Introduction

'Luting' is a word that is often used to describe the use of a moldable substance to seal a space or to cement two components together. They can also be described as the use of a flowable substance to seal joints and cement two surfaces together. Traditionally, the term 'Cements' in dentistry has been applied to a powder liquid material which when mixed to a creamy consistency sets to a hard mass which is used clinically to join the restoration to the teeth. Cements have been used in restorative dentistry for luting purposes for a long period of time. However, since the properties of various cements differ from each other the choice of cement depends on a larger degree to the functional and biological demands of the particular clinical situation. If optimal performance is to be attained, the physical and biological properties along with working characteristics like manipulation time, working time and ease of removal of excess flash must be considered when selecting cement for a specific purpose. Solubility is one of the most important essential factors in assessing the quality of luting agents in restorative dentistry. Generally the luting cements require an extended setting time and a working time which makes them more susceptible to intraoral saliva contamination[1].Early cement exposure to saliva during setting of cement not only alters most of its properties, especially solubility and resulting in microleakage and affecting durability of the restoration. Luting cements have been known to undergo early dissolution when exposed to moisture immediately after initial hardening. Prevention of moisture contamination is therefore necessary[2].

However, even with utmost care, sometimes it is not possible to have a moisture free environment when rubber dam is not applied. During the recent years, several luting agents have been introduced, each claiming superiority over the other. The physical properties of these cements after exposure to oral fluids during cementation are a matter for serious concern. A number of materials are available for cementation purposes. These include zinc phosphate, silicophosphate, polycarboxylate, glass ionomer, zinc oxide-eugenol (ZOE), and resin-based cements. Several factors have an influence on the retention of fixed prosthesis through the use of these luting agents [3].First, the film thickness beneath the prosthesis should be thin. It is believed that a thinner film has fewer internal flaws compared with a thicker one [4]. Second, the cement should have high strength values. Generally, greater forces are required to dislodge appliances cemented with cements that have higher tensile strength than with cements with low tensile strength. Other factors like, compressive and shear strength of the cement, fracture toughness and film thickness also play an important role [4, 5].Third, the dimensional changes occurring in the cement during setting should be minimized. Sources include, gain or loss of water and differences in the coefficients of thermal expansion among the tooth, the prosthesis, and the cement [6, 7]. It is, therefore, important to isolate the cement immediately after removal of the excess [4].

Fixed prosthesis can debond because of biologic or physical reasons or a combination of the two. Recurrent caries results from a biologic origin [8].Disintegration of the cements can result from fracture or erosion of the cement. In the oral environment luting cements are immersed in an aqueous solution [6]. In this environment, the cement layer near the margin can dissolve and erode leaving a space. This space can be susceptible to plaque accumulation and recurrent caries; therefore the margin should be protected with a coating to allow continuous setting of the-cement [9].

A study was therefore undertaken to compare the solubility of some of the conventional luting cements during their initial contact with water or moisture. In this study, solubility of four types of luting cements during initial moisture contamination and effect of time lapse between mixing and moisture contamination on solubility of these four luting cements is being compared.

Material And Methods

The conventional specification test for assessing the solubility and disintegration of dental cements was developed by Paffenbarger et all [18, 19] It consists of immersing 2 thin flat disks of cement in water 1 hour after preparation. Twenty-four hours later, the disks are removed from the water and the water evaporated to dryness. The amount of material lost is determined from the weight of the residue and is usually expressed as a percentage of the original weight of the cement. This method consists of the basis of solubility evaluations because the organic or polymeric materials that might be collected would not have been degraded or volatilized during the drying steps. The conventional method was originally intended for the quality control of commercial products. However, the method has often been altered by research workers to evaluate new materials and to compare different types of dental cements. [15, 16, 17] Um and Øilo [15] altered the conventional method to evaluate the solubility of luting cements at the early stages after mixing. Instead of thin flat disks, they used resin molds as cement holders and immersed cements in distilled water at the early stages of mixing before the final set of the cement. The same method, except immersion times and immersion in artificial saliva [14] was used in this study to record the early solubility of luting cements.

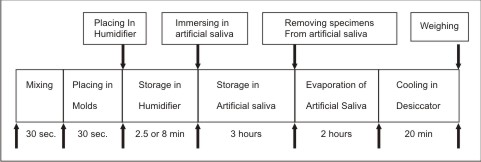

| Flow Chart 1. Time Schedule For Experimental Procedure.

