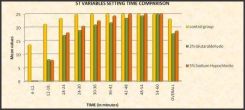

The obtained values for setting time were statistically analyzed using Kruskal-Wallis H test (Table 1). The Kruskal-Wallis H test was used to compare all the three groups and the results showed that the Group 'C' values were similar to that of Group 'A' i.e., control group when compared to Group 'B' (Figure 5). Thus the specimens prepared with 5% sodium hypochlorite showed similar setting time values with that of control group.

The obtained values for surface detail reproduction were statistically analyzed using Chi-square test (Table 2). According to which, the Group 'B' resulted in values similar to that of Group 'A' i.e., control group when compared to C group (Figure 6). Thus the specimens prepared with 2% glutaraldehyde showed better surface detail reproduction similar to that of control group.

Discussion:

Interaction between dental clinic and dental laboratory personnel is intrinsic in practice of general dentistry. Transmission of infected materials from the clinic to the laboratory and then back to clinic not only place unaware staff at risk, but also results in high level of cross-contamination. Research over the past have demonstrated that microorganisms can be transferred from the stone casts to dental personnel handling the casts in first 24 hrs, following separation from the contaminated impressions. To overcome this, several methods have been proposed to disinfect the impressions and cast satisfactorily. According to guidelines proposed by ADA council (1996)[4], it is recommended that the impressions should be rinsed under running water to

[Image 3]

| Figure 5-Graphical representation of Kruskal-Wallis H test. The obtained setting time values are plotted against the time intervals.

|

remove saliva and to perform immersion disinfection using any compatible disinfectant for varying lengths of time. The techniques recommended for disinfecting dental casts include immersion or a topical spray with a disinfectant solution.

However Rudd et al (1970)[5], showed that immersing a stone cast in tap water alone for 15 minutes altered surface properties. Since it is recommended that a cast should remain submerged in the solution for up to 30minutes to achieve a disinfected surface, it is probable that there will be a negative effect on the surface integrity of the cast.

Sarma and Neiman[6] testcd the effects of immersion disinfection of stone casts with various glutaraldehyde, phenol, iodophor, and chlorine disinfectants. They found that sodium hypochlorite produced the fewest undesirable effects with regard to surface erosion, surface hardness, compressive strength, and chemical reactivity with the casts.

The spray technique for disinfecting the surface of stone casts appears to eliminate surface detail reproduction & strength problems associated with immersion of casts in unsaturated solutions. M.A.Stern et al (1991)[7], conducted a study on different disinfectant sprays for disinfecting the casts and stated that the problem with spray disinfectants is the inability of the solution to completely cover and maintain contact with all surfaces of the cast for the required amount of time.

Hence an alternative approach to cast immersion and spray disinfection i.e, incorporating disinfectants into gypsum at the time of its mixing has been proposed. Studies have shown that incorporation of disinfectants into gypsum at the time of mixing produced a significant and acceptable reduction in the number of bacteria. This indicates that addition of disinfectants to gypsum may be useful method to disinfect both the cast and impression.

According to L.G.Breault et al[8] Substitution of a 5.23% solution of sodium hypochlorite in place of 10% of the gauging water when mixing a Type V stone resulted in an increased compressive strength and rigidity.

Donovan and Chee[9] conducted a study to evaluate the physical properties of the disinfectant containing die stone and compare these properties with those of two commonly used die materials and concluded that there is decrease in setting time compared to control group.

M.G.Lucas et al (2009)[10] conducted a study on setting time and concluded that incorporation of 2% Glutaraldehyde solution showed similar results to that of control group as the results obtained are within the limits of ISO standards.

The present study was done to evaluate and compare three groups of specimens namely group 'A' (distilled water), group 'B' (2% Glutaraldehyde) and group 'C' (5% Sodium hypochlorite) mixing with the die stone material. The specimens were evaluated for setting time using standardized Vicat apparatus. Statistical analysis revealed 5% Sodium hypochlorite, 2% Glutaraldehyde showed increase in setting time by 10-15min when compared with that of control group.

The specimens for surface detail reproduction were evaluated using stereoscopic microscope. M.G.Lucas et al conducted a study on surface detail reproduction and concluded that incorporation of 2% Glutaraldehyde solution presented results which are similar to the control group.

The various ADA recommended concentrations of Sodium hypochlorite for disinfection are 0.5%, 1%, 2%, 5% and 5.25%. However all the previous studies done so for used only lower concentrations of Sodium hypochlorite to evaluate their effect on the physical properties of Gypsum products. The effect of 5% Sodium hypochlorite was not evaluated to greater extent.

In this study 5% Sodium hypochlorite was substituted for gauging water to mix with die stone and the specimens were tested for both setting time and surface detail reproduction. The statistical analysis of the results achieved, showed that there is an increase in setting time of the die stone and surface detail reproduction of the die stone was affected adversely.

Conclusions:

Within the limitations of this study the following conclusions can be drawn

Setting Time:

1. The setting time of die stone increased when mixed with 2% Glutaraldehyde compared to the control group.

2. The setting time of die stone was similar to that of control group when 5% Sodium hypochlorite was used as disinfectant solution.

3. The setting time of die stone was increased when 2% Glutaraldehyde was used as disinfectant solution compared to 5% Sodium hypochlorite.

Surface Detail Reproduction:

1. The surface detail reproduction capacity of die stone was similar with that of control group when 2% Glutaraldehyde was used as disinfectant solution.

2. The surface detail reproduction capacity of die stone was adversely affected when 5% Sodium hypochlorite was used as disinfectant solution when compared to control group.

3. The surface detail reproduction capacity of die stone was less affected by 2% glutaraldehyde when compared to 5% Sodium hypochlorite.

References :

1. R. R. Runnells, An overview of infection control in dental practice. Journal of prosthetic dentistry 1988;59(5):625-9.

2. Gelson Luís Adabo, Elaine Zanarotti,R Enata Garcia Fonseca, Effect of disinfectant agents on dimensional stability of elastomeric impression materials. Journal of prosthetic dentistry 1999; 81:621-4.

3. American Dental Association: Specification No. 25 for dental gypsum products. In ADA: Guide to Dental Materials and Devices. Journal of American Dental Association, 1972/1973, pp. 253-258.

4. ADA Council, Infection control recommendations for the dental office and the dental laboratory .Journal of American Dental Association 1996; 127: 672 - 680.

5. Rudd KD, Morrow RM, Brown CE Jr, Powell JM, Rahe AJ, Comparison of effects of tap water and slurry water on gypsum casts. Journal of Prosthetic Dentistry 1970; 24:563-70.

6. Sarma AC, Neiman K: A study on the effect of disinfectant chemicals on the physical properties of die stone. Quintessence international 1999;2:53-59

7. Stern MA, Johnson GH, Toolson LB, An Evaluation of dental stones after repeated exposure to spray disinfectants. Part I: Abrasion and Compressive strength. Journal of Prosthetic Dentistry 1991; 65:713-8.

8. Breault LG, Paul JR, Hondrum SO Die stone disinfection: Incorporation of sodium hypochlorite.Journal of Prosthodontics 1998;7:13-16

9. Donovan T, Chee WW Preliminary investigation of a disinfected gypsum die stone. International Journal of Prosthodontics 1989;2:245-248.

10. M.G. Lucas, J.N.Arioli-Filho,S.Nogueira, A.U.D.Batista, R.P.Pereira, Effect of Incorporation of Disinfectant Solutions on Setting time, Linear Dimensional Stability and Detail Reproduction in Dental Stone Casts. Journal of Prosthodontics 2009;18: 521-526. |