|

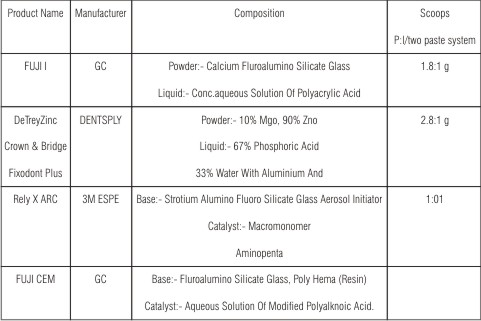

| Table 1

|

To quantify loss of substance from 4 different luting cements (Table 1), 2 circular cavities (diameter of 5 mm, depth of 2mm) were made in resin block (fig 2). The cements were all mixed on a glass slab at room temperature by the stiff blade. The powder/liquid ratios used were in accordance with the manufacturers' recommendations. If the powder/liquid ratios were not given in the instructions, they were calculated from the proportioning system given by the manufacturer by weighing scoops of powder or drops of liquid. The powder/liquid ratios of each cement are given in Table 1. In each case, the powder was weighed on a digital balance (fig 3) that had a measuring accuracy of 0.1 mg and the liquid was dispensed from a 1 mm tuberculin syringe calibrated to the nearest 0.1mL. All cements were mixed within 30 seconds and placed in small resin cups in 30 seconds. The surface was flattened all the excess cement was removed with a spatula and a dry cotton pellet. One minute after the start of mixing, the specimens were placed in a humidifier (fig 4) at 37°C and 100% relative humidity. After 2, 5, or 8 minutes of storage time, specimens were removed from the humidifier and immersed in 50 ml of artificial saliva in a glass weighing bottle with the exposed surface area pointed upward.

The mass of the empty bottle had been previously established by using a digital balance that had a measuring accuracy of 0.1mg. Before weighing, the bottle was carefully rinsed, dried at 130°C for 2 hours in hot air oven (fig 5), and cooled in a desiccation for 20 minutes. Bottles were stored for 3 hours at 37° C and thereafter, the cement holders were removed from the water and the bottles were stored at 130° C for 2 hours to allow evaporation of water. Bottles were then cooled in a desiccators (fig 6) and weighed as previously described. The amount of substance dissolved was determined by subtracting the first established weight of the bottle from the second. The time schedule for the total procedure is illustrated in Flow chart. Five specimen of each type of cement were used at each immersion stage. The mean weight loss per square centimeter was calculated. The exposed surface area of each specimen was calculated (r = 2.5 mm) and the exposed surface area was doubled as each cement holder had 2 cavities. Data were analyzed by 2-way analysis of variance (p<0.01). Duncan's multiple range test analysis was also used to distinguish statistically significant groups.

Results

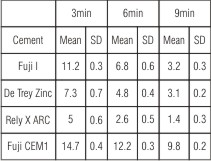

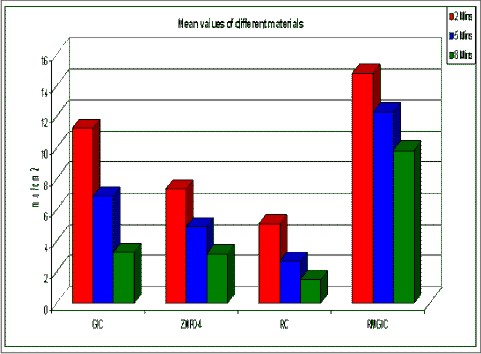

The recorded mean values and the standard deviations for each luting cements at each immersion time are presented in table 2.The lowest cement loss was recorded for resin cement after 9 minutes immersion time (1.47 mg/cm2). The greatest loss was for resin modified glass ionomer cement after 3 minutes immersion time (14.75 mg/cm2). For all of the observed luting cements, resin cement showed the lowest mean loss of substance at all immersion times. However, the loss of resin cement was significantly different from all cement at 3 minutes immersion time. Increasing the time from the start of mixing until immersion in artificial saliva from 3 to 9 minutes resulted in marked decrease in loss of substance from the surface of all 4 cements (Graph 1.) This inter-comparison result was obtained from the "BONFERRONI". The solubility of the cement decreased by 33% for Fuji I, 33% for De Trey Zinc, 50% for Rely X ARC, and 17% for Fuji CEM at various timer intervals between the various groups. The pair wise comparison was done using the "ANALYSIS TEST". For all the four groups there is a significant reduction in solubility at 3 minutes versus 6 minutes and 3 minutes versus 9 minutes and 6 minutes versus 9 minutes. When the specimens were immersed in artificial saliva 6 minutes after mixing, the difference in solubility between 3 and 6 minutes was most marked for RC cement, which was around 50%.The percentage reduction in solubility at 5 minutes immersion time to be 45% for GIC, 40% for ZnP04, 41.7% for RC, and 28% for RMGIC cement. The degree of solubility of these cements from 2 minutes to 8 minutes from start of mixing was 71.2% for GIC followed by RC by 71.1%, 59.8% for ZnP04, and 33.3% for RMGIC.

| Table 2. Mean And Standard Deviations Of Loss Of Substance (mg/cm2) For 4 Luting Cements Immersed In Artificial Saliva At Different Intervals.

|

| Graph 1. Graphic Representation Of Solubility Of Luting Cements In Relation To Immersion Time.

|

Discussion

From the results obtained, it can be seen that the resin cement, gave the least solubility at all periods of time. This can be explained by the fact that principle cement is more of resin cement and less of glass ionomer cement. Also it has a dual cure capability and the margins can be light cured. The next ideal cement in terms of reduced solubility was the century old zinc phosphate cement. As far as its solubility was concerned, it was found less soluble than glass ionomer cement in our vitro study. Studies [2] have shown the importance of protecting the glass ionomer cements immediately after cementation, as they have been shown to disintegrate rapidly in the presence of moisture. Zinc phosphate showed a lower solubility than the glass ionomer cement, therefore it is necessary that adequate protection is given against water after cementation. The reason for the dissolution of glass ionomer cement in water has been attributed to two factors: firstly [2], they contain sodium that forms water soluble salts with the matrix forming anions. Secondly [2], free calcium and aluminum ions that are present in the fresh cement can be removed by chemical reactions. In addition, aluminum ions react rather slowly with the matrix forming anions and before they are bound, is vulnerable to early water leaching. As the setting progresses, the cement becomes more and more solid, preventing water penetration and reducing the outward transportation of cations.

Finally4, the resin modified glass ionomer cement showed the highest solubility which was more than glass ionomer cements. Because they contain a resin HEMA (hydroxy ethylmethacrylate) which is hydrophilic in nature, there is an increased water sorption and subsequent plasticity and hygroscopic expansion. This behavior is analogous to a synthetic hydrogel. All the four luting agents show a decreased amount of solubility when extending the time between the start of mixing and immersion in artificial saliva. A significant decrease was observed during a 2-8 minute period after commencement of mixing and the loss of substance was greatly reduced at 8 minutes after the commencement of mixing.

As regard, the percentage reduction of solubility from 2-8 minutes, we find that the resin modified glass ionomer cement showed the least reduction in solubility which can be explained as mentioned earlier due to the presence of HEMA resin. Although invitro tests have limited clinical significance because it does not give an indication of stability of the set cement in oral environment, they are important for screening the quality of different cement types.

Conclusion

From the results of this study the following conclusions were obtained. The resin cement showed the least solubility to water at various time intervals of immersion. Zinc phosphate and glass ionomer cement followed this to various time intervals of immersion. The resin modified glass ionomer cement showed the highest solubility. The glass ionomer cement showed a greater percentage of reduction in solubility as the time interval of immersion in water increased when compared to other luting cements. This study shows that the resin modified glass ionomer cement and glass ionomer cements requires protection from moisture in the early period after mixing (8 minutes).

References

1. NureEH and Canay S. In vivo solubility of three types of luting cement. Quintessence Int 1996; 27(3):211-216.

2. Deniz G, Binnaz Y, Ozcan M and Akumru HN. Effect of early water solubility of glass ionomer luting cements. J Prosthet Dent 1998; 80: 474-478.

3. Knobloch LA, Kerby RE, McMillen K and Clelland N. Solubility and Sorption of Resin-based luting cements. Journal of Operative Dentistry 2000; 25:434-440.

4. Diaz-Amold A, Vargas MA and Haselton DR. Current status of luting agents for fixed prosthodontics. J Prosthet Dent 1999; 81: 135-41.

5. Attar N, Tam LE and McComb D. Mechanical and physical properties of contemporary dental luting agents. J Prosthet Dent 2003; 89:127-34.

6. Nomoto R, and McCabe JF. Simple acid erosion test for dental water-based cements. Journal of Dental Materials 17; 2001: 53-59.

7. Michael S, Jacobs and Stewart A. An investigation of dental luting cements solubility as a function of the marginal gap. J Prosthet Dent 1991; 65: 436-42.

8. Yap A and Lee CM. Water sorption and solubility of resin-modified polyalkenoate cements. Journal of Oral Rehabilitation 1997; 24: 3 10-314.

9. Shane N, Ingles WS and Kipnis V. Influence of marginal opening on microleakage of cemented artificial crowns. J Prosthet Dent 1994; 71:257-64.

10. Baldissara P, Comin G, Martone F and Scotti R. Comparitive study of the marginal microleakage of six cements in fixed provisional crowns. J Prosthet Dent 1998; 80: 417-22.

11. Zuellig-Singer R and Roland WB. Three-year evaluation of computer-machined ceramic inlays influence of luting agent. Quintessence Int 1998; 29:573-582.

12. Lewinstein I, Fuhrer N and Ganor Y. Effect of a fluoride varnish on the margin leakage and retention of luted provisional crowns. J Prosthet Dent 2003; 89: 70-75.

13. Xin HG and Mathias K. Marginal Discrepancies and Leakage of All-Ceramic Crowns influence of luting agents and aging conditions. Int J Prosthodont, 2003; 16: 109-116.

14. Westerman G, Hicks J , Flaitz C. Argon laser curing of fluoride - releasing pit and fissure sealent : invitro caries development. journal of dentistry for children 2000; 6 :385-388.

15. Um Cm, Øg. The effect of early water contact on glass -ionomer cements. QuintessencInt 1992; 23:209-14.'

16. Øilo G. Early erosion of dental cement. Scand J Dent Res 1984; 92:539-43.

17. Beech DR, Bandyopadhyay S.A new laboratory method for evaluating the relative solubility and erosion of dental cements. J Oral Rehabil 1983; 10:57-63.

18. Paffenbarger GC, Swenny WT, Issacs A. Zinc phosphate cements physical properties and specification. J Dent Res 1934:21:1097-11.

19. Paffenbarger GC, Schoonova IC, Souder W. Dental silicate cements: physical properties and a specification. J Dent Res 1938; 25:32-87. |